Alloyed spherical powder preparation device and method for laser 3D (three-dimensional) printing

A technology of alloy powder and 3D printing, which is applied in metal processing equipment, transportation and packaging, additive processing, etc., and can solve the problems of high consumption of inert gas, large human influence factors, and low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

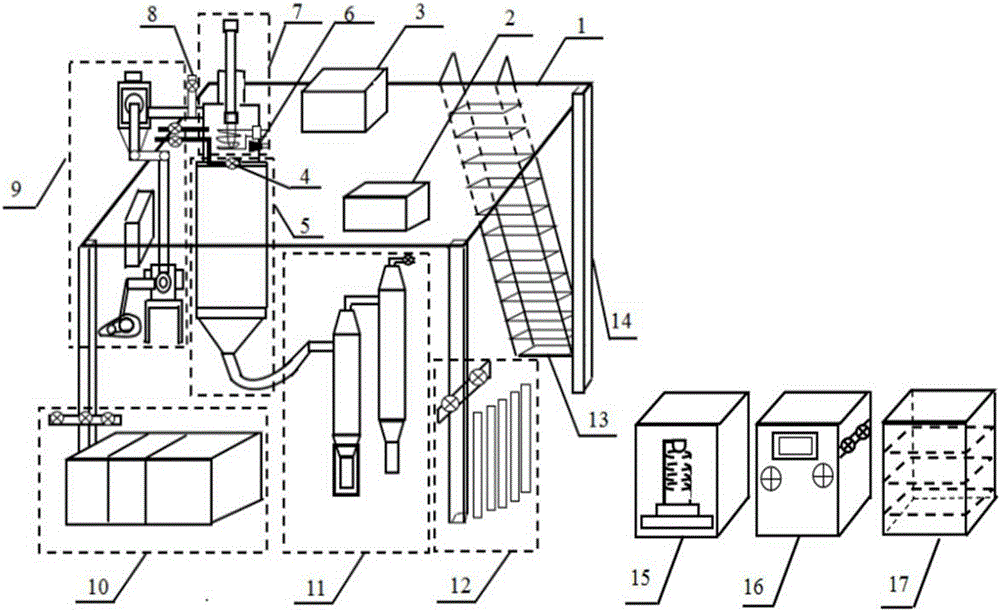

[0086] A high-performance spherical alloy powder preparation device for laser 3D printing, such as figure 1 As shown, the composition includes vacuum acquisition and inflation system, induction melting system, atomization powder making system, powder collection system, power supply system, electric control system, automatic induction temperature measurement system, atomization nozzle pressure automatic control system, vacuum sieve powder With storage tank system, automatic water cooling circulation system and safety protection system;

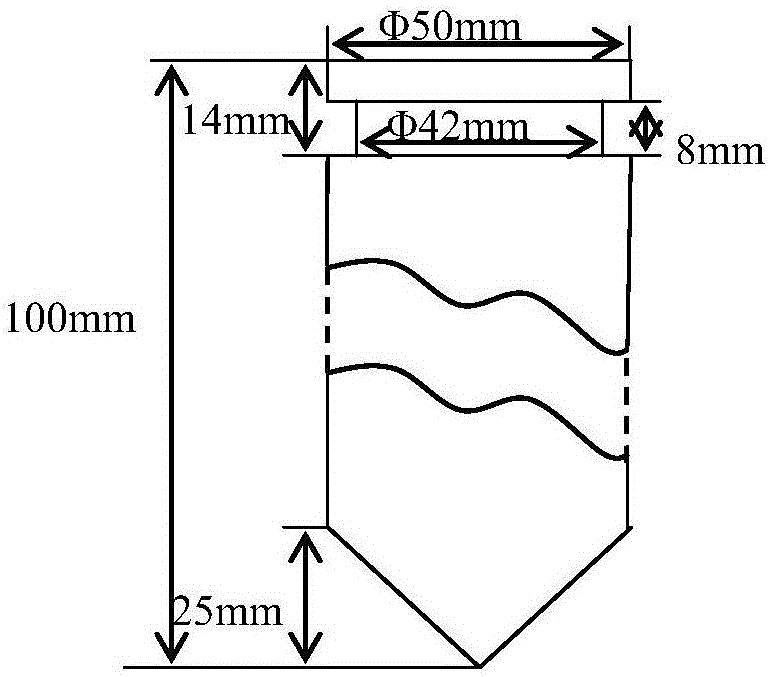

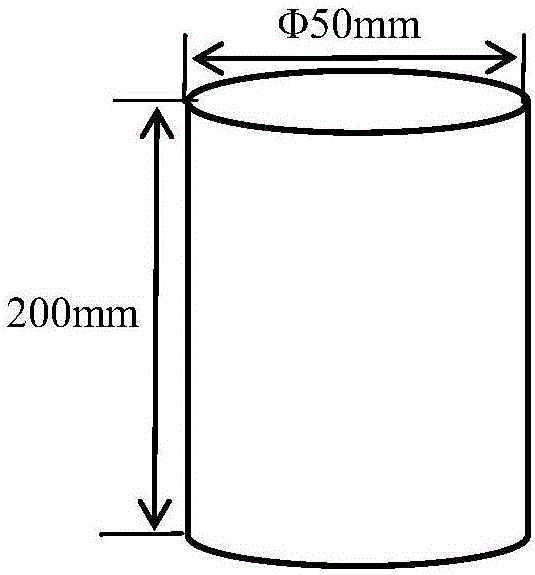

[0087] The described induction melting system adopts EIGA induction melting, and the principle diagram of induction melting is as shown in Figure 4 As shown, it includes an induction coil without a crucible, a continuous feeder, and a melting chamber. The continuous feeder has the function of downward movement and autotransmission. The continuous feeder is set in the upper part of the melting chamber, and the crucible-free induction coil is set ins...

Embodiment 2

[0134] High-performance spherical alloy powder preparation device for laser 3D printing, such as figure 1 As shown, the difference from Example 1 is: (1) VIGA induction melting is used, and the principle diagram of induction melting is as follows Figure 5 As shown, the induction smelting system uses induction coils with crucibles, specifically two sets of ceramic crucibles; two sets of magnesium oxide crucibles (one set for 20 kg and one set for 10 kg); one set of electric induction electrode feed mechanism and plug mechanism drive; A set of plug rod components; (2) Automatic induction temperature measurement system, including a set of tungsten rhenium thermocouple temperature measurement mechanism;

[0135] Using the above-mentioned high-performance spherical alloy powder preparation device for laser 3D printing, the method for preparing high-performance spherical 24CrNiMoRe alloy powder for laser 3D printing specifically includes the following steps:

[0136] Step 1. Selection of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com