Vacuum oil filling and detecting system for transformer

A detection system and technology for transformers, which are used in transformer/inductor cooling, liquid/vacuum measurement for liquid tightness, etc., can solve problems such as unbalanced internal and external pressures of bellows, tensile deformation of bellows, etc., and are easy to popularize. and the effect of circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

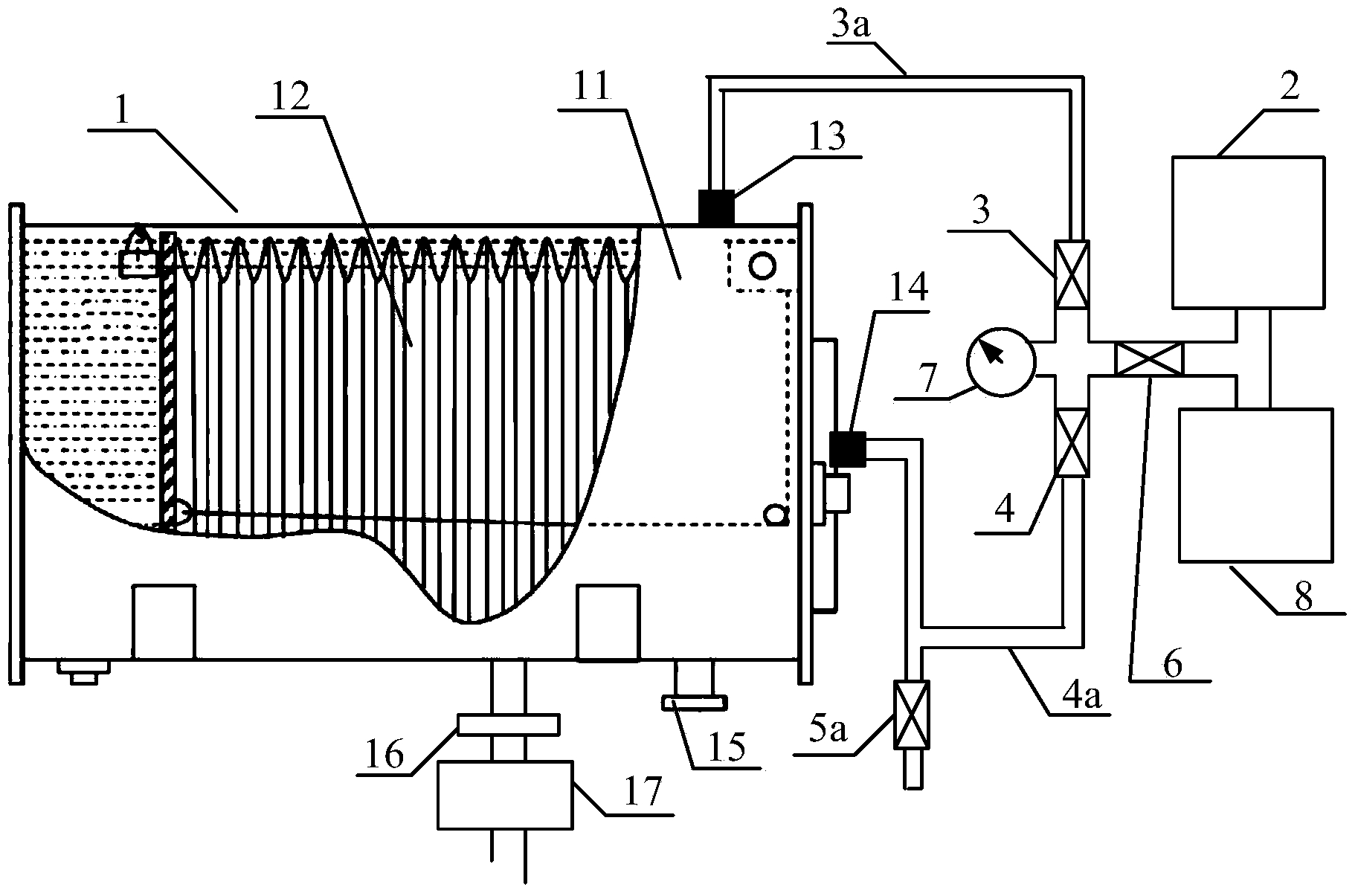

[0042] This embodiment provides a transformer vacuum oil filling and detection system, such as figure 1 , figure 2 , image 3 As shown, it includes a corrugated oil conservator 1 and a vacuum device 2 .

[0043] The chamber between the oil conservator shell 11 and the bellows 12 of the corrugated oil conservator 1 communicates with the exhaust port 13 ; the inner cavity of the bellows 12 communicates with the breathing port 14 .

[0044] The exhaust port 13 is in sealing communication with the vacuum device 2 through the first connecting pipe 3a; the exhaust port vacuum valve 3 is arranged on the first connecting pipe 3a, and the exhaust port vacuum valve 3 control whether the chamber between the oil conservator shell 11 and the bellows 12 communicates with the vacuum device 2 .

