Opal glass suitable for full electrofusion forming and preparation process thereof

A milky white glass and preparation technology, applied in the direction of electric furnace, furnace type, furnace, etc., can solve the problems of many product defects, strong corrosion of glass, etc., and achieve the effects of green production, uniform chemical composition, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation process of the invention is as follows: raw material crushing-mixing-full electric melting-molding. First of all, after the raw materials are selected and washed, they are coarsely and mediumly crushed by jaw crusher, hammer crusher or impact crusher, and finely crushed by ball mill. ~100 meshes; then, crush the base material, auxiliary materials and additives and weigh them accurately according to the requirements, then mix them in the mixer, and the uniformity should reach more than 98%;

[0018] Secondly, use all-electric melting to prepare milky white glass at a temperature of 1480-1520°C, and evenly spread a thin layer of uniformly mixed batch material on the glass liquid surface in a 10-square-meter all-electric melting furnace to make the entire batch material fully Melting, homogenizing and refining are carried out to ensure that the glass melts uniformly and without bubbles. Adjust its thickness according to the condition of the cold material l...

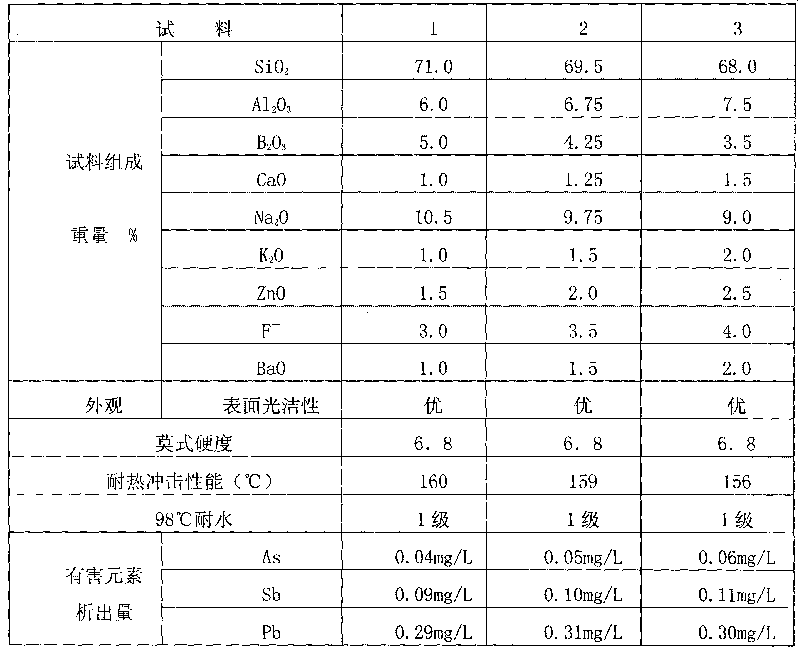

example 1

[0021] Example 1 uses material side 1 test, and each composition is as follows: SiO 2 71.0%, Al 2 o 3 6.0%, B 2 o 3 5%, CaO 1.0%, Na 2 O 10.5%, K 2 O 1.0%, ZnO 1.5%, F- 3.0%, BaO 1.0%, each ingredient is crushed to 60 mesh and mixed, the batch is mixed evenly, and then put into an electric furnace to heat and melt, the maximum temperature of the furnace is 1480°C, each group in the batch Parts are fully melted, homogenized and clarified. Then it was taken out for blow molding, and its appearance and physical and chemical properties were evaluated.

example 2

[0022] Example 2 uses material side 2 test, and each composition is as follows: SiO 2 69.5%, Al 2 o 3 6.75%, B 2 o 3 4.25%, CaO 1.25%, Na 2 O 9.75%, K 2 O 1.5%, ZnO 2.0%, F - 3.5%, BaO 1.5%, each ingredient is crushed to 80 mesh and mixed, the batch is evenly mixed, and then put into an electric furnace to heat and melt. The samples were taken out and blown into molds, and their appearance and physical and chemical properties were evaluated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com