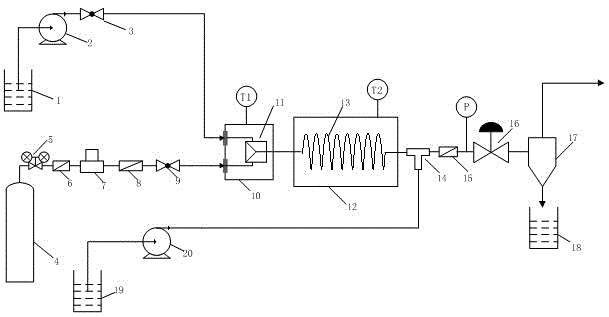

Cosynthesis device and method of cyclohexanol, cyclohexanone and adipic acid in microchannels

A synthesis device and technology for cyclohexanol, which are applied in chemical instruments and methods, preparation of carboxylic acids by oxidation, preparation of peroxy compounds, etc., can solve the problems of low selectivity between cyclohexanol and cyclohexanone, low conversion rate of cyclohexane, Environmental pollution and other problems, to achieve the effect of improving conversion rate and selectivity, shortening reaction time, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

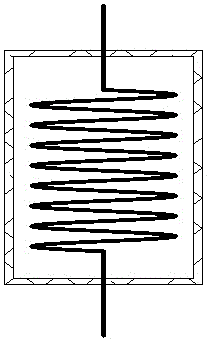

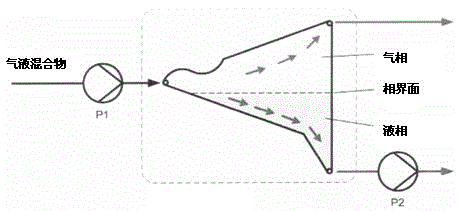

[0021] The reaction microtube is 35m in length and 0.508mm in inner diameter, rolled into a ring with a diameter of 20cm and placed in an air thermostat. The reaction temperature is 180°C, the pressure is 1.5MPa, the molar ratio of oxygen to cyclohexane is 0.3:1, the flow rate of cyclohexane is 0.79mL / min, the flow rate of the oxygen mass flow controller is set to 49.38mL / min, and the flow rate of isopropanol The flow rate is set to 0.8mL / min. After the reaction is stable, the cyclohexanol and cyclohexanone in the liquid phase product are analyzed by gas chromatography, the intermediate product cyclohexyl hydroperoxide is analyzed by iodine titration, and diacids such as adipic acid The by-products were analyzed by alkali titration. After inspection, the conversion rate of cyclohexane under this condition is 3.10%, the selectivity sum of cyclohexanol and cyclohexanone is 51.83%, the selectivity of cyclohexyl hydroperoxide is 30.17%, and the selectivity of adipic acid is 1...

Embodiment 2

[0023]The reaction microtube is 35m in length and 0.508mm in inner diameter, rolled into a ring with a diameter of 20cm and placed in an air thermostat. The reaction temperature is 200°C, the pressure is 8 MPa, the molar ratio of oxygen to cyclohexane is 0.15:1, the flow rate of cyclohexane is 2.36 mL / min, the flow rate of oxygen mass flow controller is 74.08 mL / min, and the flow rate of isopropanol is 1 mL / min. Under these conditions, the conversion rate of cyclohexane is 10.10%, the selectivity sum of cyclohexanol and cyclohexanone is 66.93%, the selectivity of cyclohexyl hydroperoxide is 8.78%, and the selectivity of adipic acid is 24.29% %.

Embodiment 3

[0025] For the cyclohexane oxidation reaction in the micro-reaction tube, the residence time is defined as the apparent residence time of cyclohexane at normal temperature, that is, the ratio of the volume of the empty tube to the volume flow rate of cyclohexane at normal temperature. The conversion rate of cyclohexane to cyclohexanol, cyclohexanone and adipic acid and the distribution of products are different under different residence times.

[0026] The residence time is 4 minutes: the reaction microtube is 35 m long and 0.508 mm in inner diameter, rolled into a ring with a diameter of 20 cm and placed in an air incubator. The reaction temperature is 180°C, the pressure is 1.5MPa, the molar ratio of oxygen to cyclohexane is 0.5:1, the flow rate of cyclohexane is 1.77mL / min, the flow rate of oxygen mass flow controller is set to 185.19mL / min, and the flow rate of isopropanol is 1mL / min. Under these conditions, the conversion rate of cyclohexane is 0.62%, the selectivity su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com