A kind of polyolefin flame retardant masterbatch and its preparation method and application

A technology of flame retardant masterbatch and polyolefin, which is applied in the field of polyolefin flame retardant masterbatch and its preparation, can solve the problems of poor compatibility, achieve the effects of improved compatibility, improved flame retardant performance, and great promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

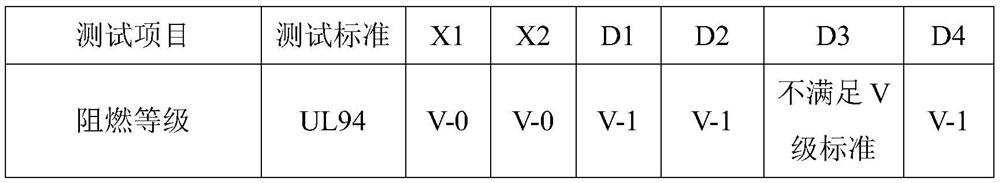

Examples

Embodiment 1

[0031] (1) Weigh 400gMgCl 2 ·6H 2 O, 600gAlCl 3 ·6H 2 O. 2.4kg of deionized water was added to the reaction vessel, stirred and reacted at 90°C for 4h to prepare solution A.

[0032] (2) Weigh 200g of potassium hydroxide, 300g of potassium carbonate, and 1.6kg of deionized water, add them into a reaction vessel, stir and react for 3 hours at room temperature, and prepare solution B.

[0033] (3) Weigh 800 g of solution A, 200 g of solution B, and 30 g of sodium dodecylbenzenesulfonate, add them into a reaction vessel, stir and react at 100°C for 8 hours, and prepare solution C.

[0034] (4) Place solution C at room temperature for aging, remove the upper clarified liquid, suction filter the white turbid liquid in the lower layer, wash with deionized water, dry, pulverize, and pass through a 600-mesh sieve to obtain the modified LDH .

[0035] (5) Weigh 200g modified LDH, 240g melamine pyrophosphate (MPP), 80g pentaerythritol (PER), 600gPP, 3g erucamide, 3g antioxidant 101...

Embodiment 2

[0039] (1) Weigh 300gMgCl 2 ·6H 2 O, 500gAlCl 3 ·6H 2 O. 2.0kg of deionized water was added to the reaction vessel, stirred and reacted at 70°C for 2h, and solution A was prepared.

[0040] (2) Weigh 100g of potassium hydroxide, 200g of potassium carbonate, and 1.0kg of deionized water, add them into a reaction vessel, stir and react at room temperature for 1 hour, and prepare solution B.

[0041] (3) Weigh 600g of solution A, 100g of solution B, and 10g of sodium dodecylbenzenesulfonate, add them into a reaction vessel, stir and react at 80°C for 6h, and prepare solution C.

[0042] (4) Place solution C at room temperature for aging, remove the upper clarified liquid, suction filter the white turbid liquid in the lower layer, wash with deionized water, dry, pulverize, and pass through a 600-mesh sieve to obtain the modified LDH .

[0043] (5) Weigh 100g modified LDH, 200g melamine pyrophosphate (MPP), 60g pentaerythritol (PER), 400gPP, 1g erucamide, 1g antioxidant 1010, ...

Embodiment 3

[0075] (1) Weigh 350gMgCl 2 ·6H 2 O, 550gAlCl 3 ·6H 2 O. 2.2kg of deionized water was added to the reaction vessel, stirred and reacted at 80°C for 3h, and solution A was prepared.

[0076] (2) Weigh 150g of potassium hydroxide, 250g of potassium carbonate, and 1.3kg of deionized water, add them into a reaction vessel, stir and react at room temperature for 2 hours, and prepare solution B.

[0077] (3) Weigh 700 g of solution A, 150 g of solution B, and 20 g of sodium dodecylbenzenesulfonate, add them into a reaction vessel, stir and react at 90° C. for 7 hours, and prepare solution C.

[0078] (4) Place solution C at room temperature for aging, remove the upper clarified liquid, suction filter the white turbid liquid in the lower layer, wash with deionized water, dry, pulverize, and pass through a 600-mesh sieve to obtain the modified LDH .

[0079] (5) Weigh 150g modified LDH, 220g melamine pyrophosphate (MPP), 70g pentaerythritol (PER), 500g polyethylene (PE), 2g eruca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com