Condensed cold impregnated bulk wine and production method thereof

A grape wine, cold maceration technology, applied in the field of wine making, can solve the problem of low wine quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

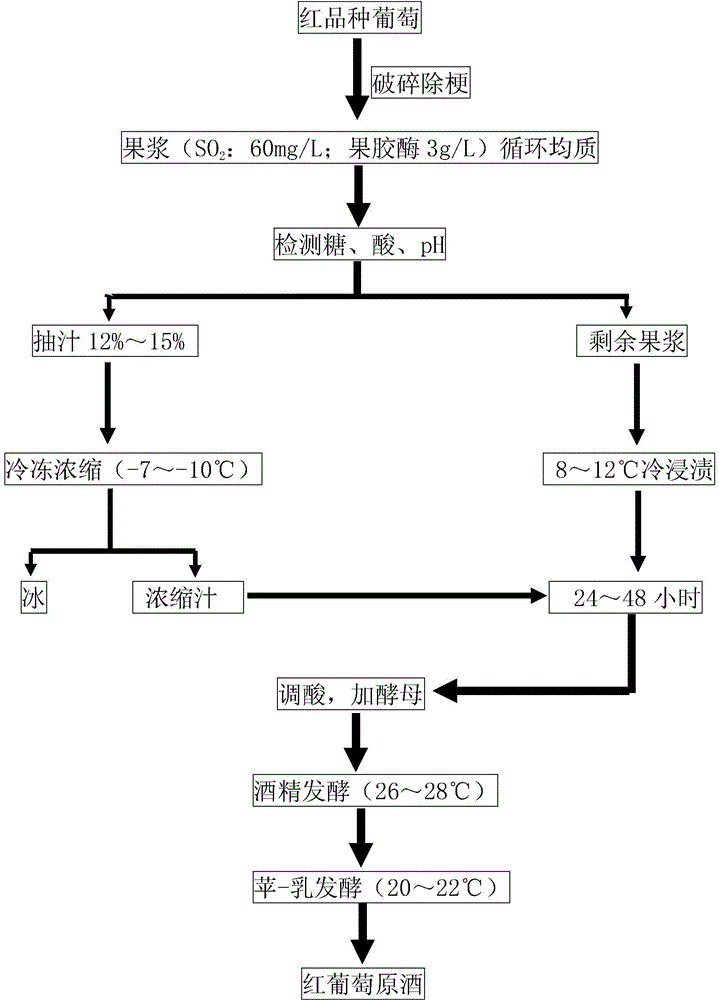

Method used

Image

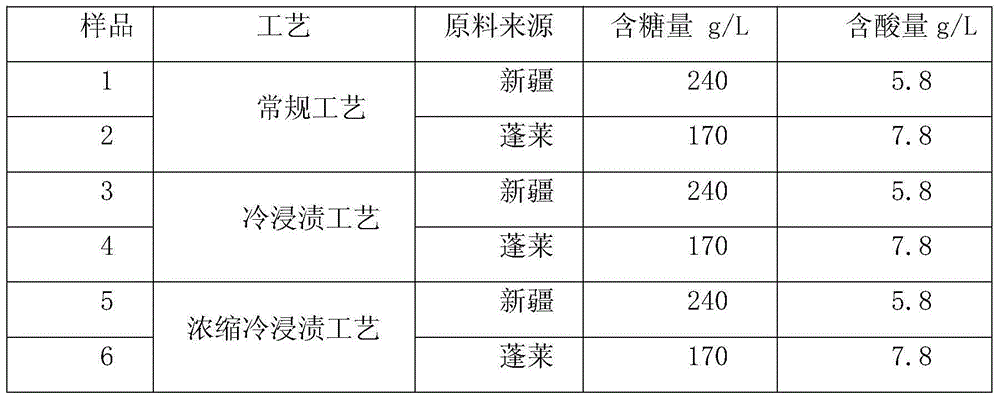

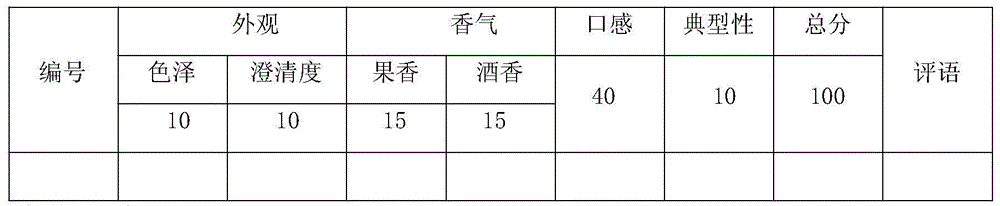

Examples

Embodiment 1

[0075] A kind of cold maceration grape original wine, is prepared by following process:

[0076] 1) Raw material selection: The raw materials of Cabernet Sauvignon grapes produced in Manas County, Xinjiang were picked in 2012, and the picked grape raw materials were strictly sorted. , rotten fruit and pesticide-contaminated fruit, the physical and chemical indicators of grape raw materials are: sugar content 240g / L, acid content 5.8g / L;

[0077] 2) Crushing and destemming: remove the fruit stems and peel the peels, put them into the fermenter, add food-grade sulfurous acid and pectinase evenly, the amount of food-grade sulfurous acid added is 60mg / L as SO2, Australia The amount of Hongsai pectinase added is 3g / L; the pump is circulated and homogenized;

[0078] 3) Separation of fruit juice: separate 12% of the grape juice by volume from the fruit pulp to the freezing tank, and cold soak the remaining fruit pulp at 8°C for 48 hours;

[0079] 4) freezing and concentrating the ...

Embodiment 2

[0085] A kind of cold maceration grape original wine, is prepared by following process:

[0086] 1) Selection of raw materials: The raw materials of Cabernet Sauvignon grapes produced in Penglai City, Shandong Province were picked in 2012, and the grape raw materials after picking were strictly sorted. The physical and chemical indicators of grape raw materials are: sugar content 170g / L, acid content 7.8g / L;

[0087] 2) Crushing and destemming: remove the fruit stems and peel the fruit, then put it into the fermenter, add food-grade sulfurous acid and pectinase evenly, and the amount of food-grade sulfurous acid added is 60mg / L as SO2, Australia The amount of Hongsai pectinase added is 3g / L; the pump is circulated and homogenized;

[0088] 3) Separation of fruit juice: separate 15% of the grape juice from the fruit pulp by volume to the freezing tank, and cold soak the remaining fruit pulp at 12°C for 24 hours;

[0089] 4) Freezing and concentrating the isolated grape juice ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com