Circular seam welding tool for enclosed container

A technology of girth welding and airtight containers, which is applied in the field of welding tooling and girth welding of stainless steel thin plate airtight containers, which can solve the problems of reducing the service life of welded products, small restraint of thin plates, and burn-through, so as to avoid excessive oxidation of weld seams , Avoid crevice corrosion and prevent excessive oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In conjunction with the accompanying drawings, the invention will be further described by taking the implementation of argon-arc circular seam welding tooling for a rectangular cylinder body and a stainless steel airtight container as an example. In this embodiment, compressed air is selected as the power for control. The embodiment is connected with external welding torch system, power supply system and shielding gas system.

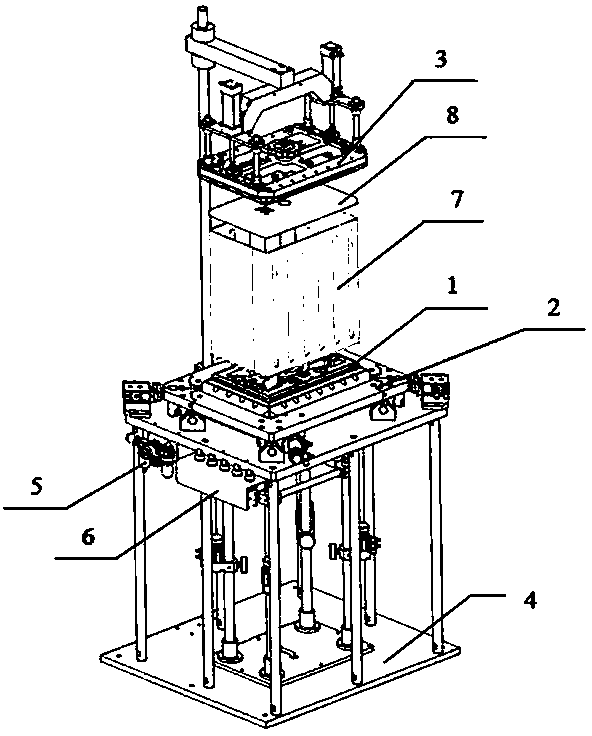

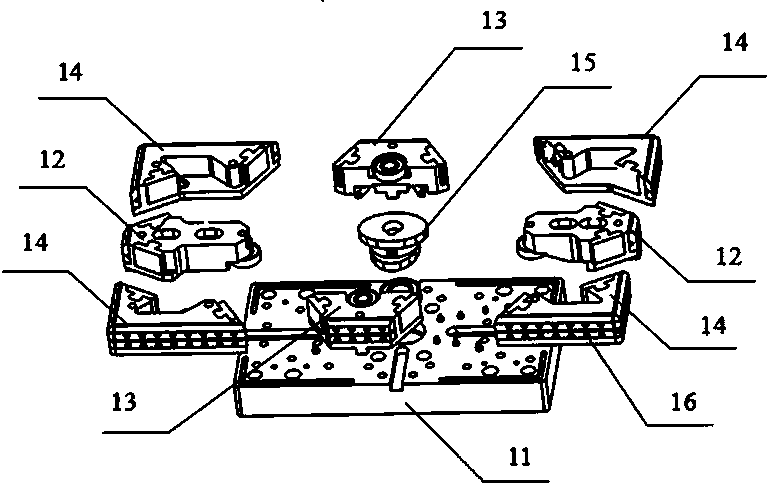

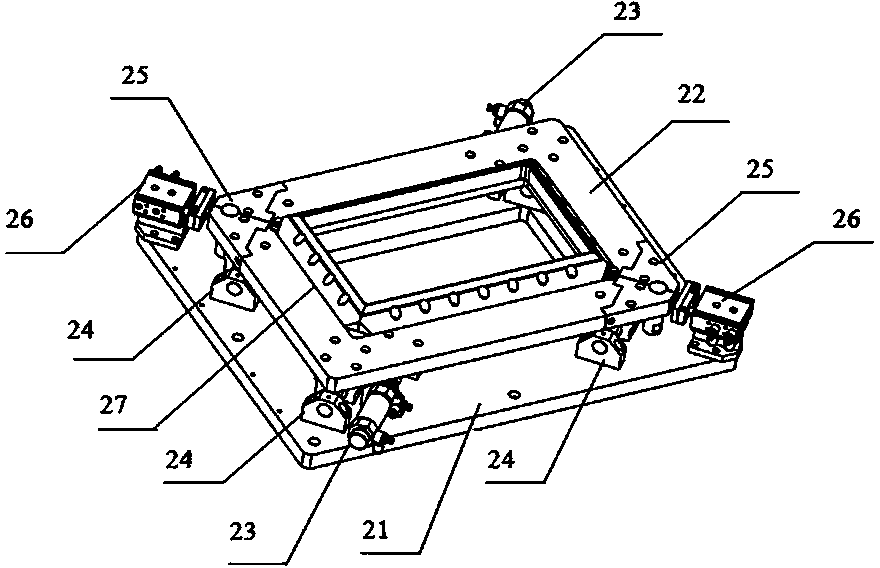

[0025] Such as Figure 1-Figure 9 As shown, the girth welding tool is composed of four major components: plane slider mechanism 1, cylinder body fixture 2, end cover fixture 3, and main frame 4. The plane slider mechanism 1 is connected to the inner connecting rod 42 of the main frame 4, The barrel clamp 2 is connected to the outer link 43 of the main frame 4, the end cover fixture 3 is connected to the support beam 44 of the main frame 4, and the air intake device 5 and the control switch group 6 can be installed on the barrel fixture 2 as stand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com