Method for forming functional graded part through selective laser melting

A technology of selective laser melting and functional gradient, applied in metal material coating process, coating and other directions, can solve the problems of complex forming process, and achieve the effect of reducing production cost, saving total forming time, and reducing the number of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

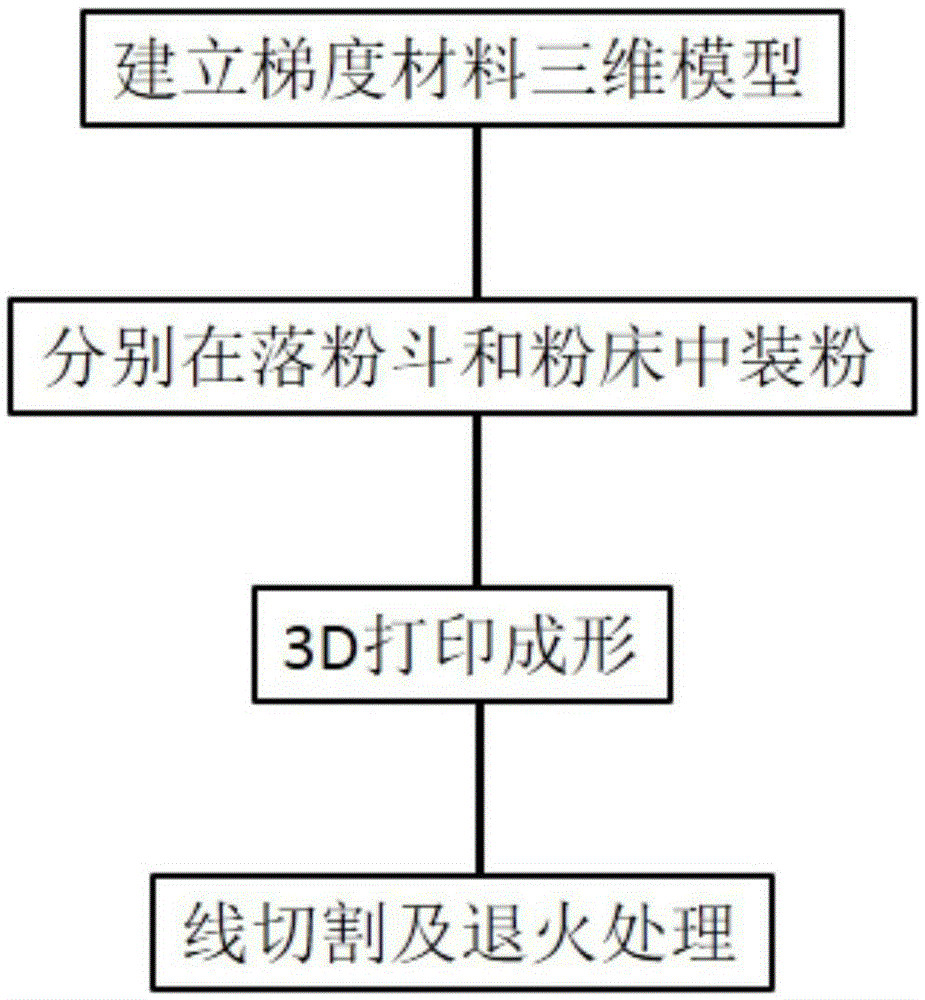

[0022] A method for forming functionally graded parts by using selective laser melting forming technology, comprising the following steps:

[0023] (1) Establish a three-dimensional model of the functionally graded part on the computer, then convert the three-dimensional model of the part into STL format and import it into the laser melting forming equipment for selected areas;

[0024] (2) Place the 316L stainless steel powder in the powder bed of the equipment, and place the Inconel718 powder suitable for selective laser melting into the powder feeding hopper of the equipment; among them, both the 316L stainless steel powder and the Inconel718 powder are spherical or nearly spherical, with an average The particle size is 30μm and the oxygen content is lower than 1000ppm;