[0045] The breathing port 14 is in sealing communication with the vacuum device 2 through the second connecting pipe 4a; the breathing port vacuum valve 4 is arranged on the second connecting pip...

Embodiment 2

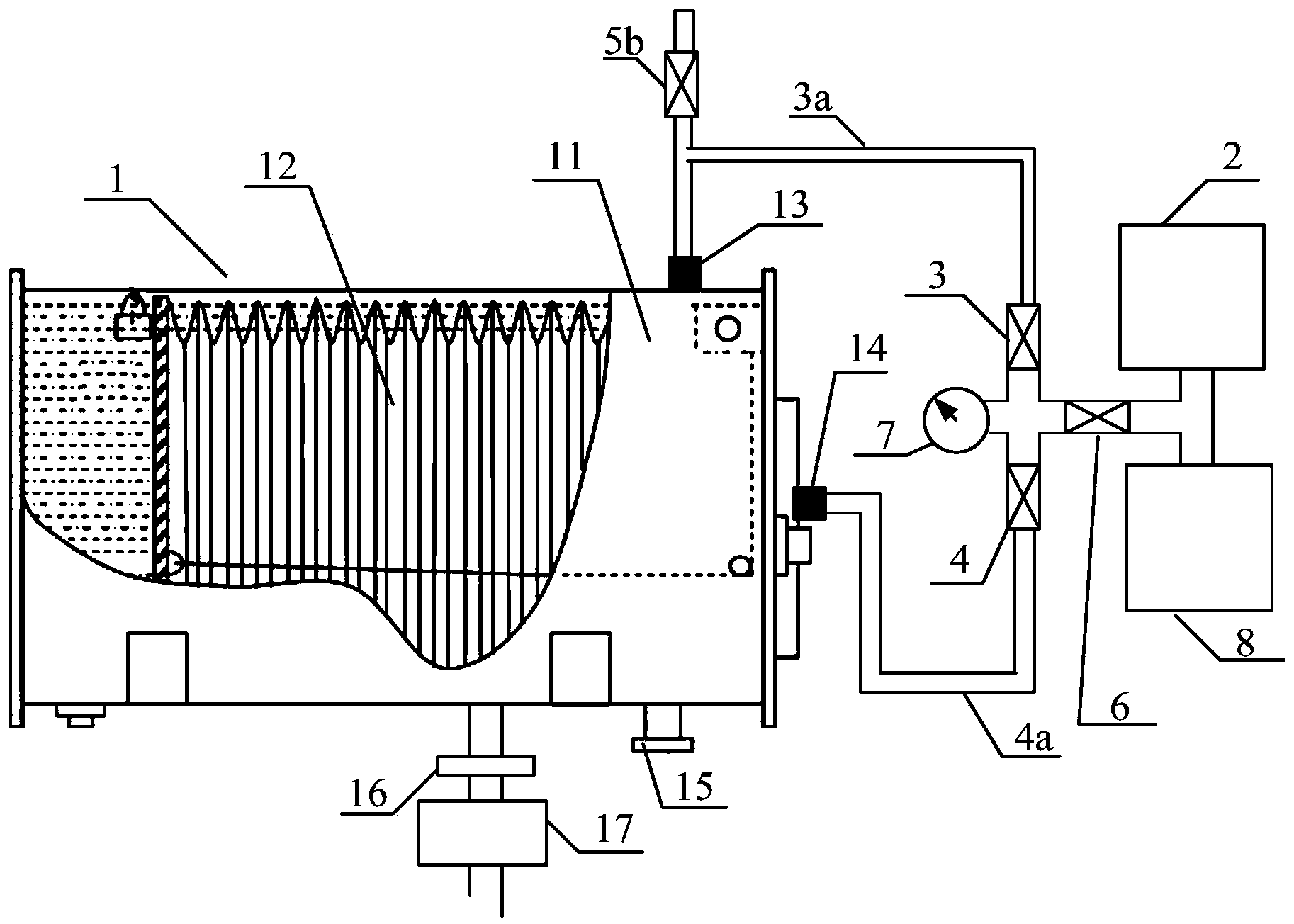

[0059] On the basis of Embodiment 1, the transformer vacuum oil filling and detection system described in this embodiment, such as figure 1 , figure 2 , image 3 shown, also includes:

[0060] The main valve 6, one end of which is in sealing communication with the vacuum device 2, and the other end is in sealing communication with the exhaust port vacuum valve 3 and the breathing port vacuum valve 4 respectively, through the opening and closing of the main valve 6 Control whether the exhaust port vacuum valve 3 and the breathing port vacuum valve 4 communicate with the vacuum device 2 .

[0061] By setting the main valve 6, it can work together with the vacuum valve 3 at the exhaust port to prevent the transformer oil from entering the vacuum device 2 from the first connecting pipe 3a during vacuum oil filling, causing damage to the vacuum device 2, and realizing double insurance control .

