Self-supporting palladium-based catalyst as well as preparation method and application thereof

A catalyst, self-supporting technology, applied in catalyst activation/preparation, carbon monoxide or formate reaction preparation, chemical instruments and methods, etc., can solve the problem of high loading of precious metal Pd, catalyst bed "hot spots, and difficulty in reactor heat transfer" and other problems, to achieve the effect of controllable structure, easy molding, good mass and heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

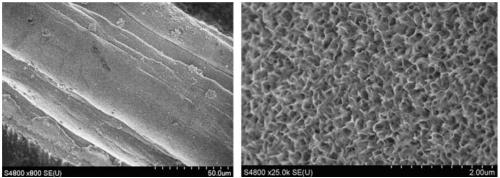

[0058] ① Weigh 4 grams of aluminum fiber (fiber diameter 80 microns, length 4-10 mm), soak it in 1.0 wt% sodium hydroxide aqueous solution at room temperature for 3-10 minutes, wash with distilled water and transfer to 100 ml Stainless steel autoclave, add distilled water until the aluminum fibers are completely submerged, seal the autoclave and place it in an oven for static hydrothermal treatment at 120°C for 24 hours, wash with distilled water and dry to obtain aluminum fiber-porous pseudoboehmite composite carrier;

[0059] 2. Dissolve 0.0260 g of palladium acetate in acetone solution, then weigh 0.1109 g of 3-aminopropyltriethoxysilane and add it to the palladium acetate in acetone solution; weigh step 1. Gained aluminum fiber-porous pseudoboehmite composite carrier 4 gram, was added to the palladium acetate acetone solution complexed by 3-aminopropyltriethoxysilane, dried after equal volume impregnation at room temperature; said 0.1032 g of sodium nitrate was dissolved i...

Embodiment 2

[0070] 1. with step 1. in embodiment 1;

[0071] 2. With the acetone solution containing 0.0260 gram of palladium acetate, impregnate 4 grams of step 1. Gained aluminum fiber-porous pseudo-boehmite composite carrier, after drying, place in high-purity N 2 Pyrolysis treatment at 350°C under protection for 1 hour, cooling to room temperature and taking out, the self-supporting carbon-modified metal palladium catalyst of the present invention was obtained, and the mass contents of Pd and C were respectively 0.26% and 0.1% by elemental quantitative analysis. %, recorded as 0.26Pd-0.1C / Al80-fiber.

