Process method for refining austenitic manganese steel by blowing argon gas into medium frequency induction furnace

A process method and induction furnace technology, applied in the field of smelting wear-resistant manganese steel, can solve the problems of high gas content, deep molten pool, and low temperature, and achieve the effects of simplifying the operation process, uniform molten steel temperature, and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] The method of refining molten steel by blowing argon in the 5-ton alkaline intermediate frequency induction furnace without oxidation method for smelting manganese steel

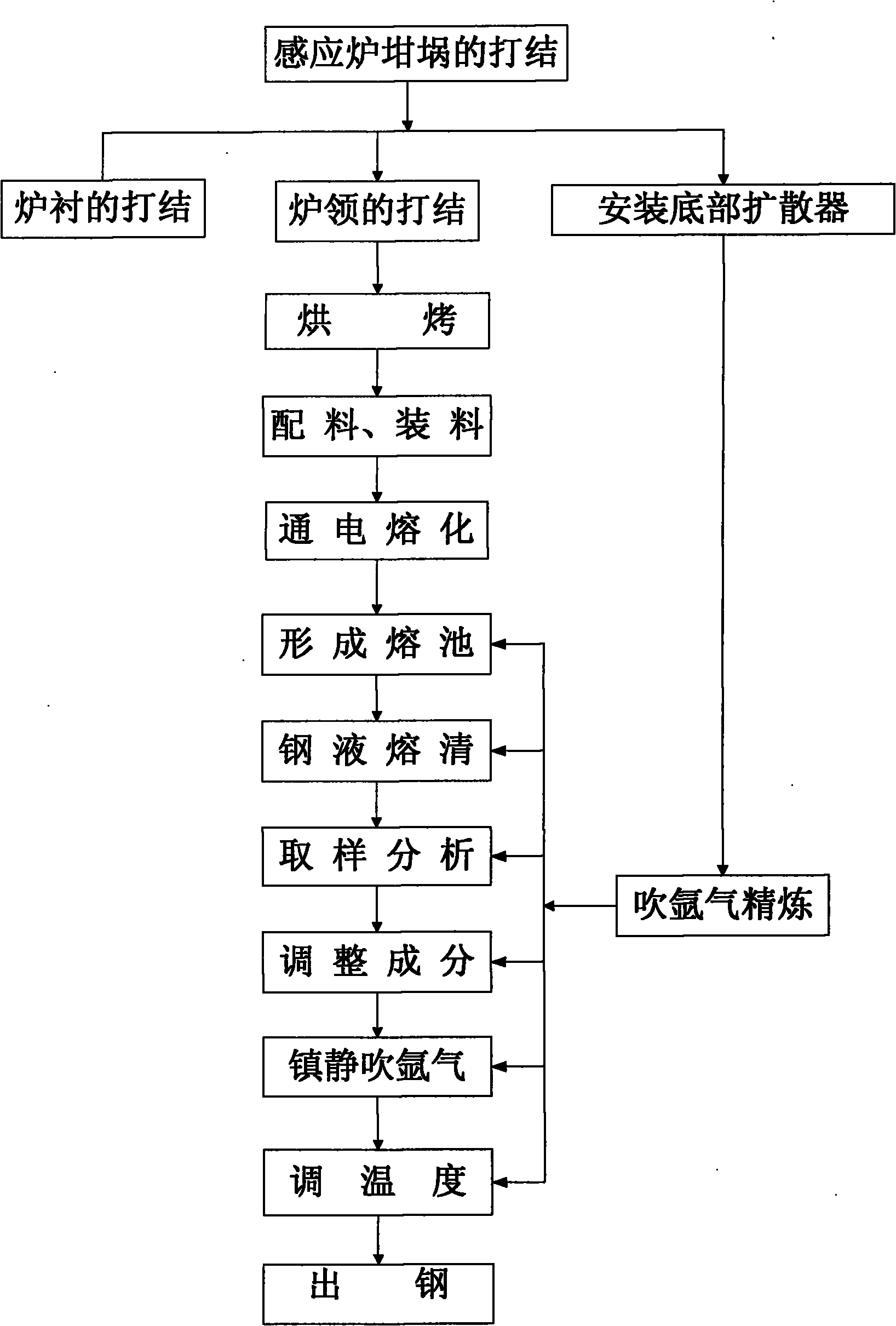

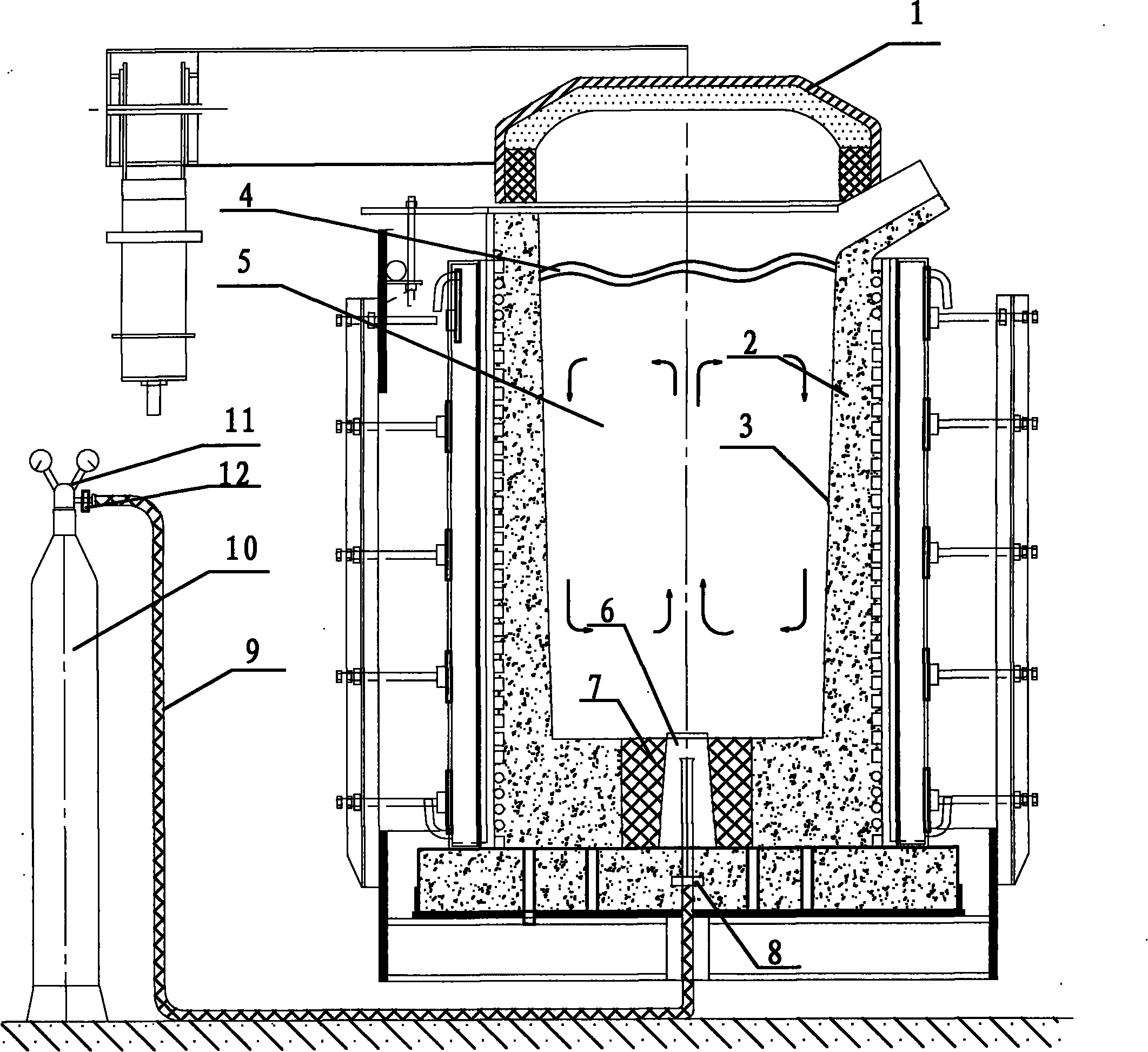

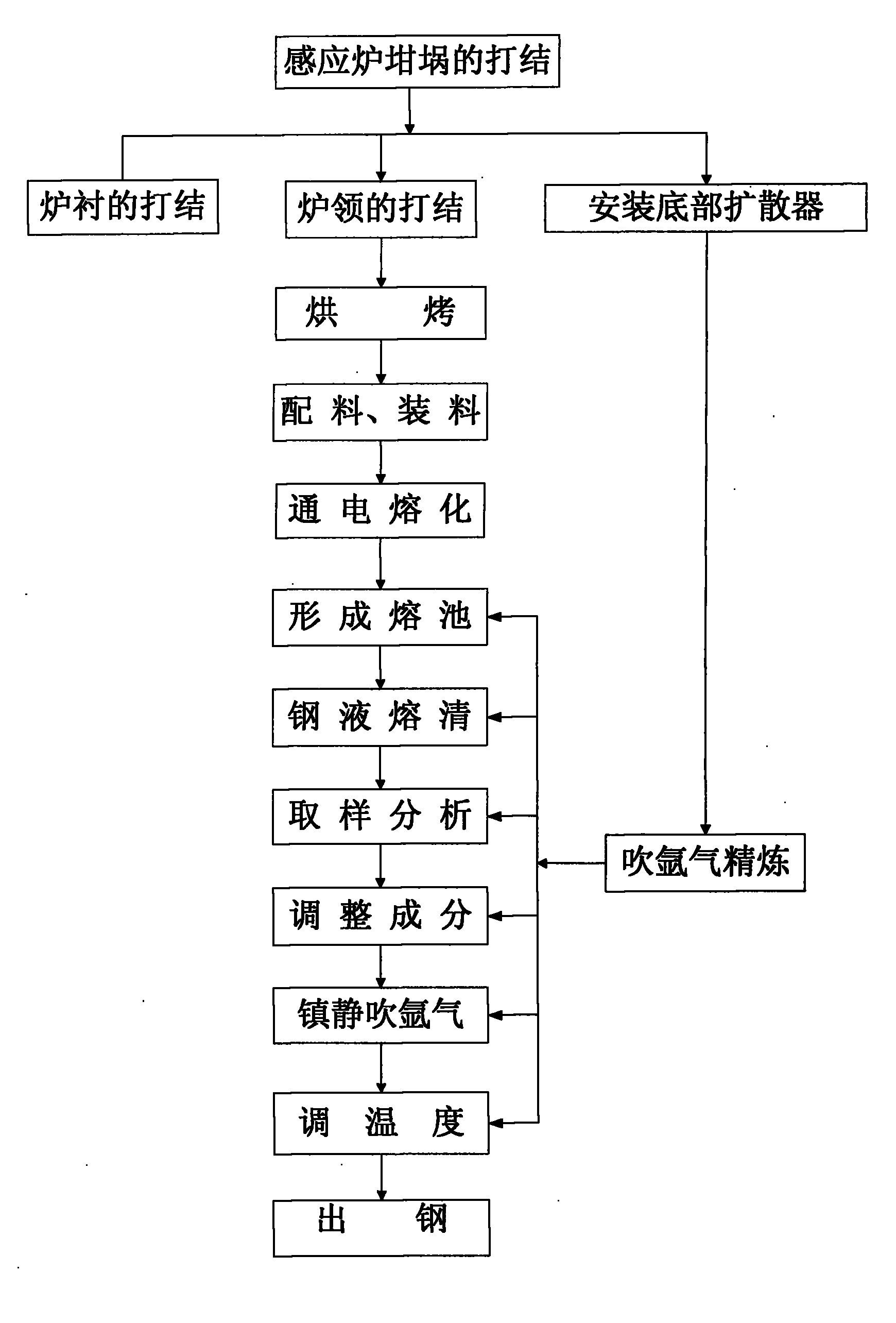

[0034] refer to figure 1 , 2 , the intermediate frequency induction furnace blowing argon in the furnace is composed of a furnace cover 1, a furnace lining 2, a crucible 3, a gas diffuser 6, a packing 7 and a joint 8, the slag 4 and molten steel 5 in the crucible 3, the argon blowing system It is composed of argon cylinder 10, pressure reducing valve 11, flow regulator 12 and pressure-resistant rubber tube 9. The refining process is:

[0035] 1. Knotting the crucible, knotting the lower crucible and the upper furnace collar with furnace lining material and furnace neck material respectively, and installing a gas diffuser at the bottom of the furnace and drying it;

[0036] 2. Batching and loading: According to the chemical composition requirements of manganese steel, calculate the ingredients and lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com