[0062] As a preferred implementation, the transformer vacuum oiling and detection...

Embodiment 3

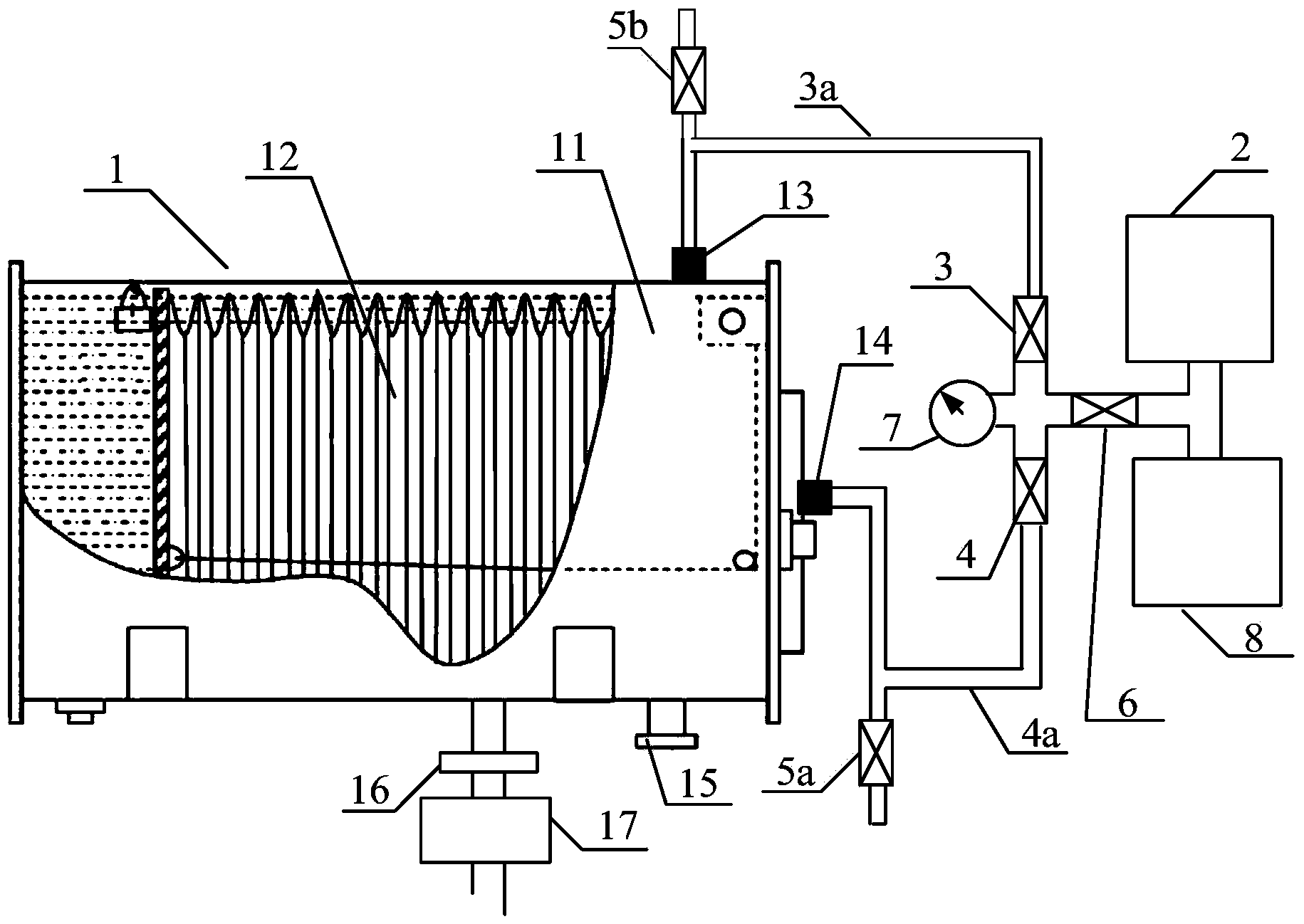

[0068] On the basis of Embodiment 1 or Embodiment 2, the transformer vacuum oiling and detection system described in this embodiment, such as figure 1 , figure 2 , image 3 shown, also includes:

[0069] The inflation device 8 is in sealing communication with the main valve 6 .

[0070] The inflation device 8 can be an air pump.

[0071] As an optional implementation mode, in the transformer vacuum oiling and detection system described in this embodiment, the main valve 6, the vacuum device 2 and the inflation device 8 are in sealed communication through a three-way pipe joint.

[0072] When the vacuum oiling operation is finished, close the exhaust port vacuum valve 3, the regulating valve and the vacuum device 2, and open the breathing port vacuum valve 4 and the main valve 6, because the inflation device 8 is sealed with the main valve 6 through the three-way pipe joint Therefore, the inflatable device 8 is opened, and air pressure can be added to the inner cavity of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com