Circumferential seam butt welding protection device

A protection device and butt welding technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of reducing the service life of welding products, easy deformation of plates, difficult to cool and protect the back of the weld, and ensure welding quality , to avoid the effect of crevice corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

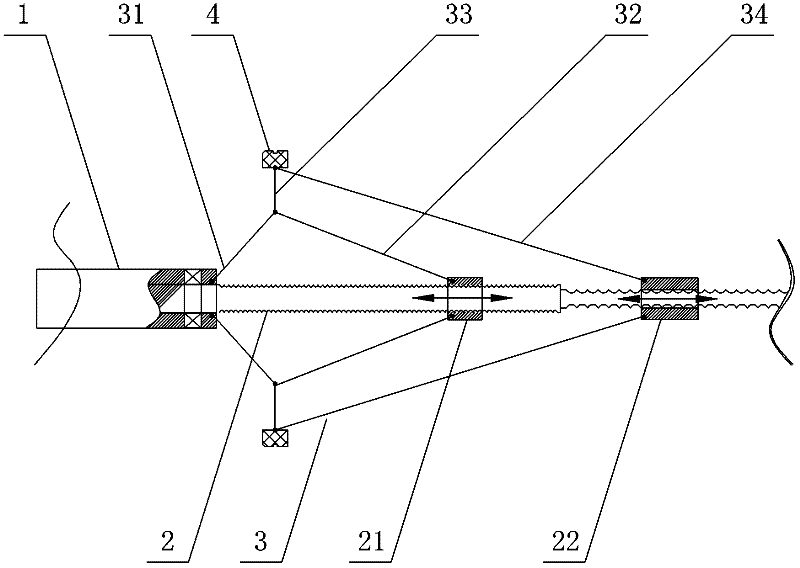

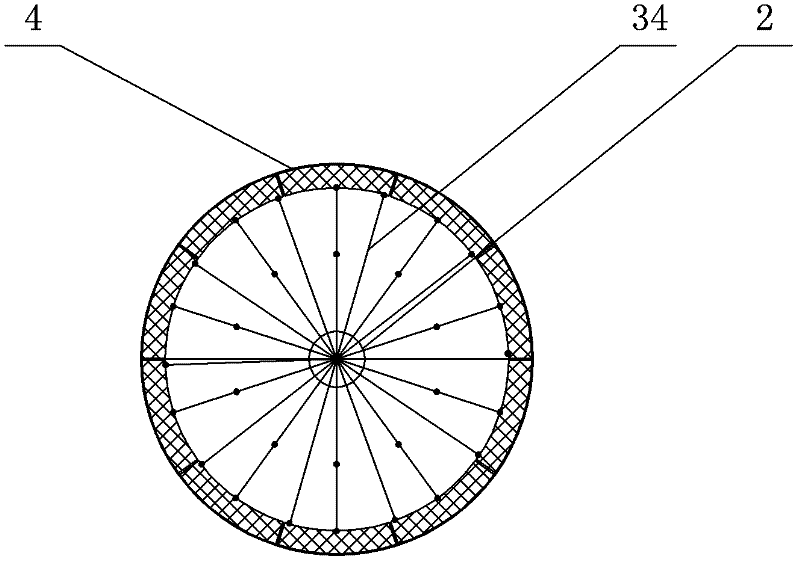

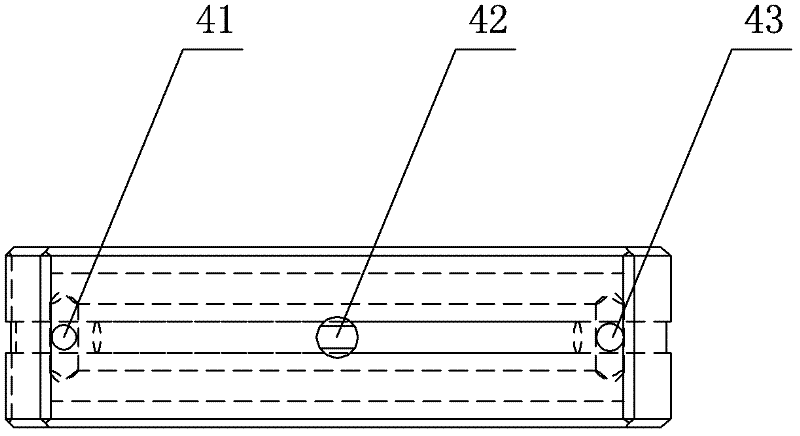

[0022] see Figure 1-Figure 8 , a circular seam butt welding protection device, including a fixed sleeve 1 and a rotating shaft 2, one end of the rotating shaft inserted into the fixed sleeve 1. The rotating shaft 2 is provided with two threads with different pitches, the first thread section is provided with an opening and closing slider 21 , and the second thread section is provided with a rotating slider 22 . A plurality of link mechanisms 3 are arranged on the fixed sleeve 1 , and the link mechanisms include: a first link 31 , a second link 32 , a support bar 33 , a rotating link 34 and a rear protection cooling block 4 . One end of the first connecting rod is connected with the fixed sleeve 1, one end of the second connecting rod 32 is connected with the opening and closing slider 21, and the supporting rod 33 is arranged at the junction of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com