Environmental-friendly energy-saving blast-furnace oxygen ironmaking method

An environmental protection, energy saving, blast furnace technology, applied in the field of ironmaking, can solve the problems of energy waste, large investment, high maintenance cost, etc., and achieve the effects of reducing production costs, improving economic benefits, and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

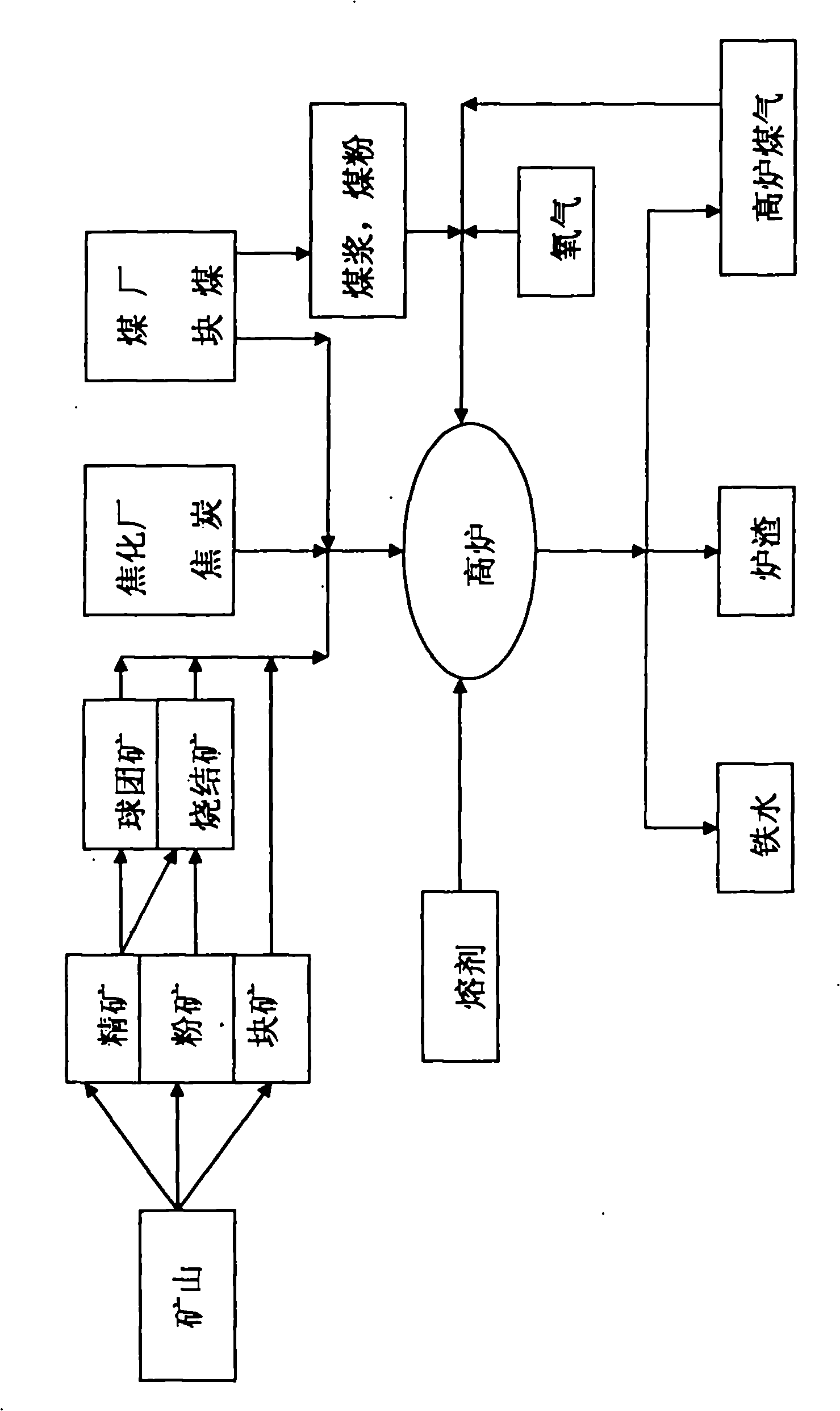

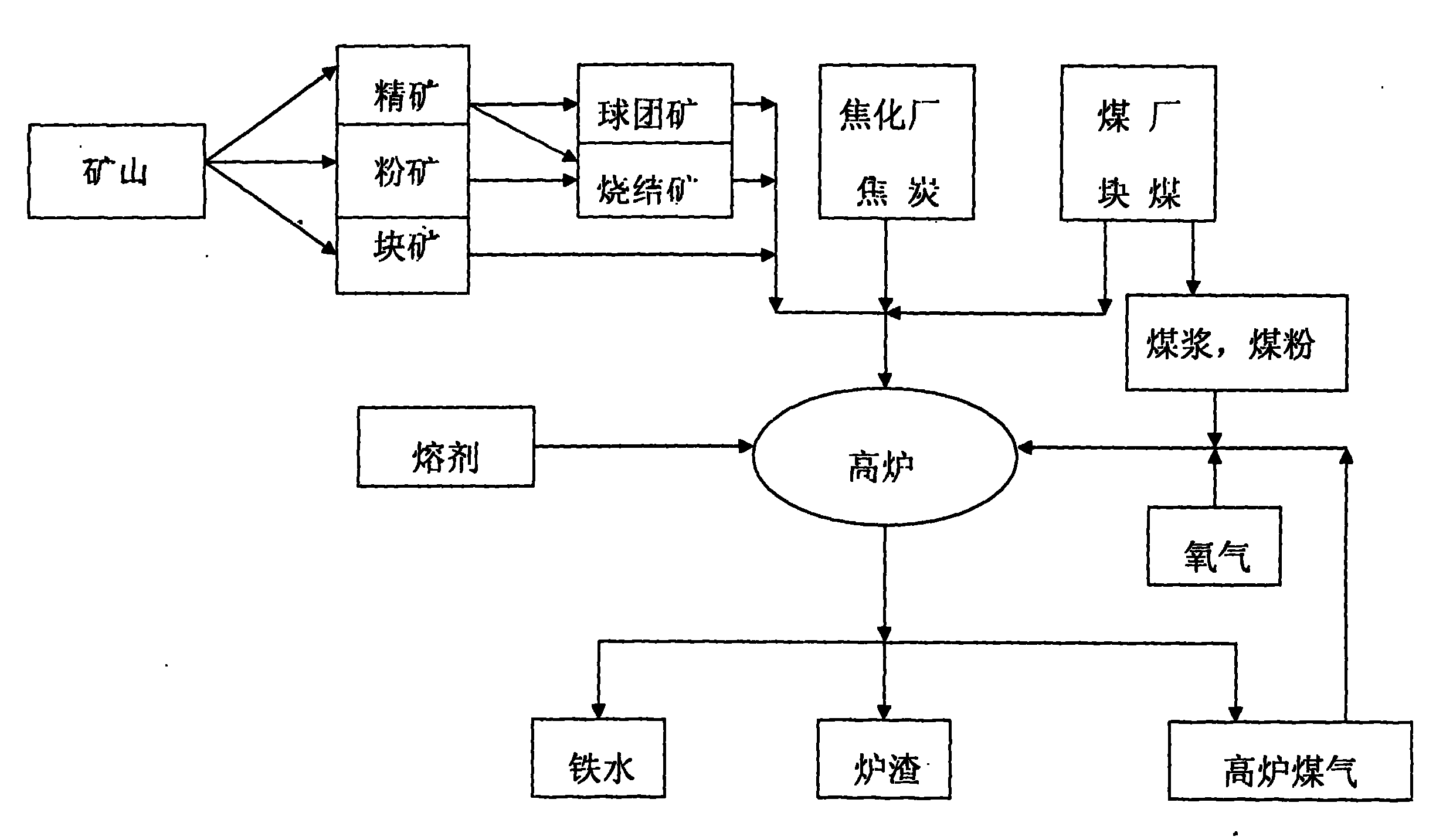

[0007] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0008] With reference to accompanying drawing, the present invention is to adopt blast furnace and the charging device connected with it, and the smelting equipment that is connected with blast furnace air inlet and blast furnace gas pipeline to form and carry out ironmaking. Its production method is: put iron ore, coal, coke and flux weighed according to the specified amount into the blast furnace through the feeding device from the feed inlet of the blast furnace roof, and at the same time, feed oxygen from the air inlet at the lower part of the blast furnace through the oxygen pipeline. It is blown into the blast furnace to make oxygen chemically react with the coal and coke in the blast furnace to generate CO and H 2 The high-temperature combustible gas is used as a high-temperature reducing agent, and the heat released during the chemical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com