Membrane reactor for use in hydrocarbon oxidization reaction-separation coupling process

A technology of oxidation reaction and membrane reactor, which is applied in the direction of oxidation reaction preparation, hydrocarbon oxidation preparation of oxygenated compounds, chemical/physical processes, etc. It can solve the problems of low conversion rate of raw materials, excessive oxidation formation, and low selectivity of target products. To achieve the effect of improving selectivity, reducing the generation of by-products and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

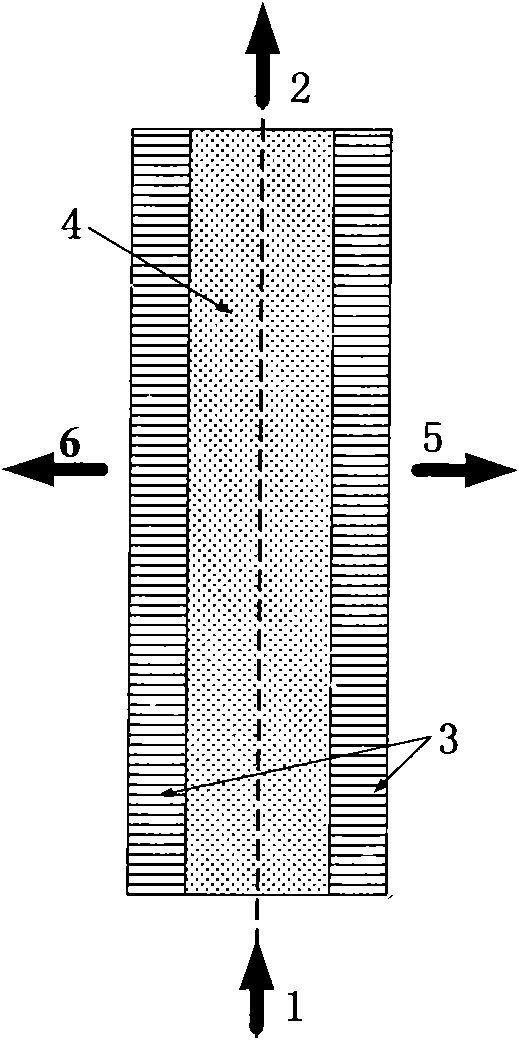

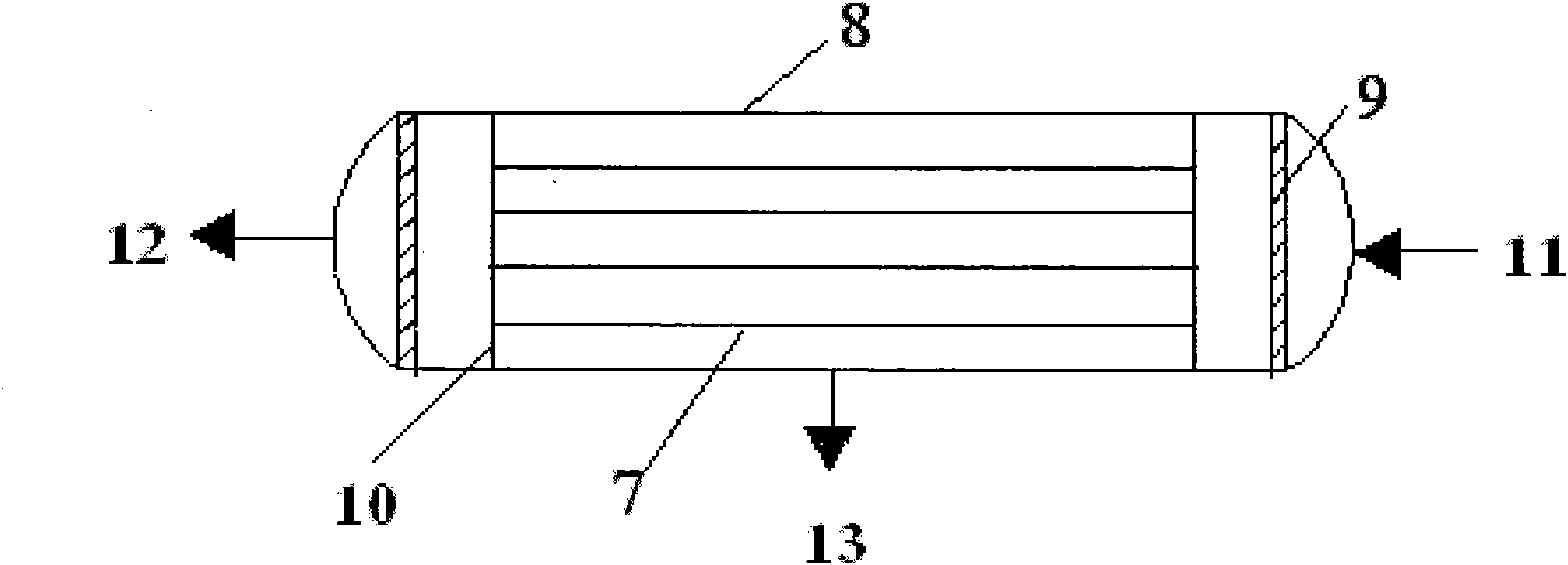

[0021] The structure of the membrane reactor is to make the finished inorganic ceramic microfiltration membrane tube into a fiber bundle and install it in a pressure-resistant steel shell. The two ends of the membrane tube are supported by porous polytetrafluoroethylene plates. Both the body junction and the junction with the membrane tube are sealed with resin casting. The structure of the membrane tube (see figure 1 ) is an inorganic ceramic microfiltration membrane tube, and the micropores are filled with a polymer membrane material with the performance of selectively separating cyclohexane / cyclohexanol (ketone) mixtures. The catalyst for heaping cyclohexane oxidation reaction in the tube is specifically a nano-gold molecular sieve catalyst. Inorganic ceramic microfiltration membrane tube, the filling method of microporous polymer is as follows:

[0022] Fill the inorganic ceramic microfiltration membrane tube with a certain concentration of polymer solution, let the poly...

