Annealing furnace top superimposed-type fiber blanket paving method

A technology for fiber blankets and annealing furnaces, applied in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of insufficient flatness of the working surface and insufficient compression rate of fiber blankets, etc., achieving significant economic and social benefits, ensuring Sticking quality, the effect of ensuring the overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

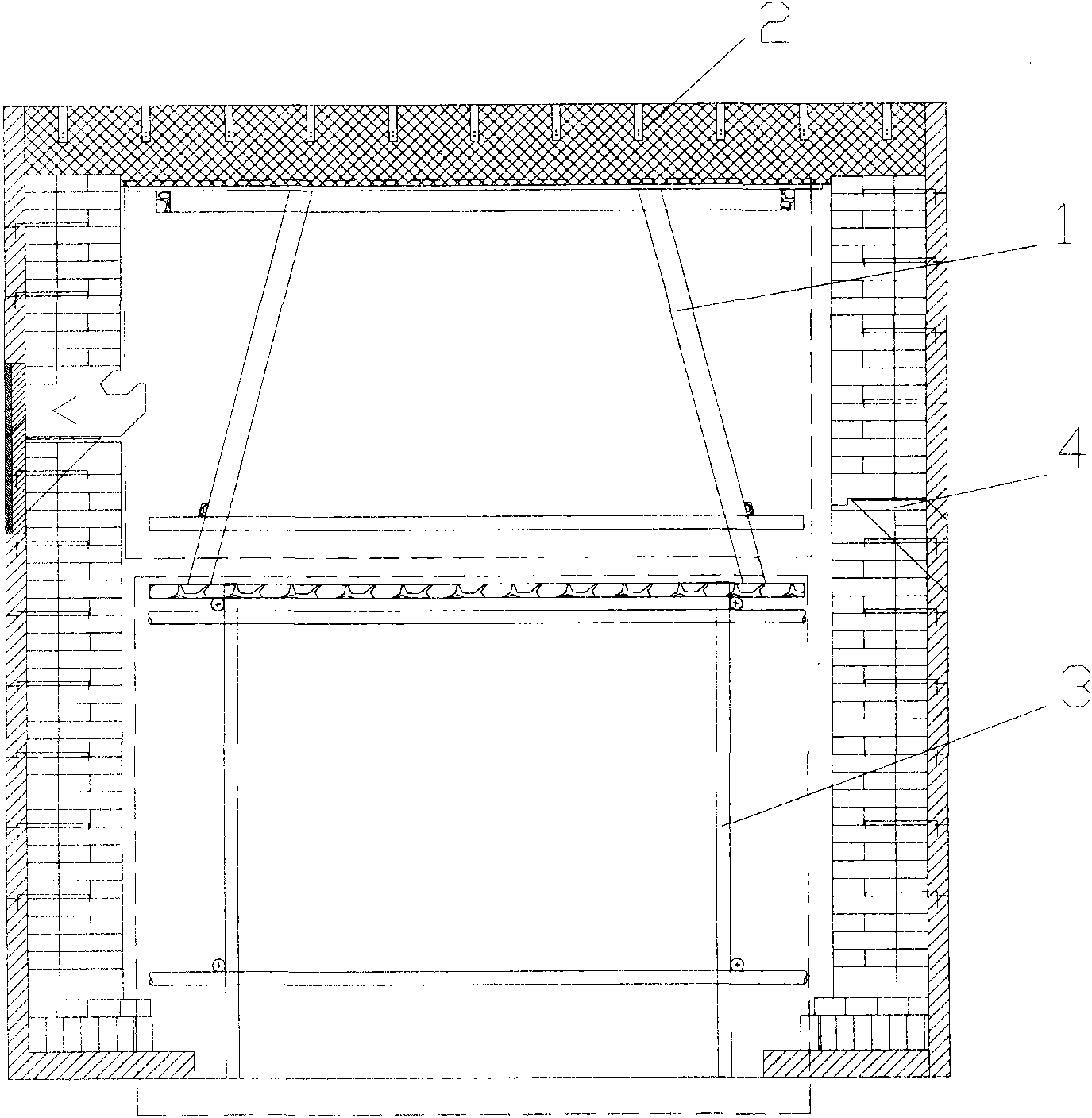

[0018] Such as figure 1 Shown: Before laying the fiber blanket, make a model mold 1 according to the net width, height, and modulus size of the fiber blanket assembly (generally 300mm). The surface of the mold 1 must be glazed (smooth). The width of the mold 1 is: the module size of the fiber blanket assembly (300mm) + 50mm; the length is: the net width of the furnace - (30mmX2); the height is: the total height of the furnace - the height of the operating platform - the thickness of the fiber blanket 2 on the furnace top - 30mm.

[0019] Construction steps:

[0020] Set up a light workbench 3 (easy to move) under the furnace roof paving, workbench size = length X width X height = 3000mmX (clean width of the furnace - 100X2) X (total height of the furnace - height of the mold - thickness of fiber blanket on the furnace top - 30mm) ;

[0021] Below the module of the furnace top fiber blanket group 2, the mold 1 is supported on the mobile workbench 3, and the wood under the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compression ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com