Nickel-based composite powder of laser cladding coating and method for preparing coating

A composite powder and laser cladding technology, applied in the field of nickel-based composite powder and preparation of coatings, can solve the problems of no cracks, insufficient hardness, etc., to improve the process forming performance, improve corrosion resistance, and no cracks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The composition of the laser cladding nickel-based composite powder in this embodiment is as follows by weight percentage: C: 0.572%, Cr: 15.5%, Si: 3.1%, W: 2.1%, Fe: 32.4%, Mn: 0.3%, B: 2.45 %, Cu: 0.3%, Nb: 0.135%, and the balance is Ni.

[0024] The specific method for preparing the coating by laser cladding in the embodiment of the present invention is as follows:

[0025] Step 1: In manual mode, control the robot to aim the laser head at the surface of the workpiece. Before cladding, put the powder into the drying box and heat it to 150°C and keep it warm for 0.5h for drying treatment; degrease the surface of the workpiece, derusting treatment;

[0026] Step 2: Use synchronous coaxial powder feeding, that is, the powder feeding direction is consistent with the laser incident direction, and the powder is sent to the surface of the workpiece to be clad;

[0027] Step 3: Feed the nickel-based composite powder through coaxial powder feeding during laser cladding, an...

Embodiment 2

[0030] The composition of the laser cladding nickel-based composite powder in this embodiment is as follows by weight percentage: C: 0.648%, Cr: 15.9%, Si: 3.4%, W: 2.4%, Fe: 26.8%, Mn: 0.2%, B: 2.8 %, Cu: 1.0%, Nb: 0.09%, and the balance is Ni.

[0031] The method of preparing the coating is the same as in Example 1.

Embodiment 3

[0033] The composition of the laser cladding nickel-based composite powder in this embodiment is as follows by weight percentage: C: 0.724%, Cr: 16.1%, Si: 3.7%, W: 2.7%, Fe: 29.8%, Mn: 0.1%, B: 3.15% %, Cu: 1.5%, Nb: 0.015%, and the balance is Ni.

[0034] The method of preparing the coating is the same as in Example 1.

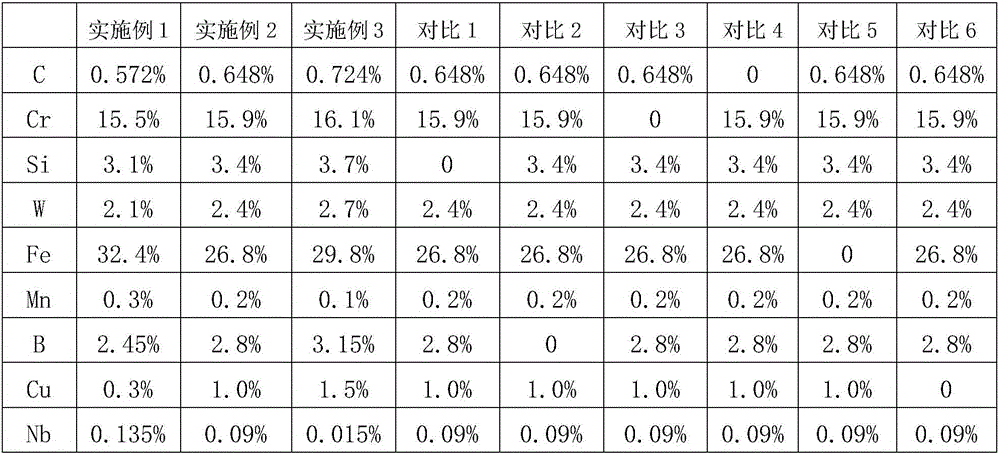

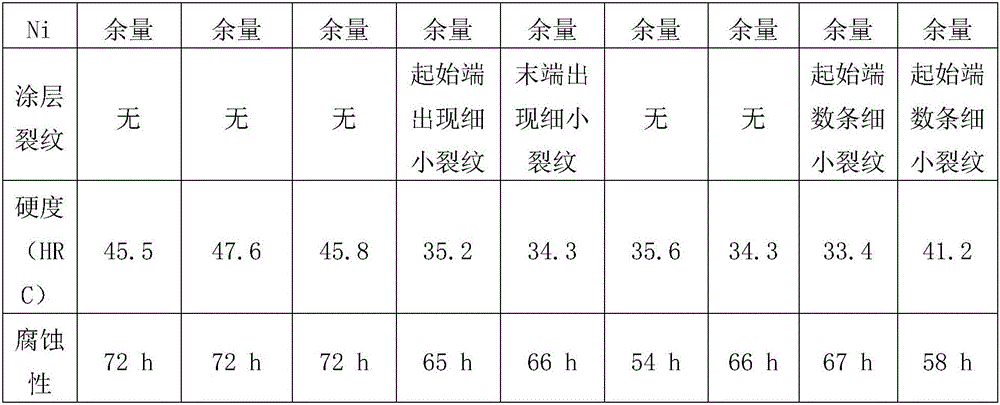

[0035] The components of comparative examples and the performance of the prepared coating are shown in table 1:

[0036] Table 1

[0037]

[0038]

[0039] It can be concluded from Table 1 that the B and Si elements in the nickel-based composite powder can improve the fluidity and wettability of the metal, obtain a well-formed coating on the surface, and have the function of slagging, and can also form borides, and the silicides can improve Coating hardness; Cr, W, C elements can form C 23 C 6 Type carbide and WC, these hard phases increase the hardness of the coating; Ni, Fe elements can form solid solutions, which can improve the strength and har...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com