Double-layer coating on metal connector surface of high-temperature solid oxide cell and preparation method thereof

A metal connector and double-layer coating technology, which is applied in the direction of solid electrolyte fuel cells, battery pack components, fuel cell components, etc., can solve the problem of destroying the stability of perovskite oxides and the second coating is not dense , contact layer resistance increase and other issues, to achieve the effect of easy amplification and large-scale manufacturing, low surface specific resistance, and avoid oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

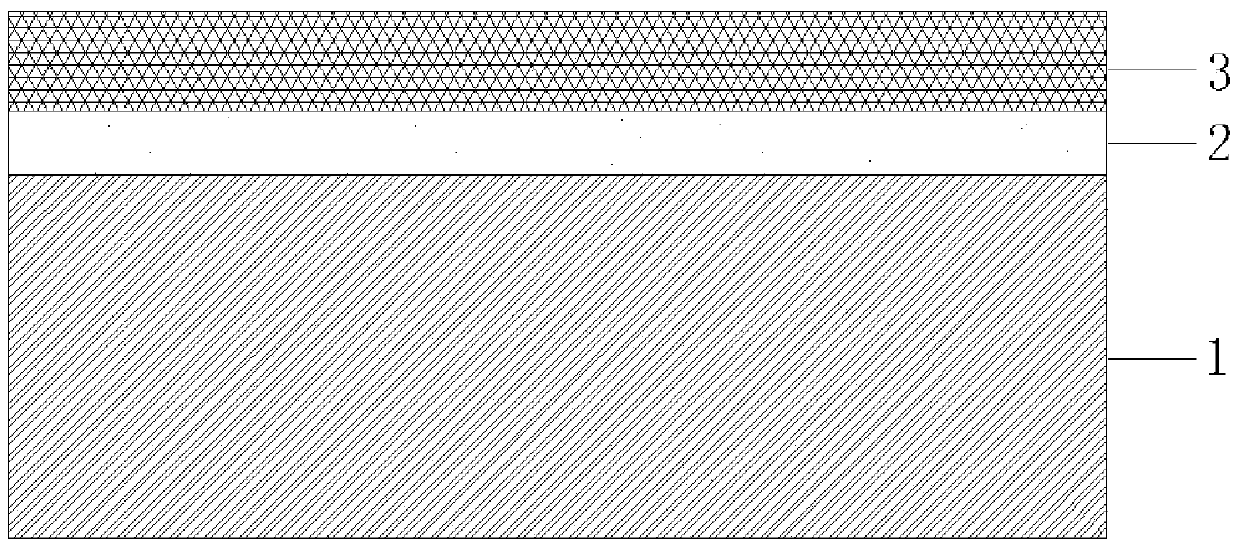

[0050] This embodiment relates to a double-layer coating on the surface of a metal connector of a high-temperature solid oxide battery and a preparation method; the structure of the double-layer coating is as follows figure 1 As shown, it includes a first coating 2 on the base layer 1 of the metal connector, and a second coating 3 deposited on the first coating 2 . In this embodiment, SUS430 ferritic stainless steel with a chromium content of 16.0-18.0% is used as the metal substrate, and the specific preparation steps are as follows:

[0051] The first step is to electroplate pure cobalt on the surface of SUS430 ferritic stainless steel:

[0052] 1. After cutting the SUS430 stainless steel plate according to the required size, polish it with 350-mesh, 1200-mesh and 2000-mesh SiC water abrasive paper in turn until it is bright, use chemical degreasing method to degrease initially, and then soak in acetone solution for ultrasonic cleaning for 30 minutes , and finally activated...

Embodiment 2

[0066] In this embodiment, Crofer22APU ferritic stainless steel with a chromium content of 22.0-24.0% is used as the metal matrix. Electroplating cobalt-based composite coating (particles are LaCrO 3 ) as the first coat. Doped with Ce 0.8 SM 0.2 O 2-δ The double perovskite structure composite oxide PrBaCo 2 O 5+δ as a second coat. Concrete preparation steps are as follows:

[0067] The first step is to electroplate cobalt-based composite coating on the surface of Crofer22APU ferritic stainless steel:

[0068] 1. After cutting the Crofer22APU stainless steel plate according to the required size, polish it with 350-mesh, 1200-mesh and 2000-mesh SiC water abrasive paper in turn until it is bright, use chemical degreasing method to degrease, and then soak in acetone solution for ultrasonic cleaning for 30 minutes , and finally activated with a mixed solution of 5% nitric acid and 15% hydrochloric acid for 1 minute, rinsed with distilled water, and dried for later use.

[...

Embodiment 3

[0078] In this embodiment, E-brite ferritic stainless steel with a chromium content of 26.0-27.5% is used as the metal matrix. An electroplated cobalt-iron alloy coating is used as the first coating. Doped with Ce 0.75 Y 0.25 O 2-δ K 2 NiF 4 type structure composite oxide Nd 2 NiO 4+δ as a second coat. Concrete preparation steps are as follows:

[0079] The first step is to electroplate cobalt-iron alloy coating on the surface of E-brite ferritic stainless steel:

[0080] 1. After cutting the E-brite stainless steel plate according to the required size, polish it with 350-mesh, 1200-mesh and 2000-mesh SiC water abrasive paper in turn until it is bright, use chemical degreasing method to degrease initially, and then immerse in acetone solution for ultrasonic cleaning 30 minutes, and finally activated with a mixed solution of 5% nitric acid and 15% hydrochloric acid for 1 minute, rinsed with distilled water, and dried for later use.

[0081] 2. Prepare the basic platin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com