Nano energy-containing material prepared by functional graphene and method thereof

A graphene and graphene oxide technology, applied in explosives and other directions, can solve the problems of high activity of nano aluminum layer, high equipment and poor stability, and achieve easy control of performance, increase reaction pressure, and improve structural order. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

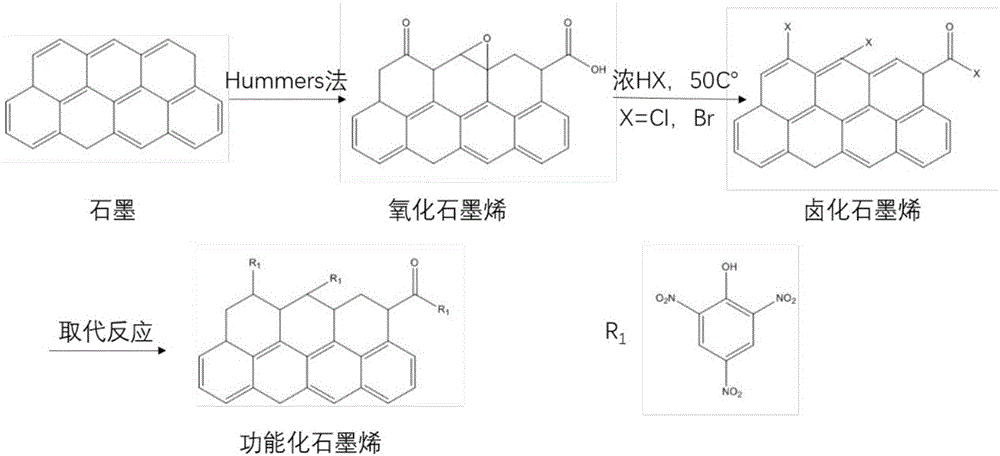

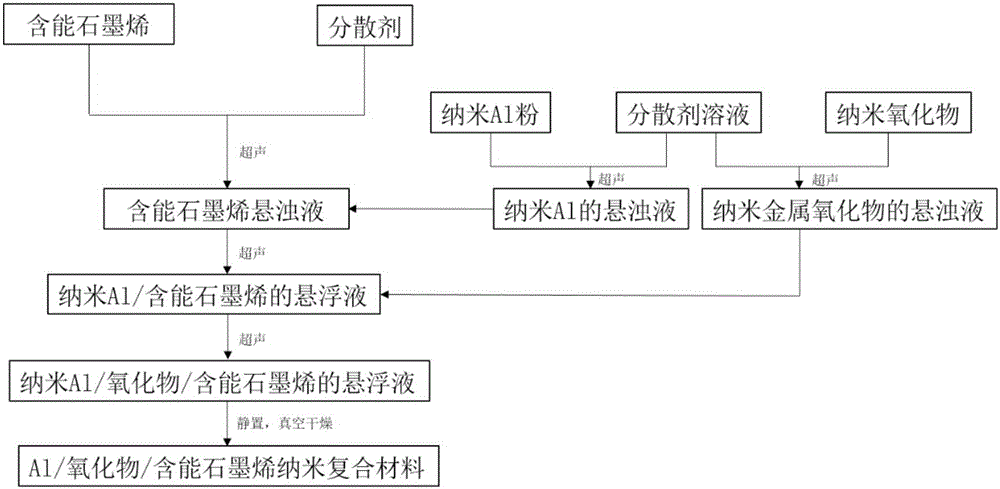

[0011] to combine figure 2 , the present invention utilizes functionalized graphene to prepare the preparation method of nano energy-containing material The specific steps are as follows:

[0012] Step 1: Prepare GO by the improved Hummers method, wash to neutral, and dry under vacuum;

[0013] Step 2, disperse the GO powder in deionized water, form a suspension after ultrasonication, add a halogenating agent, stir the reaction, and absorb the exhaust gas through the reflux device;

[0014] Step 3, diluting the reacted mixed solution in step 2 with deionized water, adding an alkaline solution, neutralizing the mixed solution to neutrality, and drying under vacuum conditions after suction filtration to obtain halogenated graphene;

[0015] Step 4, pouring the configured energetic compound solution into the reactor, adding the halogenated graphene prepared in step 3 into the mixed solution, keeping it warm, and obtaining the energetic graphene grafted with the energetic compou...

