Multi-layer double-channel electric arc additive manufacturing method for aluminum alloy structural component

A technology for additive manufacturing and structural parts, applied in the field of multi-layer double arc additive manufacturing of aluminum alloy structural parts, can solve the problems of low utilization rate of materials, cumbersome procedures, difficult processing, etc., and achieves good metallurgical bonding performance, chemical The effect of uniform composition and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

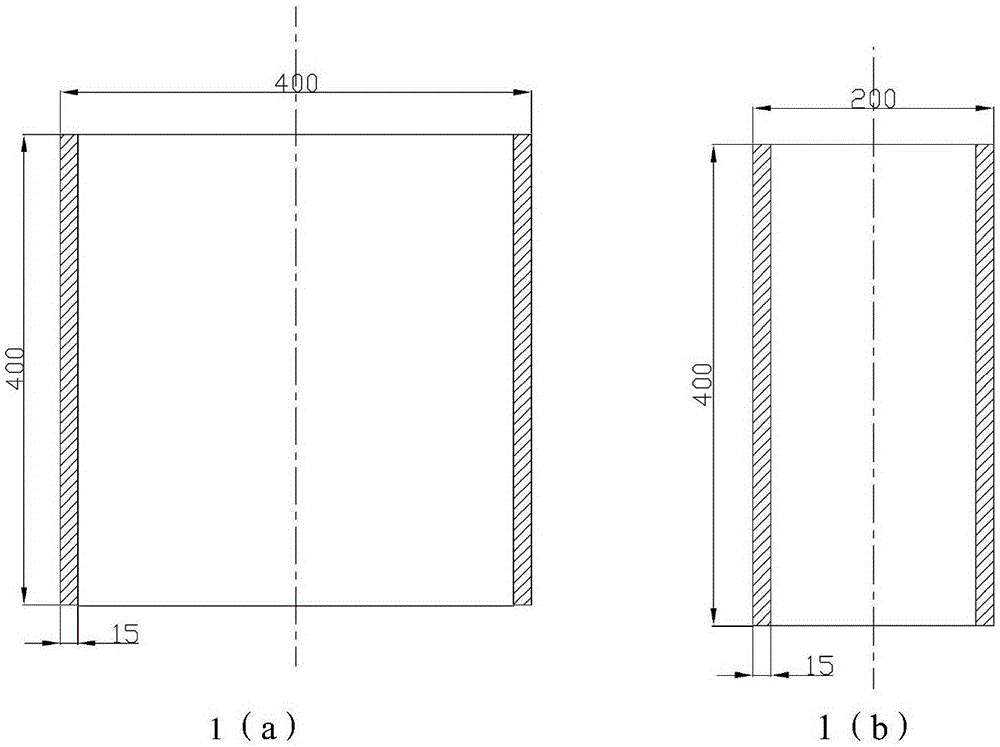

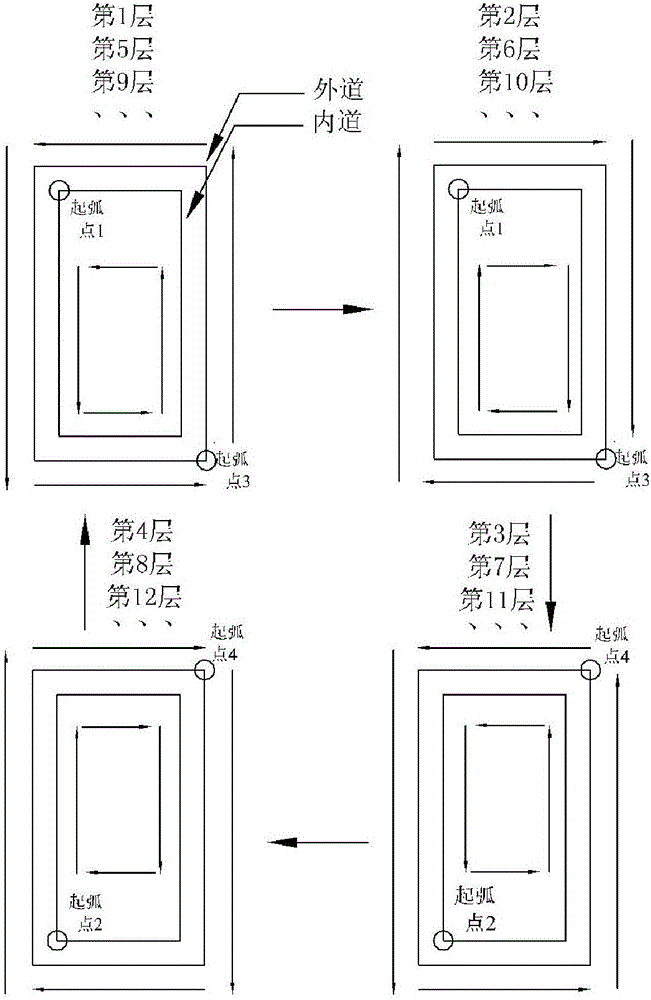

[0021] Example: 15mm thick 5B06 aluminum alloy rectangular structural parts multi-layer double-channel arc additive manufacturing

[0022] The specific implementation method is as follows: figure 1 As shown, the wall thickness of the aluminum alloy structural parts required to be manufactured is 15mm, and the length, width and height are 400mm, 200mm and 400mm respectively, and multi-layer double-channel arc additive forming is considered. The raw material used is ф1.2mm 5B06 aluminum alloy welding wire. First, a set of suitable forming process parameters was obtained through experiments: welding current 120A, wire feeding speed 7m / min, welding speed 8mm / s. Under this set of process parameters, single pass The width of the weld seam is 8mm, the height is 1.3mm, and the offset of the welding torch is 5mm, which can ensure the fusion between the passes and the overall formation; the pickled substrate is polished and wiped clean with absolute ethanol or acetone, and then fixed on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com