Continuous and quantitative granule filling mechanism

A feeding mechanism and filling technology, which is used in the field of continuous feeding and filling of granular materials and continuous quantitative filling of granular materials, can solve the problem of uneven filling volume, high labor intensity, and inability to meet production and use, etc. problem, to achieve the effect of reasonable structure design and avoid scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

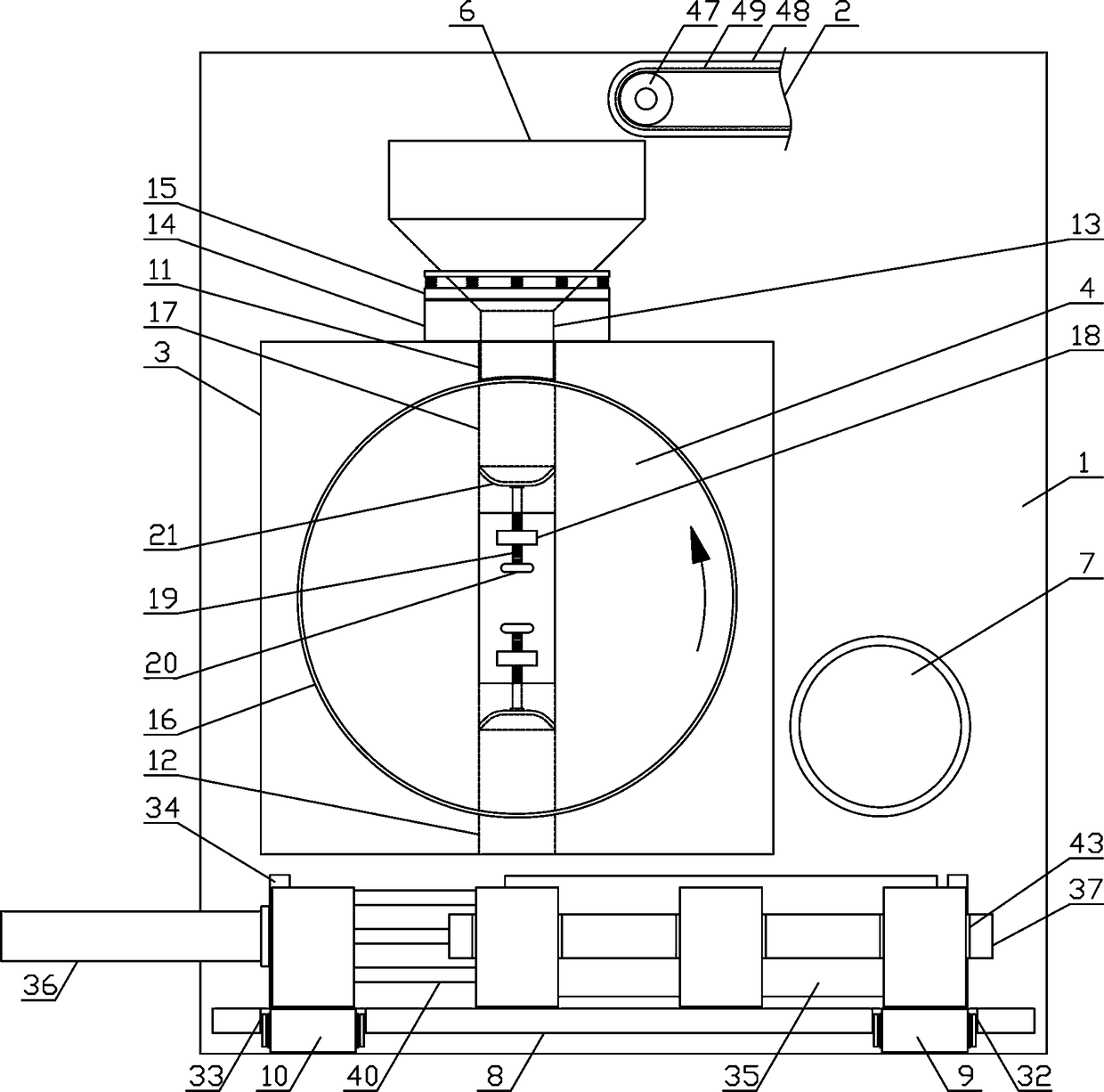

[0015] In order to further describe the present invention, the specific implementation of a granular material continuous quantitative filling mechanism will be further described below in conjunction with the accompanying drawings. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

