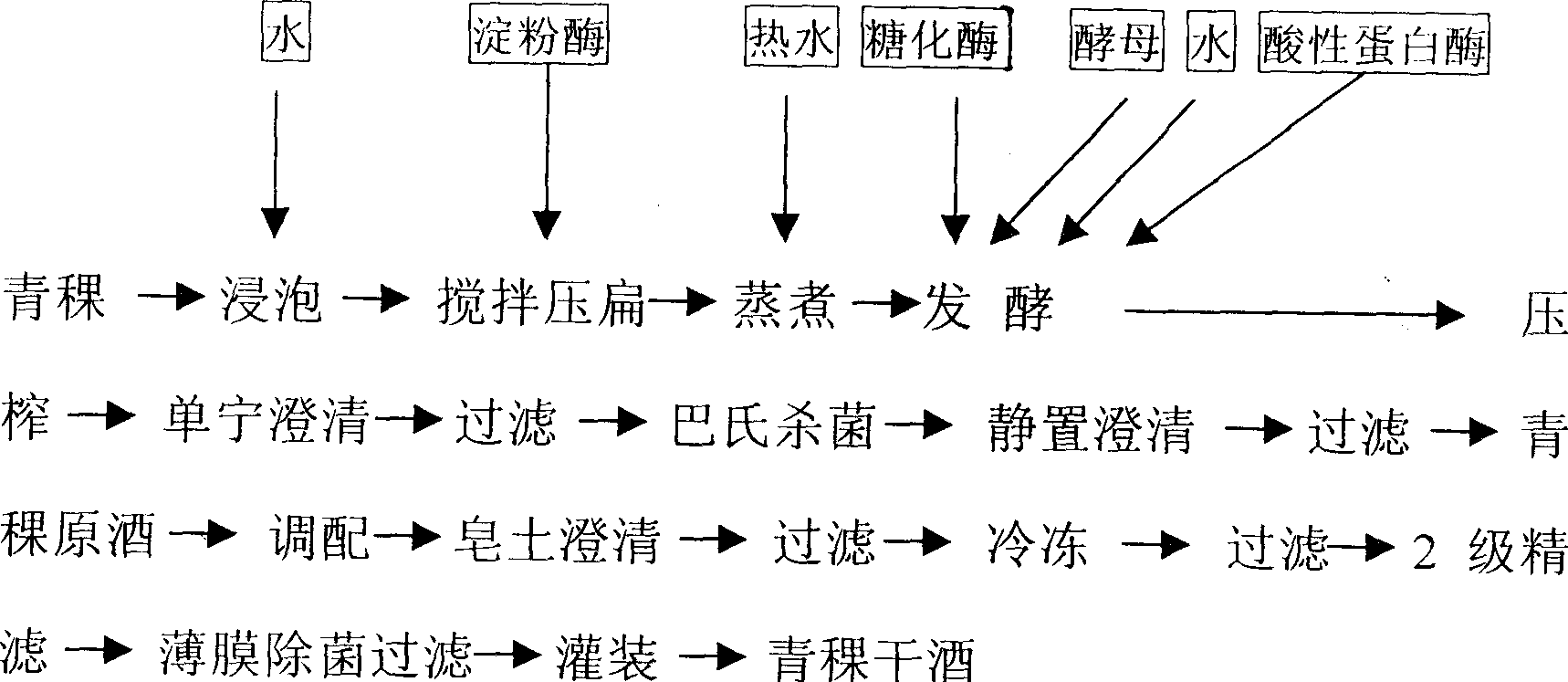

Process for preparing barley dry wine

A highland barley and evenly stirring technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of inability to produce stable, unreachable finished product alcohol, immature production technology, etc. The effect of bad odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Embodiment one: the preparation of highland barley dry liquor. Take 10KG of white highland barley with a bulk density of 780 grams per liter or more, add 20KG of water (drinking water standard), soak for about 4 days, change the water twice a day, and take the soaking degree to reach 47% as a standard. After soaking the wheat, add 30 ml of a-high-temperature-resistant amylase, stir evenly, flatten the soaked highland barley through a flattening machine, and steam the highland barley through a rice steamer until it expands and bursts. Generally 1-2 hours. Put the steamed highland barley into a 50L stainless steel fermentation tank, adjust the volume with water to a total weight of about 32 kg, add 30 grams of glucoamylase, about 14 grams of activated active dry yeast, and stir evenly. The small stainless steel fermenter is placed in a temperature-controlled fermentation room, and the ambient temperature is controlled at 20-25°C. After 30 hours, the fermentation enters ...

Embodiment 2

[0066] Embodiment two: the preparation of highland barley dry red wine. Take 10KG of purple red highland barley (the darker the color, the better) with a bulk density of 780 g / L or more, add 20KG of water (standard for drinking water), soak for about 4 days, change the water twice a day, and take the soaking degree to reach 47% as the standard . After soaking the wheat, add 30 ml of a-high-temperature-resistant amylase, stir evenly, flatten the soaked highland barley through a flattening machine, and steam the highland barley through a rice steamer until it expands and bursts. Generally 1-2 hours. Put the steamed highland barley into a 50L stainless steel fermenter, adjust the volume with water to a total weight of about 32 kg, add 30 grams of glucoamylase, about 14 grams of active dry yeast (activated), and stir evenly. The small stainless steel fermenter is placed in a temperature-controlled fermentation room, and the ambient temperature is controlled at 20-25°C. After 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com