High-carbon dephosphorization method for high-carbon steel in converter smelting

A converter smelting, medium-high-carbon technology, which is applied in the field of high-carbon dephosphorization of medium-high carbon steels in converter smelting, can solve the problems of re-phosphorization of steel and low smelting rate, so as to improve the basicity of final slag, shorten the smelting time, The effect of maintaining dephosphorization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

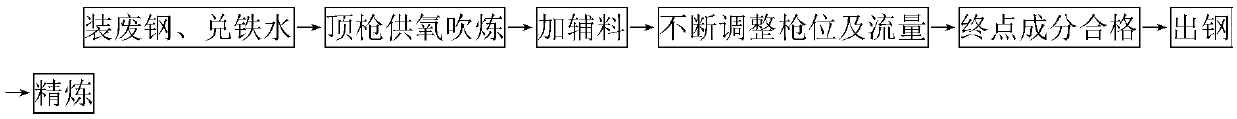

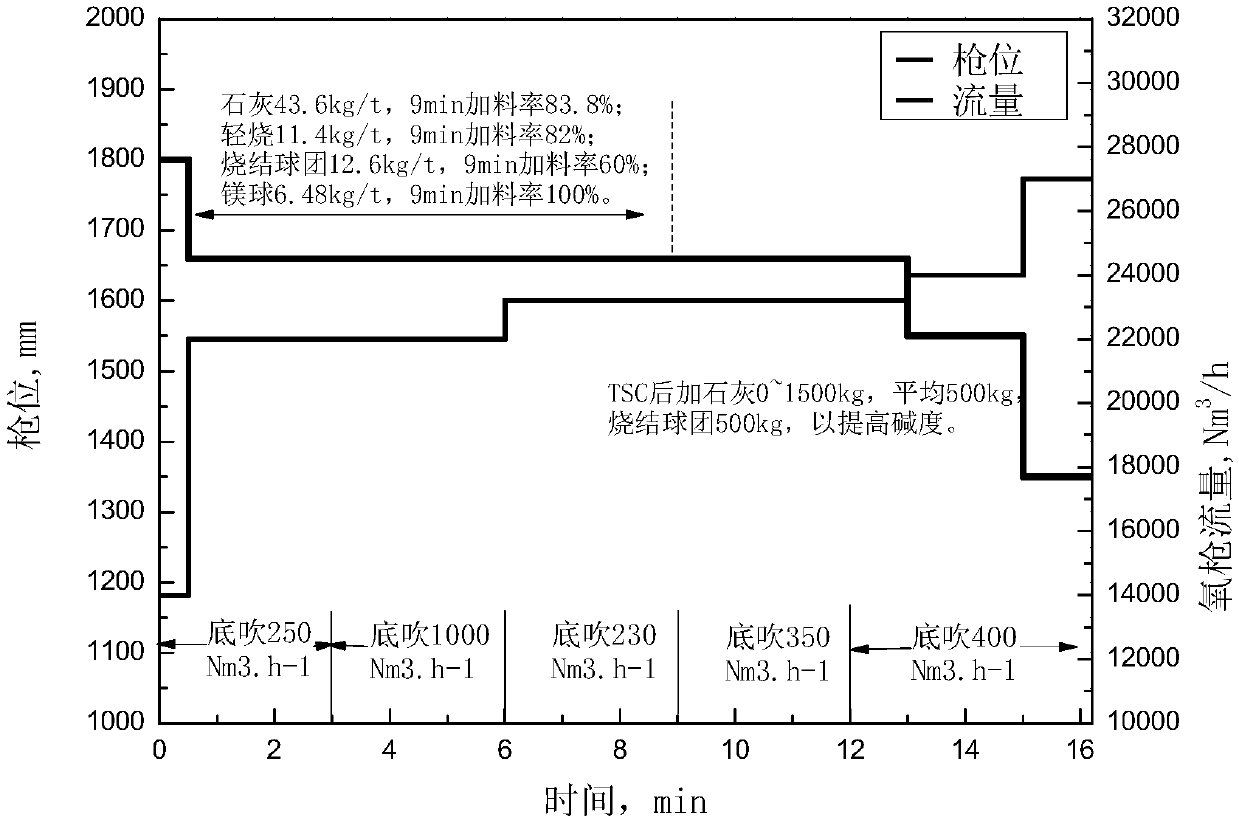

[0025] In order to realize the metallurgical effect of high-carbon dephosphorization when the converter produces medium-high carbon steel, the process of the present invention was implemented in a 120t converter in a special domestic steel factory. 131t, the molten iron ratio is 89.3%, and the tapping volume is 125t. The molten iron conditions are: 4.32% [C], 0.41% [Si], 0.17% [Mn], 0.12% [P], 0.02% [S], and the temperature is 1302°C. Pre-operation: increase the strength of the bottom blowing in the early stage to 0.13Nm 3 / min / t, oxygen supply intensity 2.8Nm 3 / min / t, gun position 180cm in 0~0.5min, 165cm in 0.5~6min, 43.6kg of lime added per ton of steel, and >80% slagging material added in 0~9min. Mid-term operation: bottom blowing strength 0.03~0.045Nm 3 / min / t, oxygen supply intensity 2.9Nm 3 / min / t, gun position 165cm. Post operation: Oxygen supply intensity 3.2Nm 3 / min / t, gun position 155cm, add lime 500kg, sinter 500kg. Final operation: pressure gun for 1-1.5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com