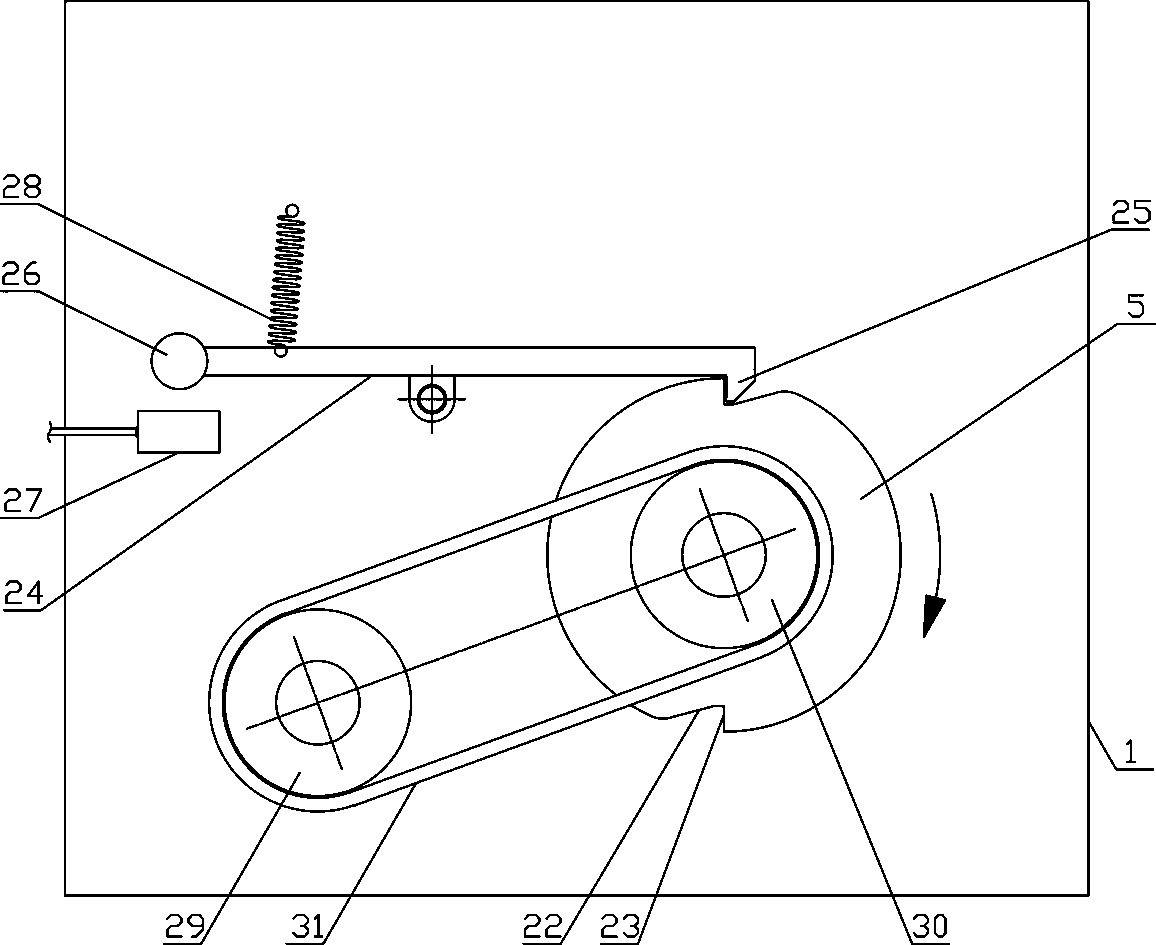

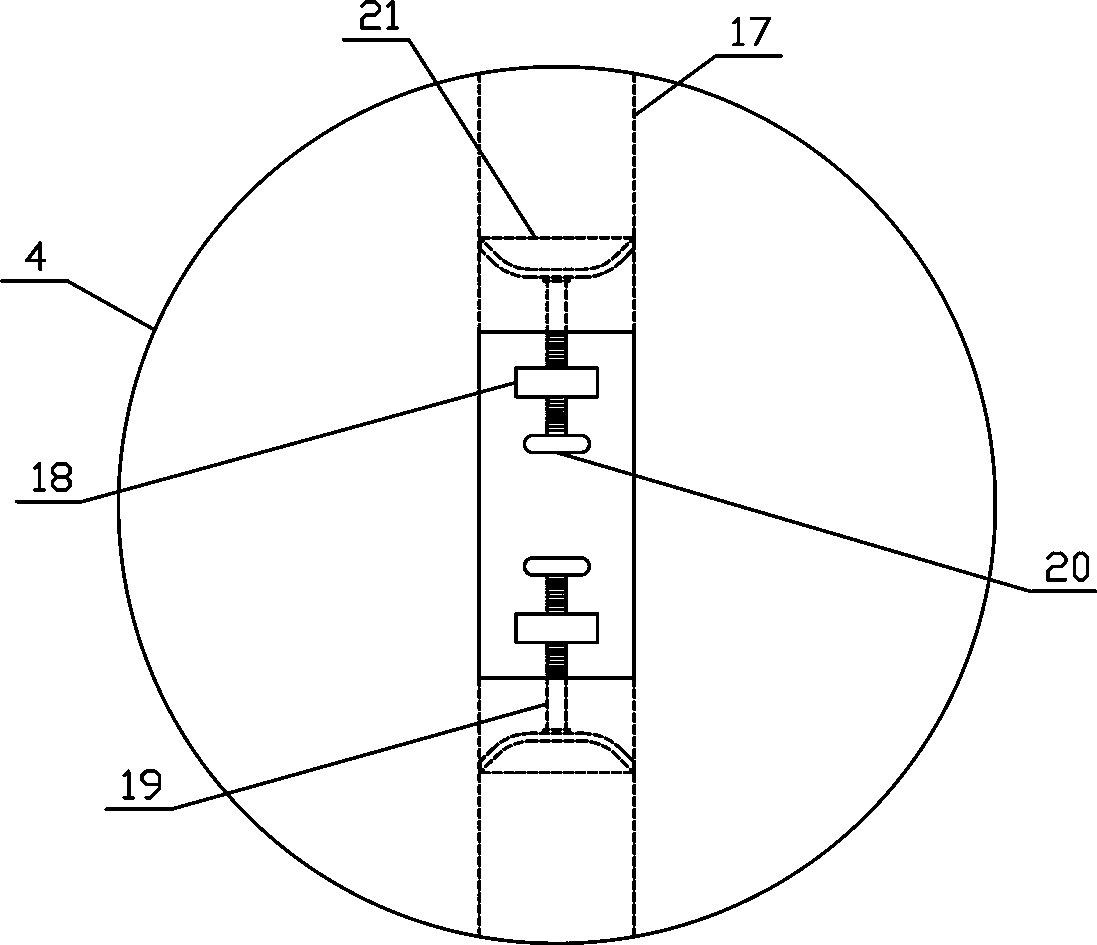

[0016] Such as figure 1 As shown, a granular material continuous quantitative filling mechanism of the present invention includes a fixed support 1, a feeding mechanism 2, a filling support 3, a rotating disc 4, a positioning turntable 5, a feeding hopper 6, a filling motor 7, and a tank guide The supporting plate 8, the tank inlet mechanism 9, the tank outlet mechanism 10 and the tank pushing mechanism, the filling bracket 3 are fixed vertically in the middle of one side of the fixing bracket 1, and the tank guide bearing plate 8 is horizontally fixed and installed on the lower side of the filling bracket 3. On the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com