Non-contact displacement sensor self-recovery impact resistance device and evaluation method thereof

A displacement sensor, non-contact technology, applied in the field of displacement sensors, can solve the problems of cumbersome use process, long-distance transmission of measurement signals susceptible to interference, weak adaptability to large displacement, etc., and achieve the effect of attenuating impact destructive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

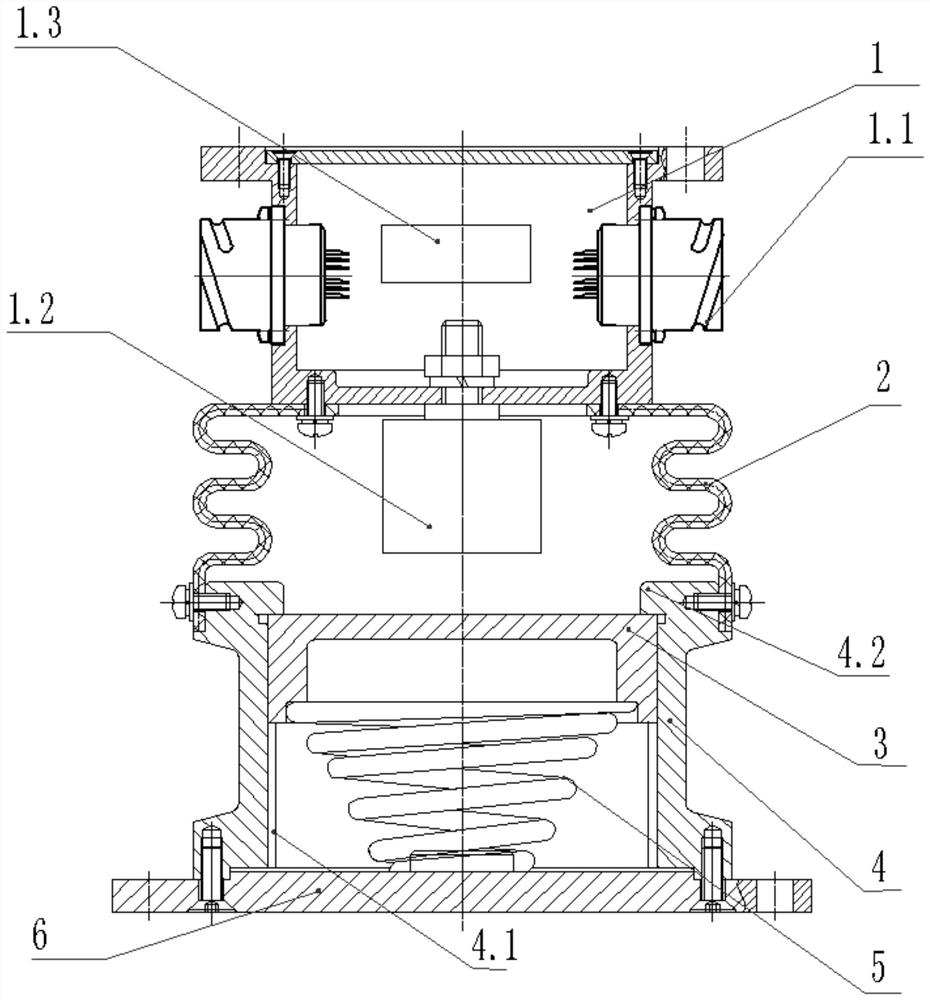

[0031] As an embodiment, the displacement sensor body assembly 1 includes a housing, an electrical connector 1.1, a sensor probe 1.2, and a signal processing module 1.3; the electrical connector 1.1 is disposed on both sides of the outer casing, the signal processing module 1.3 is set Inside the housing, the sensor probe 1.2 is disposed under the lower surface of the outer casing. The maximum use of the capsule bellows 2 can be adapted to the limit displacement of the sensor probe 1.2 and the detecting plate 3 when the maximum modification is adapted to the large impact;

[0032] As an embodiment, the restricted housing 4 is vertically disposed with a straight rail 4.1, and the detecting plate 3 can move up and down along the guide rail 4.1. The upper end surface of the restricted housing 4 is in contact with the probe plate. The linear guide 4.1 of the inner wall of the limit housing 4 has a motion guide function, and can avoid the detection plate 3 tilt during the impact process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com