High temperature high pressure synthesis method for polycarbosilane

A technology of polycarbosilane and a synthesis method, which is applied in the field of high temperature and high pressure synthesis of polycarbosilane, can solve the problems of low Si-H bond content, low yield of synthetic PCS, low molecular weight of PCS, etc., so as to shorten the reaction time and increase the reaction pressure. , the effect of increasing the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with embodiment.

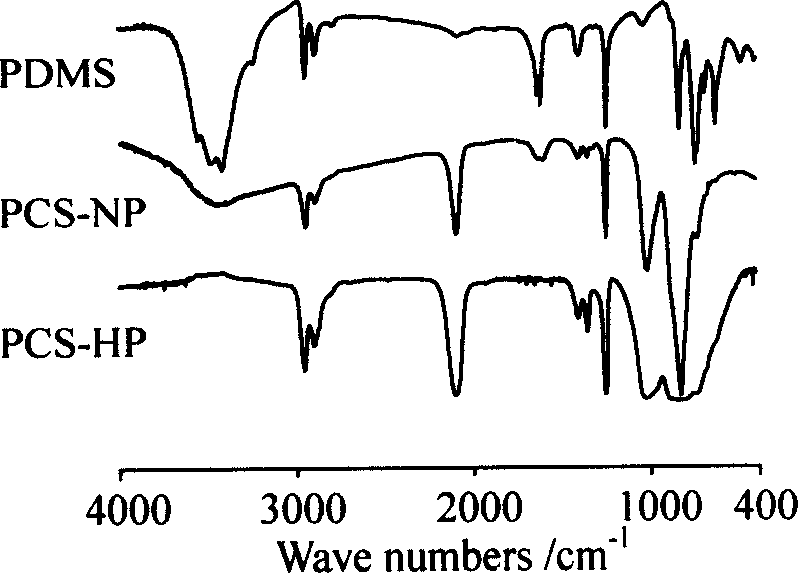

[0014] (1) Using PDMS as the embodiment of high temperature and high pressure synthesis of PCS

[0015] Put 250g of PDMS in the autoclave, repeatedly vacuumize and replace the gas in the autoclave with high-purity nitrogen, and finally add 0.5Mpa of N 2 , sealed; then the temperature was programmed to 450 ° C, reacted for 6h, and after cooling, the crude product of PCS was obtained. The crude product was dissolved in xylene, filtered, and the filtrate was distilled under reduced pressure at 350° C., and the PCS precursor (PCS-HP) in the form of brownish yellow resin was obtained after cooling.

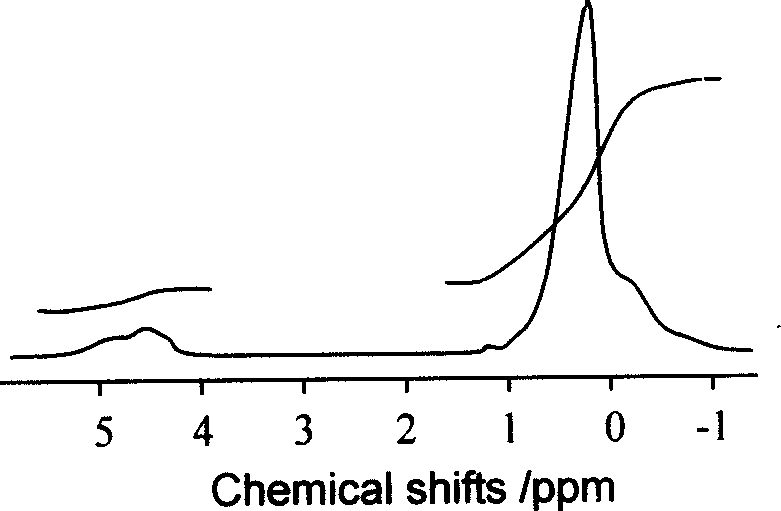

[0016] The following is an evaluation of the present invention based on the composition structure, Si-H bond content, yield, molecular weight and other characteristics of PCS-HP, and compared with the characteristics of PCS-NP synthesized at normal pressure with a similar softening point.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com