Carbonation reactor of energy-efficient nano calcium carbonate and preparation method of energy-efficient nano calcium carbonate

A nano-calcium carbonate, reactor technology, applied in the direction of calcium carbonate/strontium/barium, nanotechnology, nanotechnology, etc., can solve the problems of high production cost, high energy consumption, restricting the expansion of the application field of nano-calcium carbonate production, etc., Achieve the effect of saving energy consumption and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

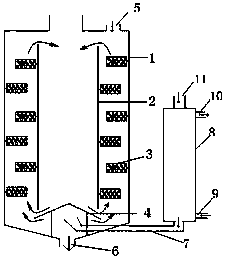

[0016] Such as figure 1 Shown: The diameter of the reactor shell is 1.2 meters, the height is 5.0 meters, the diameter of the inner cylinder is 0.6 meters, and the height is 4.0 meters. The width of the spiral baffle inside the shell is 25 cm, and the length is 20 cm. The inclination angle spirals are arranged and installed at intervals upwards.

[0017] Inject 4.5 cubic meters of calcium hydroxide slurry with a mass concentration of 9.0% into the reactor, add 3.0 kg of crystal form control agent sucrose, the initial temperature of the calcium hydroxide slurry is 25°C, and a Roots blower with a pressure of 78Kpa is used , after compressing the kiln gas, cool it with deep well water to below 25°C, and then enter the umbrella-shaped gas distributor, control the flow rate of the kiln gas to 9 cubic meters per minute, the volume content of carbon dioxide in the kiln gas is 26-30%, carbonization 60 Minutes later, the temperature of the slurry rises to 33°C, and the pH value of th...

Embodiment 2

[0019] With the same equipment and similar method of Example 1, 4.5 cubic meters of calcium hydroxide slurry with a mass concentration of 8.0% were injected into the reactor, 2.5 kilograms of crystal form control agent sucrose were added, and the initial temperature of the calcium hydroxide slurry was When the temperature is 24°C, the kiln gas is compressed and cooled to below 24°C with deep well water, and then enters the umbrella-shaped gas distributor to control the flow rate of the kiln gas to 7 cubic meters per minute, and the volume content of carbon dioxide in the kiln gas is 26-30% After 66 minutes of carbonization, the temperature of the slurry rises to 31°C, and the pH value of the material drops to 6.5-7.0, which is the end of carbonization. The particle diameter of the calcium carbonate slurry synthesized by carbonization in the reactor is 80-130 nanometers measured by the transmission electron microscope, the particle diameter distribution is uniform, the dispersib...

Embodiment 3

[0021] With the same equipment and similar method of Example 1, 4.5 cubic meters of calcium hydroxide slurry with a mass concentration of 7.2% were injected into the reactor, 3.0 kilograms of crystal form control agent sucrose were added, and the initial temperature of the calcium hydroxide slurry was The temperature is 24°C. Compress the kiln gas and cool it to below 23°C with deep well water, then enter the umbrella-shaped gas distributor, control the flow rate of the kiln gas to 7 cubic meters per minute, and the volume content of carbon dioxide in the kiln gas to be 26-30% After 60 minutes of carbonization, the temperature of the slurry rises to 30°C, and the pH value of the material drops to 6.5-7.0, which is the end of carbonization. The calcium carbonate slurry synthesized by carbonization in the reactor has a particle size of 70-100 nanometers measured by a transmission electron microscope, uniform particle size distribution, good dispersibility and no agglomeration phe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com