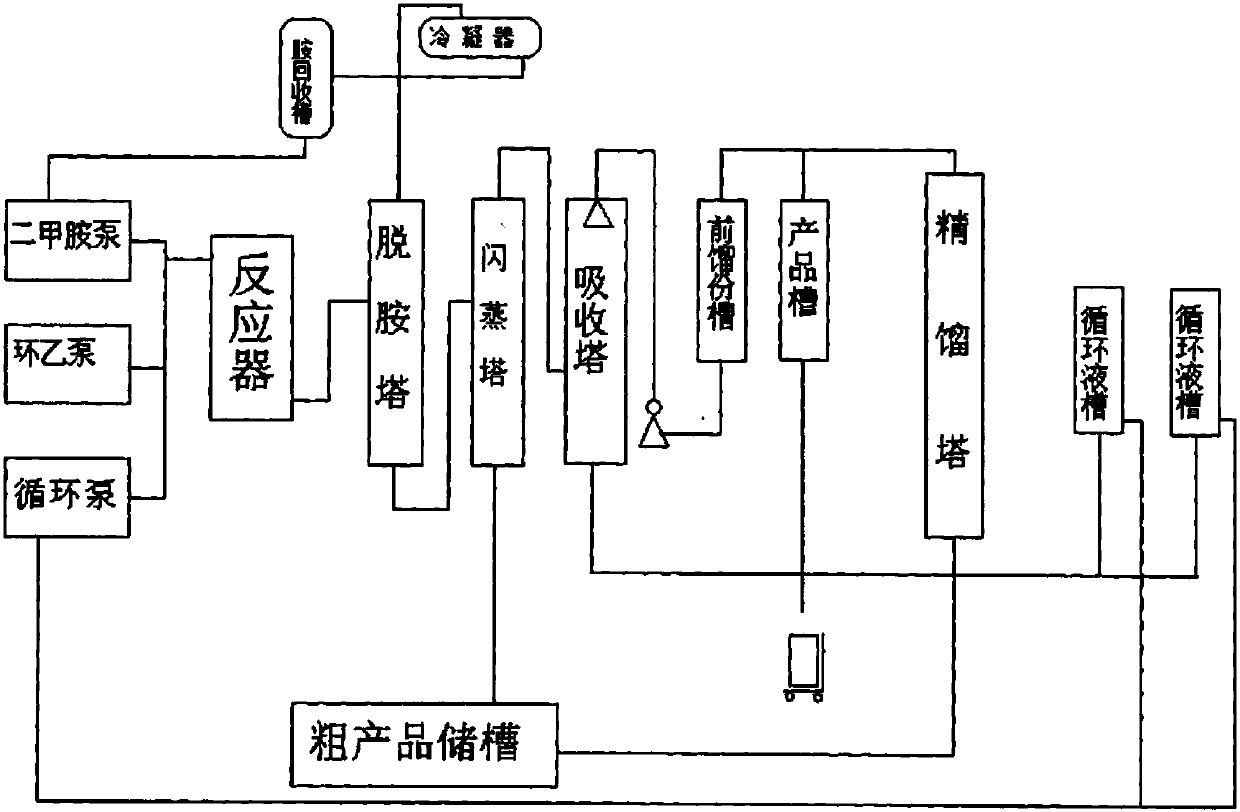

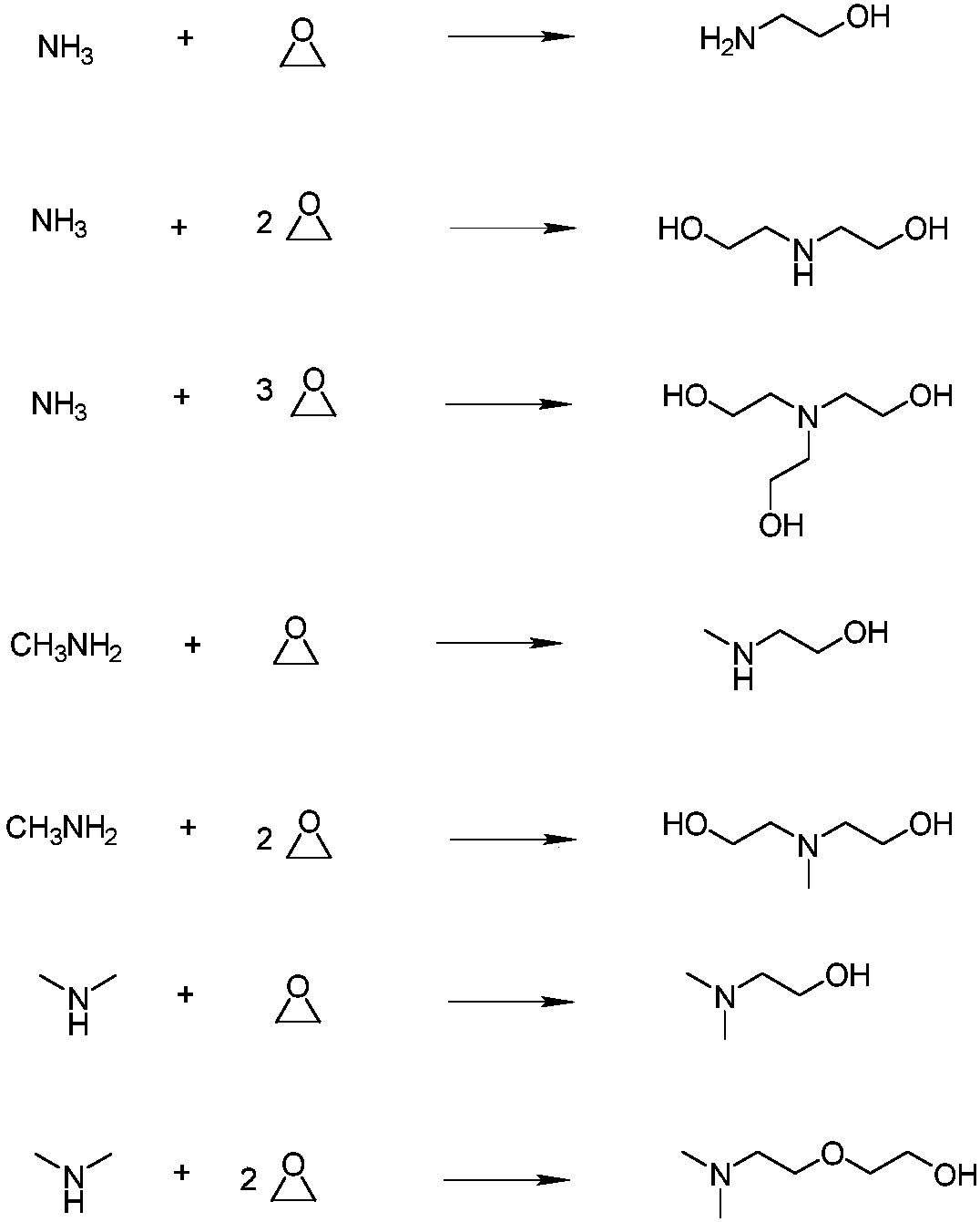

Method for continuously synthesizing ethanol amine and derivative thereof through micro-tube reaction-rectification coupling

A technology of rectification coupling and microtubular reaction, which is applied in the preparation of organic compounds, chemical instruments and methods, and the preparation of aminohydroxyl compounds. Effects of reducing waste water discharge and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

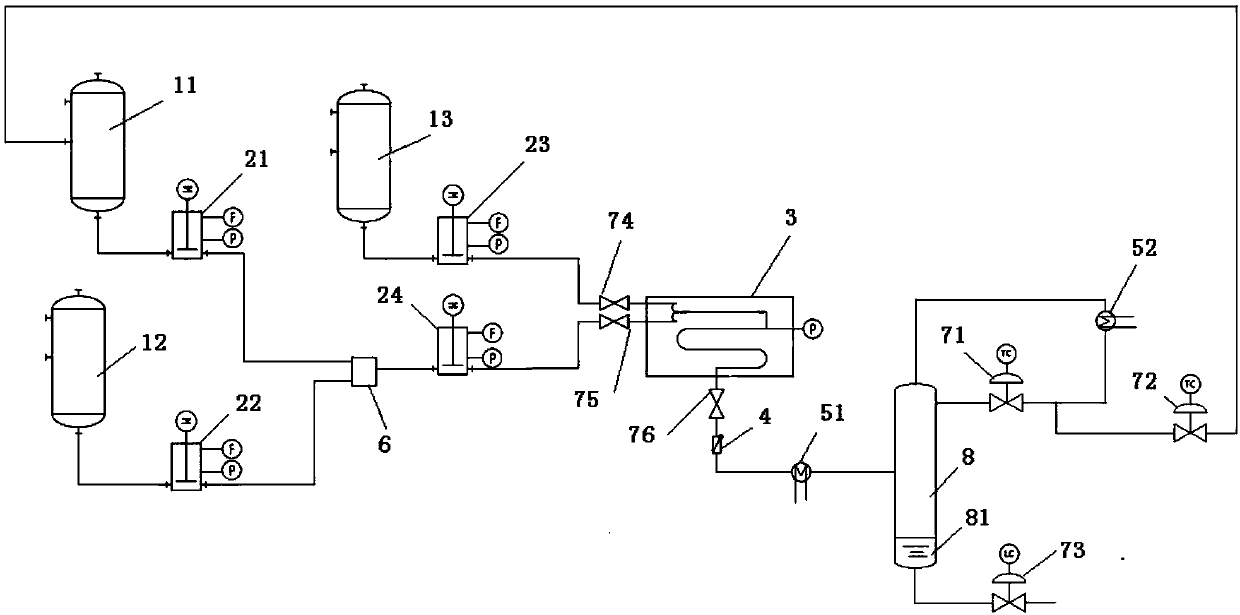

[0050] Embodiment 1, the preparation method of MEA in a kind of microtube reactor, take ethylene oxide and liquefied ammonia as raw material, take water as catalyst, carry out following steps successively:

[0051] (1) Mixing of raw materials: first mix liquid ammonia and water / circulating water, and then pass into the microtube reactor 3 together with ethylene oxide, the mass ratio of liquid ammonia to water is 1:2, and ethylene oxide and The molar ratio of liquid ammonia is 1:1;

[0052] Remarks: At the beginning of the reaction, water is used; afterward, circulating water can be used.

[0053] (2) Synthetic reaction: adjust the back pressure valve 4 to keep the pressure in the microtube reactor 3 at 1.5MPa, the temperature is controlled at 80°C, the residence time is controlled at 30s, and the reaction solution of monoethanolamine is obtained after the reaction is completed;

[0054] (3) Distillation circulating water treatment: The reaction solution is subjected to vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com