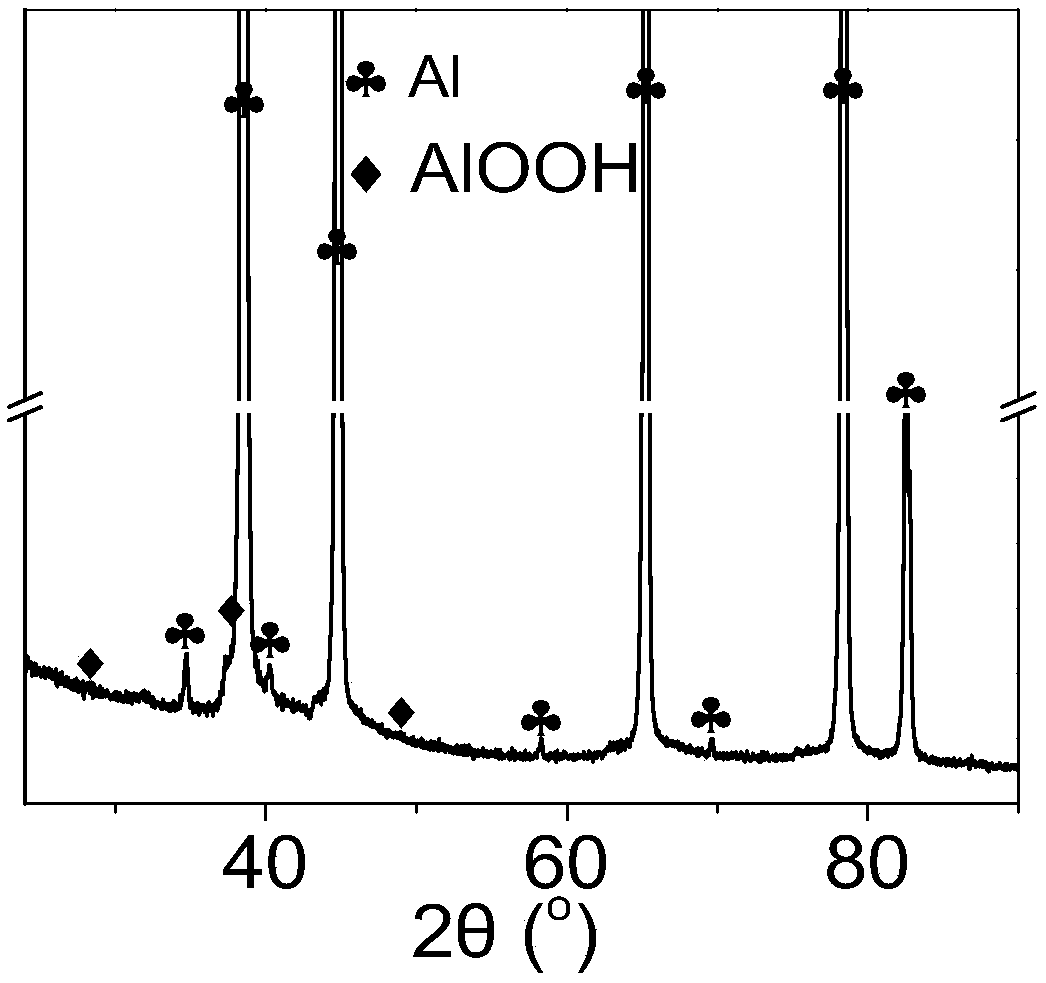

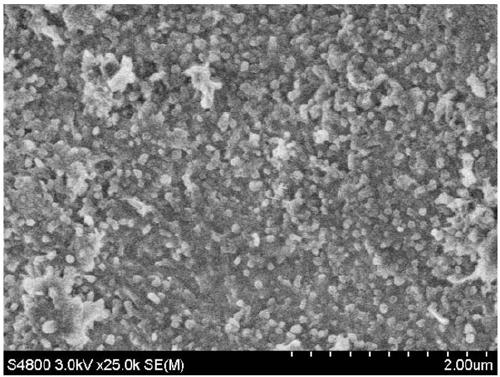

[0072] Figure 4 , Figure 5 with Image 6 X-ray diffraction spectrum, scanning electron microscope (SEM) and transmission electron microscope (TEM) of the self-supporting carbon-modified metal palladium catalyst 0.26Pd-0.1C / Al80-fiber prepared for this example. Depend on Figure 4 It can be seen that in addition to the diffraction peak of aluminum fiber, the diffraction peak of ps...

Embodiment 3

[0075] 1. Weigh 10 grams of aluminum fiber felt (fiber diameter 60 microns), soak it in 2.0 wt% sodium hydroxide aqueous solution at room temperature for 3 to 10 minutes, wash it with distilled water and transfer it to a 100 ml stainless steel autoclave, add Distill water until the aluminum tube is completely submerged, seal the kettle and place it in an oven for static hydrothermal treatment at 120°C for 2 hours, wash with distilled water and dry to obtain the aluminum fiber felt-porous pseudo-boehmite composite carrier;

[0076] 2. With the acetone solution containing 0.026 gram of palladium acetate, impregnate 4 grams of aluminum fiber mat-porous pseudo-boehmite composite carrier obtained in step 1. After drying, place in high-purity N 2 Pyrolysis treatment at 350°C under protection for 1 hour, cooling to room temperature and taking out, the self-supporting carbon-modified metal palladium catalyst of the present invention was obtained, and the mass content of Pd and C were r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com