Embodiment 1

[0022] The present invention utilizes functionalized graphene to prepare the preparation method of nano energy-containing material. The specific steps are as follows:

[0023] Step 1: GO was prepared by the improved Hummers method, washed to neutral, and dried in vacuum at 50°C;

[0024] Step 2, disperse 0.2g GO powder in 50mL deionized water, form a suspension after ultrasonication for 3 hours, add 20mL halogenated agent concentrated HBr, stir and react at 60°C for 8 hours, and absorb exhaust gas through the reflux device;

[0025] Step 3, diluting the reacted mixed solution of step 2 with deionized water, adding a certain amount of NaOH solution, neutralizing the mixed solution to neutrality, and drying under vacuum conditions after suction filtration to obtain graphite halide;

[0026] Step 4, take 100mg 2,4,6-trinitrophenol, 30mg K 2 CO 3 and 10mL of N,N-dimethylformamide in a three-necked flask to prepare a mixed solution, add the halide graphite prepared in step 3 into...

Embodiment 2

[0032] The present invention utilizes functionalized graphene to prepare the preparation method of nano energy-containing material. The specific steps are as follows:

[0033] Step 1 to step 4 are the same as step 1 to step 4 in the example 1;

[0034] Step 5, disperse 20mg of energetic graphene in N,N-dimethylformamide, after ultrasonic dispersion, disperse 0.099mg of nano-Al particles in N,N-dimethylformamide and isopropanol solution in the mixed solution;

[0035] Step 6, disperse 0.281g of nano-NiO particles in the mixed solution of N,N-dimethylformamide and isopropanol solution, after ultrasonic dispersion, add the nano-Al particle suspension prepared in step 5, and continue ultrasonic dispersion 2 hours;

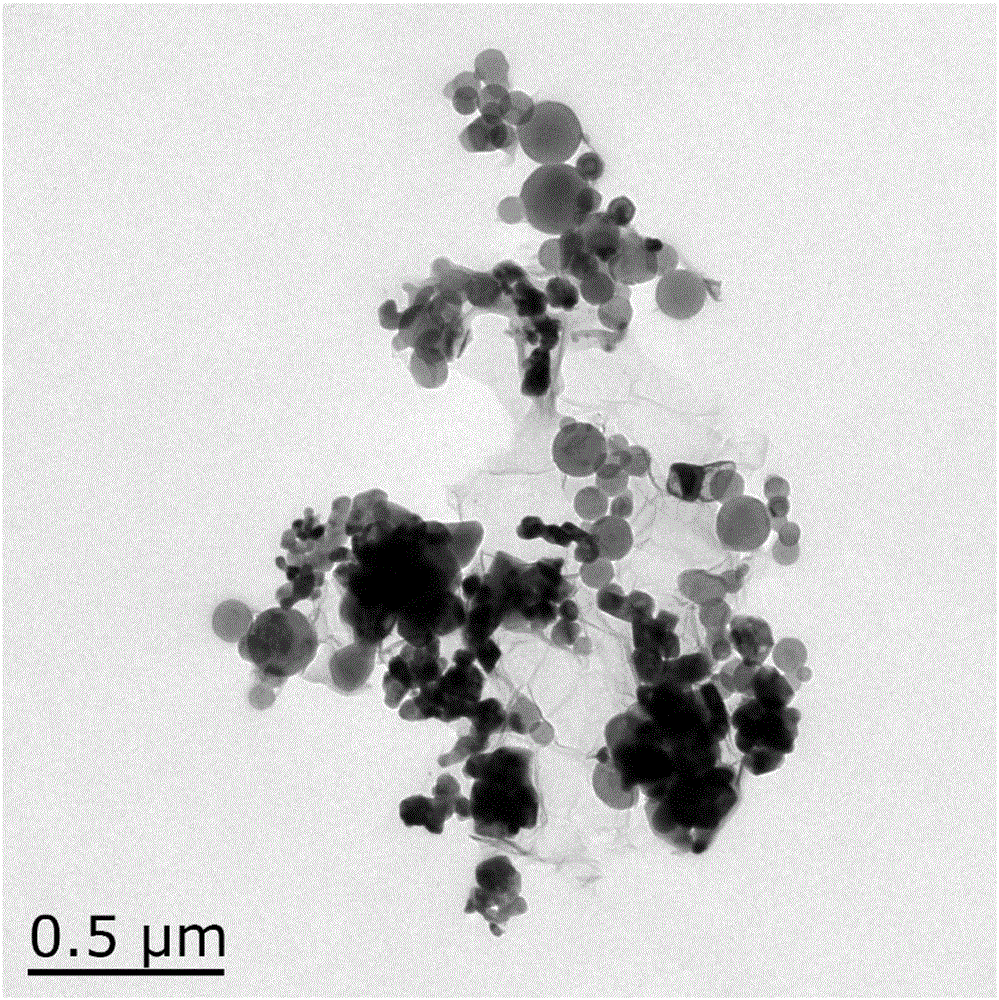

[0036] Step 7: After ultrasonication, let it stand still, absorb the clear night of the upper layer, and place it in a vacuum drying oven at 65° C. for 8 hours to obtain an energetic graphene / Al / NiO nanocomposite energetic material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com