Process for preparing titanium dioxide mesoporous nano-belt material by solvothermal method

A technology of titanium dioxide and solvothermal method, applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problems of toxicity and corrosion, potential safety hazards, irritation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

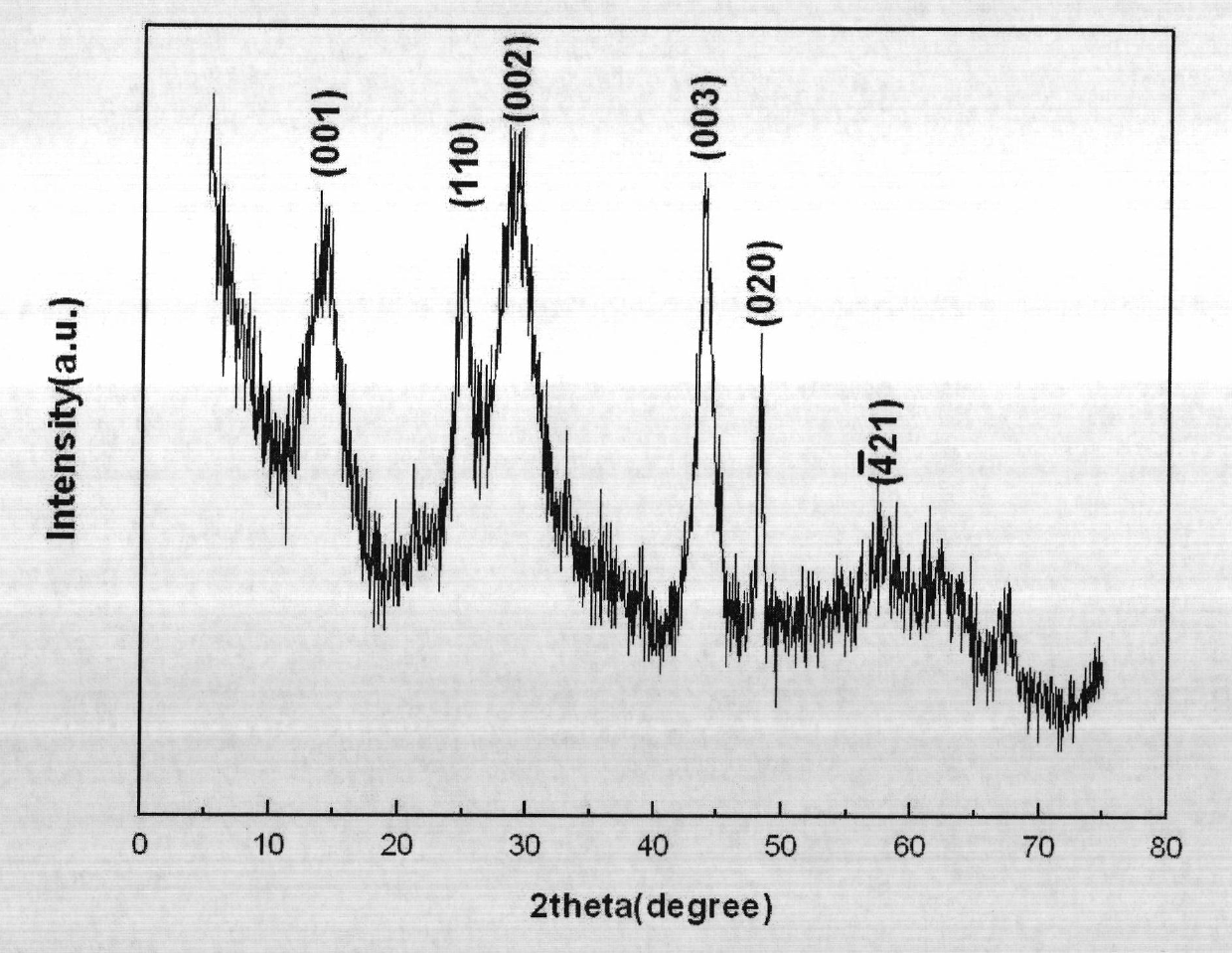

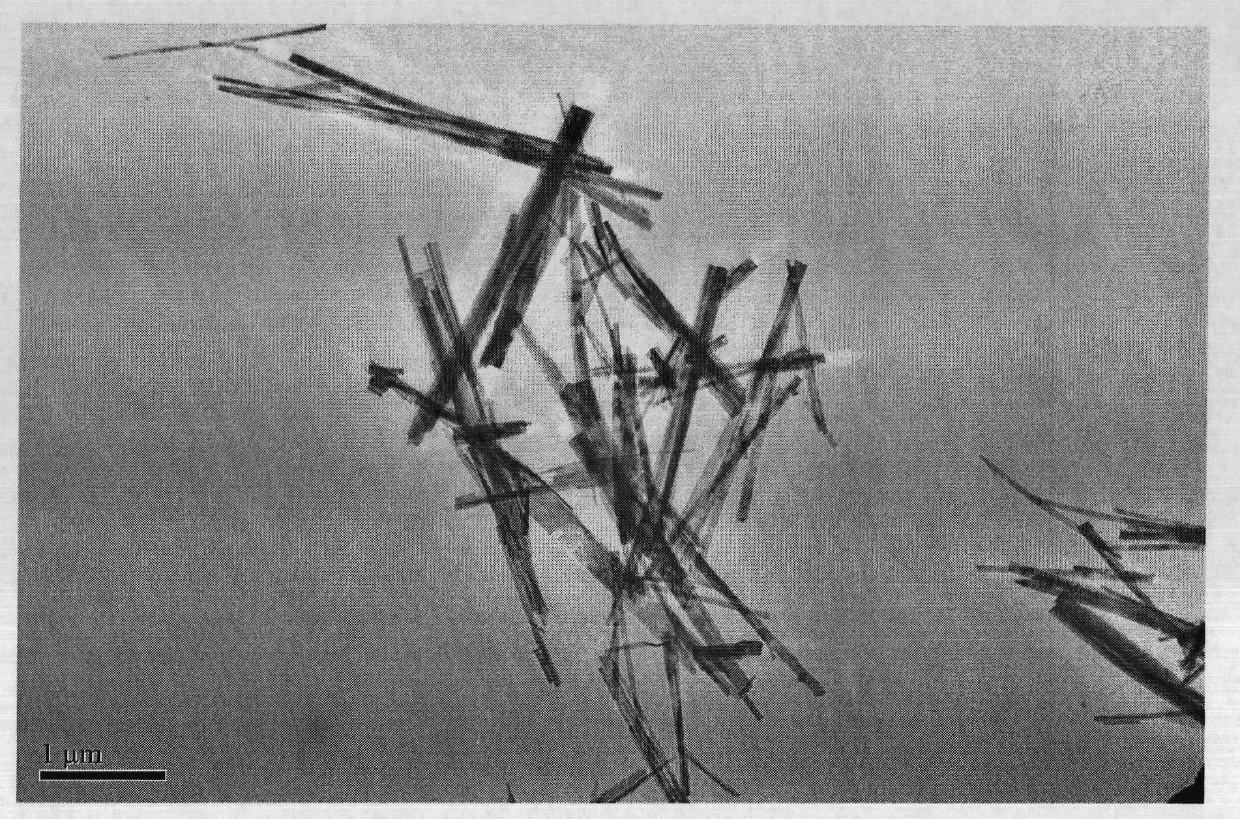

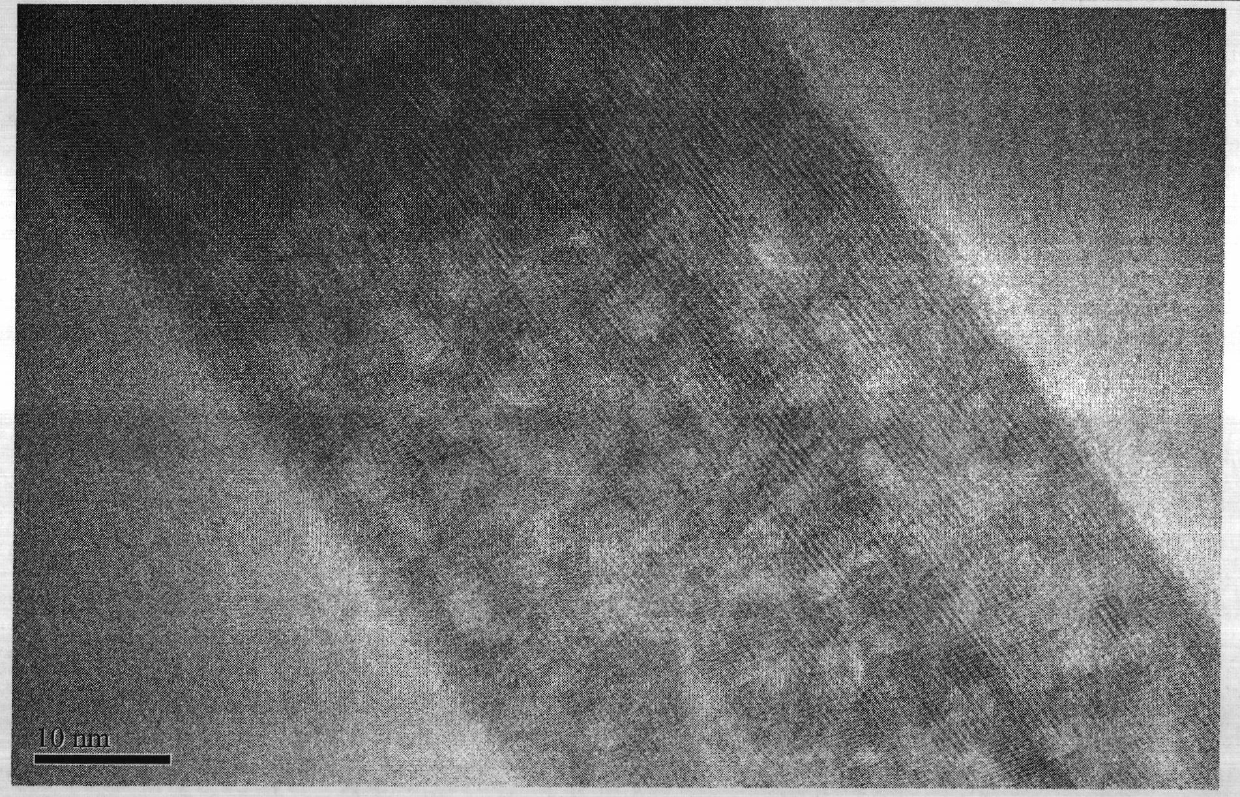

Image

Examples

Embodiment 1

[0020] 1. Accurately weigh the solid sodium hydroxide, configure it into a 10mol / L standard sodium hydroxide aqueous solution in a volumetric flask, and take 40mL into a beaker with a capacity of 100mL;

[0021] 2. Add 2g of titanium dioxide P25 powder to the beaker in step 1, stir for 5 minutes, then add an equal volume of absolute ethanol, and continue stirring for 5 minutes;

[0022] 3. Transfer all the suspension obtained in step 2 into the lining of a 100mL hydrothermal reactor, tighten the screws, and place the reactor in a thermostat at 180°C for 12 hours;

[0023] 4. After the temperature of the reaction kettle drops to room temperature, take out the lining, pour off the supernatant, and wash the solid sample with distilled water until the pH is 7;

[0024] 5. Add the solid sample obtained in step 4 to 0.1mol / L hydrochloric acid solution and continue stirring for 24 hours;

[0025] 6. Wash the sample in step 5 with distilled water to pH 7 by suction filtration, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com