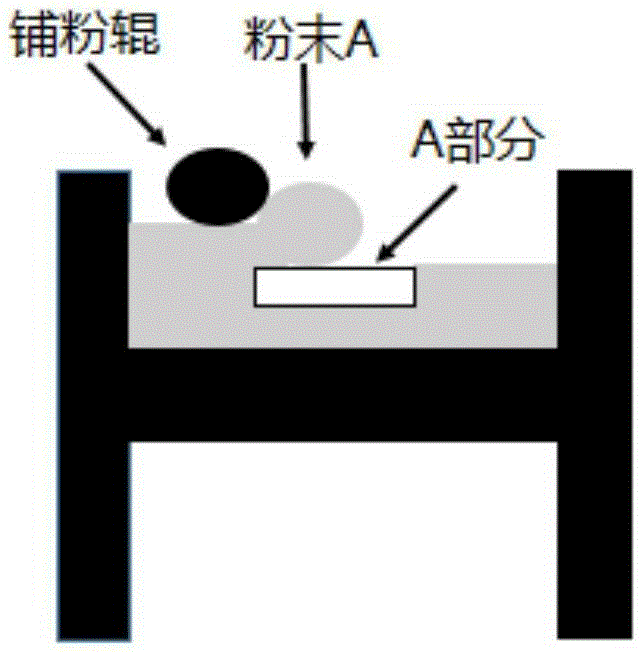

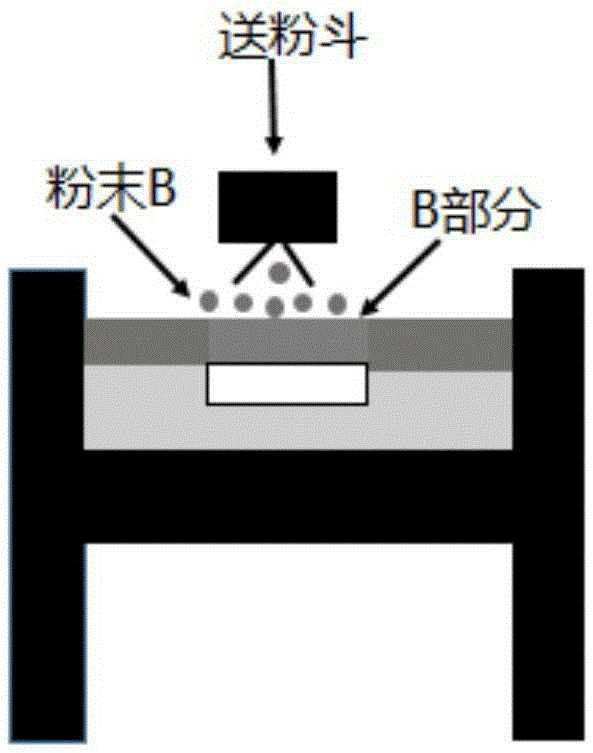

[0025] (3) Start the selected area laser melting forming equipment, use the powder feeding cylinder and powder spreading roller to spread a layer of 316L stainless steel powder on the powder bed, the laser...

Embodiment 2

[0028] A method for forming functionally graded parts by using selective laser melting forming technology, comprising the following steps:

[0029] (1) Establish a three-dimensional model of the functionally graded part on the computer, then convert the three-dimensional model of the part into STL format and import it into the laser melting forming equipment for selected areas;

[0030] (2) Place the 316L stainless steel powder in the powder bed of the equipment, and place the Inconel718 powder suitable for selective laser melting into the powder feeding hopper of the equipment;

[0031] Among them, 316L stainless steel powder and Inconel718 powder are both spherical or nearly spherical, with an average particle size of 37.5 μm and an oxygen content of less than 1000 ppm;

[0032] (3) Start the selected area laser melting forming equipment, use the powder feeding cylinder and powder spreading roller to spread a layer of 316L stainless steel powder on the powder bed, the laser ...

Embodiment 3

[0035] A method for forming functionally graded parts by using selective laser melting forming technology, comprising the following steps:

[0036] (1) Establish a three-dimensional model of the functionally graded part on the computer, then convert the three-dimensional model of the part into STL format and import it into the laser melting forming equipment for selected areas;

[0037] (2) Place the 316L stainless steel powder in the powder bed of the equipment, and place the Inconel718 powder suitable for selective laser melting into the powder feeding hopper of the equipment;

[0038] Among them, 316L stainless steel powder and Inconel718 powder are both spherical or nearly spherical, with an average particle size of 45 μm and an oxygen content of less than 1000 ppm;

[0039] (3) Start the selected area laser melting forming equipment, use the powder feeding cylinder and powder spreading roller to spread a layer of 316L stainless steel powder on the powder bed, the laser so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com