Embodiment 2

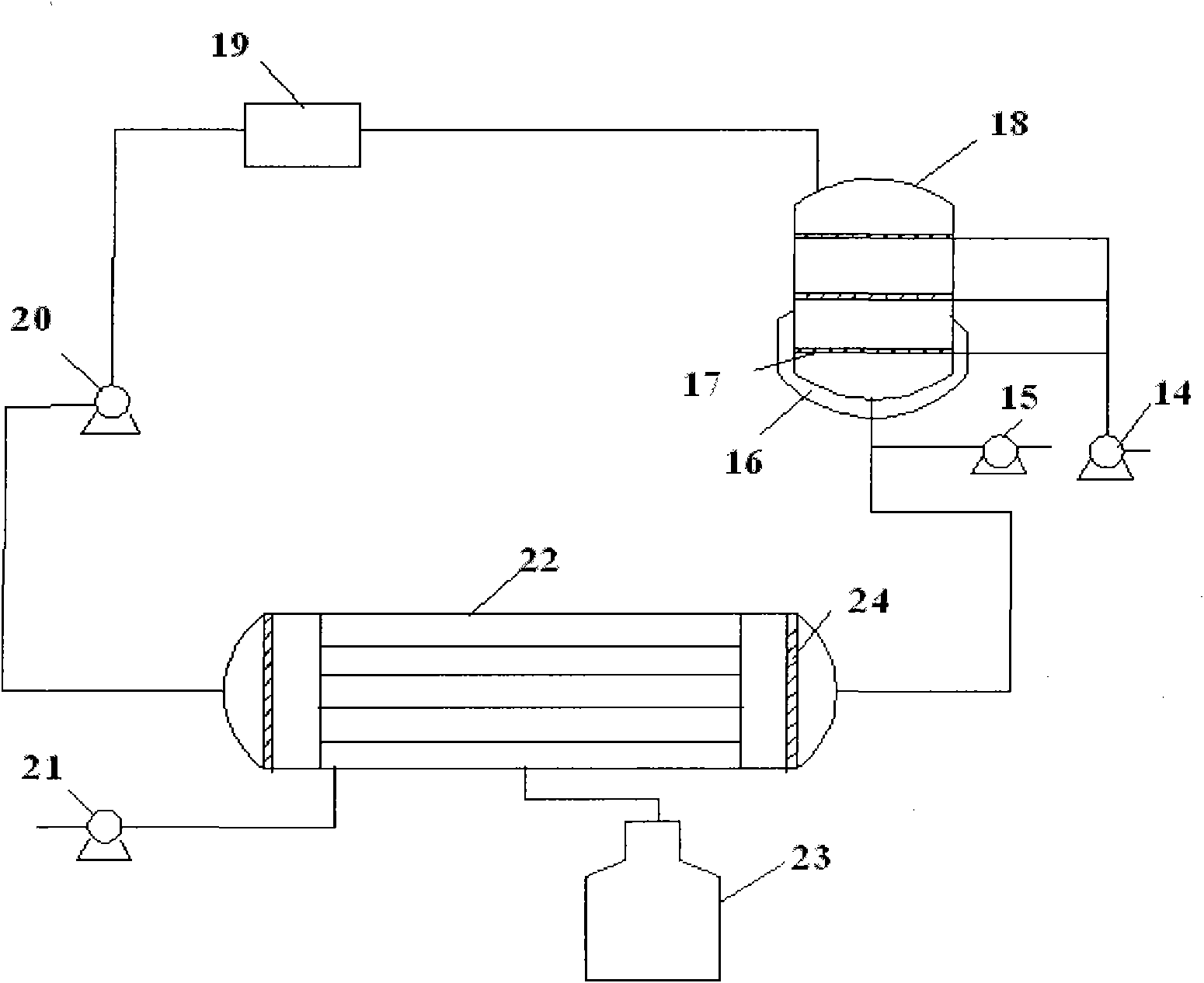

[0029] as attached image 3As shown, with feed liquid pump 15, 4L hexanaphthene is pumped into the raw material still 18 that effective volume is 5L, and the oxygen that comes in from oxygen pump 14 passes gas sparger 17 with hexanaphthene in the raw material with the amount of 1.5L / min. Bubbling and mixing in the kettle, the heating jacket 16 heats the raw material liquid to 150°C, the flow rate of the raw material liquid is controlled to 10m / s, the pressure is 1MPa, and the liquid distributor 24 at the feed end of the membrane reactor 22 enters the inorganic ceramic microfiltration tube for oxidation reaction , the vacuum pump 21 is used outside the tube to maintain the pressure in the shell of the membrane reactor at about 200 Pa, and the liquid mixture in the tube is driven by the component vapor partial pressure difference, utilizing the dissolution and diffusion speed of the component through the separation membrane material If it is different, the partially oxidized pro...

Embodiment 3

[0031] as attached image 3 As shown, with feed liquid pump 15, 4L hexanaphthene is pumped into the raw material still 18 that effective volume is 5L, and the oxygen that comes in from oxygen pump 14 passes gas sparger 17 with hexanaphthene in the raw material with the amount of 1.5L / min. Bubble mixing in the kettle, heating jacket 16 to heat the raw material liquid to 140°C, control the flow rate of the raw material liquid to 15m / s, the pressure to 0.6MPa, and enter the inorganic ceramic microfiltration tube through the liquid distributor 24 at the feed end of the membrane reactor 22 for oxidation Reaction, the vacuum pump 21 is used outside the tube to maintain the pressure in the shell of the membrane reactor at about 200Pa, and the liquid mixture in the tube is driven by the partial pressure difference of the component vapor, and the dissolution and diffusion speed of the component through the separation membrane material is utilized. Part of the oxidation product will ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com