Regeneration method for isodewaxing catalyst

A technology of isomerization dewaxing and catalyst, which is applied in the direction of catalyst regeneration/reactivation, molecular sieve catalysts, chemical instruments and methods, etc., and can solve the problems of unsuitable precious metal/molecular sieve lubricating oil isomerization dewaxing catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

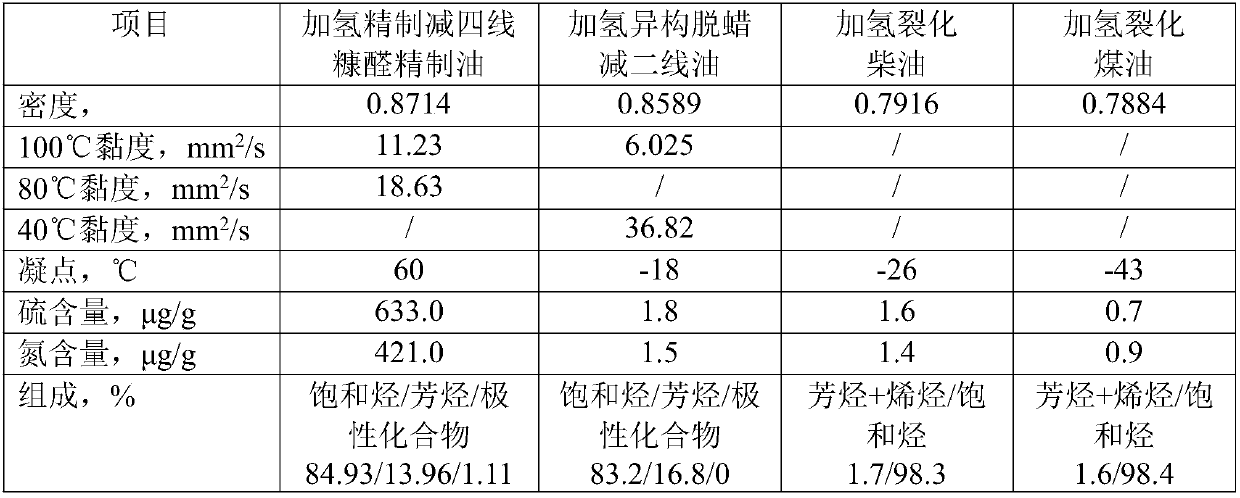

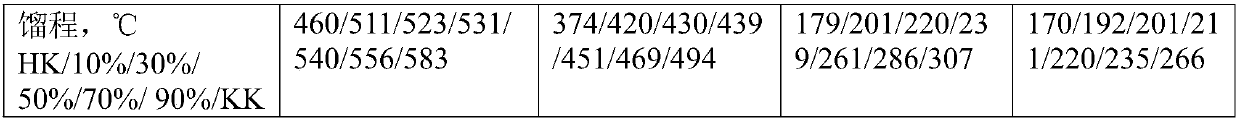

[0037] (1) Cleaning oil cleaning: select highly refined low pour point minus second line distillate oil with physical and chemical properties as shown in Table 1 as solvent carrier oil, that is, low pour point minus second line after hydrofining-isomerization dewaxing-supplementary refining Distillate oil, choose decahydronaphthalene as solvent. When the catalyst is online and the reaction temperature is 365°C, the system pressure is 12.0MPa, and the liquid hourly volume space velocity is 0.85h- 1 And hydrogen oil volume ratio 500Nm 3 / m 3 Under certain reaction conditions, the raw material oil is directly switched to solvent-carrying oil, the system pressure is reduced to 10.0MPa at a rate of 1.0MPa / h, and the hydrogen-oil volume ratio is adjusted to 1500Nm 3 / m 3 , and then mix decahydronaphthalene into the carrier oil according to the proportion of 10%, and maintain the state for 72h.

[0038] (2) Nitrogen purging: reduce the temperature of the catalyst bed to 280°C at ...

Embodiment 2

[0046] (1) Cleaning oil cleaning: the diesel distillate oil produced by the hydrocracking unit with physical and chemical properties as shown in Table 1 was selected as the solvent carrier oil, and tetrahydronaphthalene was selected as the solvent. When the catalyst is online and the reaction temperature is 365°C, the system pressure is 12.0MPa, and the liquid hourly volume space velocity is 0.85h- 1 And hydrogen oil volume ratio 500Nm 3 / m 3 Under the reaction process conditions, the raw material oil is directly switched to solvent carrying oil, the temperature is naturally lowered to 340°C, and the liquid hourly volume space velocity is adjusted to 2.0h- 1 , and then decahydronaphthalene is mixed into the solvent carrying oil according to the proportion of 20%, and the state is maintained for 24h.

[0047] (2) Nitrogen purging: reduce the temperature of the catalyst bed to 280°C at a rate of 10°C / h, stop feeding the cleaning oil, then reduce the system pressure to 1.6MPa a...

Embodiment 3

[0055] (1) Cleaning oil cleaning: select the kerosene distillate oil produced by the hydrocracking unit with physical and chemical properties as shown in Table 1 as the solvent carrier oil, and select tetrahydronaphthalene as the solvent. When the catalyst is online and the reaction temperature is 365°C, the system pressure is 8.0MPa, and the liquid hourly volume space velocity is 0.85h- 1 And hydrogen oil volume ratio 560Nm 3 / m 3 Under the reaction process conditions, first reduce the system pressure to 6.0MPa at a speed of 1.0MPa / h, then switch the raw oil to solvent-carrying oil, and adjust the liquid hourly volume space velocity to 1.0h- 1 , then raise the temperature of the catalyst bed to 380°C at a rate of 10°C / h, and adjust the hydrogen-oil ratio to 750Nm 3 / m 3 , the liquid hourly volume space velocity remains unchanged, and then decahydronaphthalene is mixed into the solvent carrying oil according to the proportion of 15%, and the state is maintained for 36 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com