System and process for preparing cyclic carbonate by using composite ionic liquid catalyst

A liquid catalyst, cyclic carbonate technology, applied in the field of circulation process and circulation system, can solve the problems of poor purity, inability to achieve large-scale production, high cost, and achieve the effect of stable process and high recyclability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0112] Propylene Carbonate Synthesis

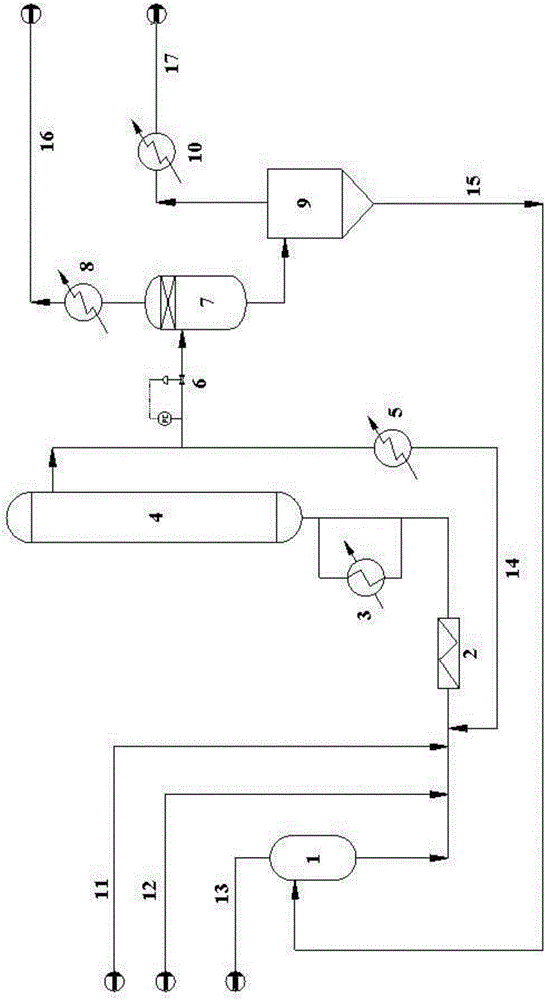

[0113] according to figure 1 In the process system shown, the specification of the pipeline mixer is DN100×1000mm, and the specification of the straight-tube tubular reactor is Φ450×20000mm. The reactor adopts the operation method of material feeding in and out at the bottom, and the filler is made of 16*16*0.3 metal stainless steel Baoer ring packing.

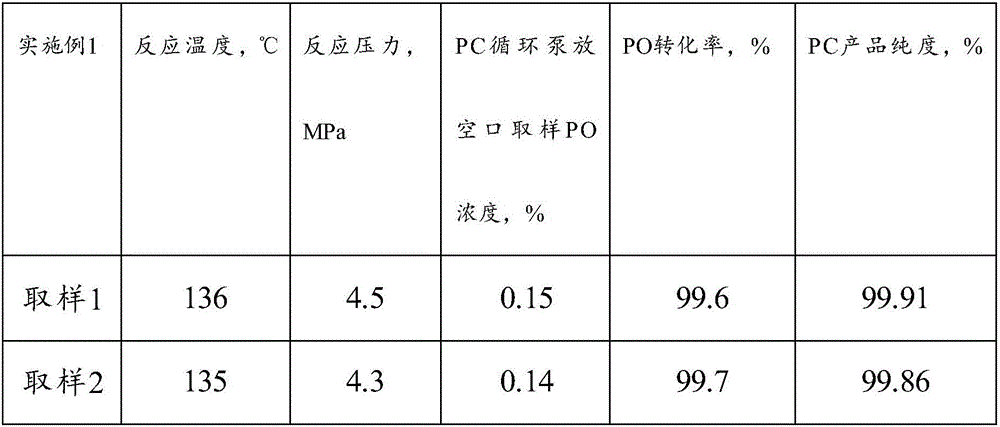

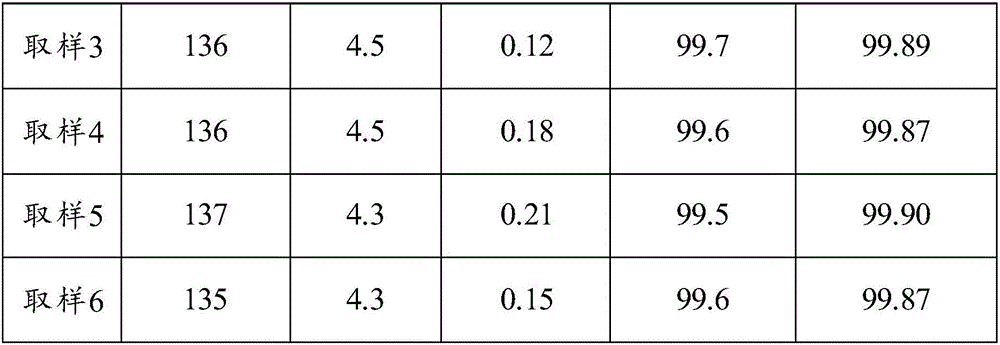

[0114] First inject the propylene carbonate solution containing 50kg composite ionic liquid catalyst in the circulating catalyst tank, complete the system filling with propylene carbonate and composite ionic liquid catalyst according to the process steps, start to feed the raw materials propylene oxide and carbon dioxide after heating up and boosting the pressure. The feed rate of oxypropane is 500kg / h, the feed rate of carbon dioxide is 416kg / h, the reaction temperature of the reactor is 135-140°C, and the reaction pressure is 4.0MPa. After the reaction, the material enters the flash ta...

Embodiment 2

[0120] Ethylene Carbonate Synthesis

[0121] according to figure 1 In the process method shown, the specification of the pipeline mixer is DN100×1000mm, and the specification of the straight pipe reactor is Φ400×18000mm. The reactor adopts the operation mode of material entering and exiting from the bottom, and the packing adopts 25*25*0.5 metal stainless steel Pall ring packing. Note that when this process is applied to the synthesis of ethylene carbonate, since the melting point of ethylene carbonate is 35-38°C, the entire system needs to be insulated and heat traced to prevent pipeline blockage during start-up and shutdown.

[0122] First inject the ethylene carbonate solution containing 38kg composite ionic liquid catalyst into the circulating catalyst tank, complete the system filling with ethylene carbonate and composite ionic liquid catalyst according to the process steps, start to feed the raw materials ethylene oxide and carbon dioxide after heating up and boosting t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com