Bionic support buffer structure and non-pneumatic tires

A technology of non-pneumatic tires and buffer structures, applied in non-pneumatic tires, tire measurement, tire parts, etc., can solve the problem that the support buffer structure cannot resist the influence of linear acceleration and angular acceleration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

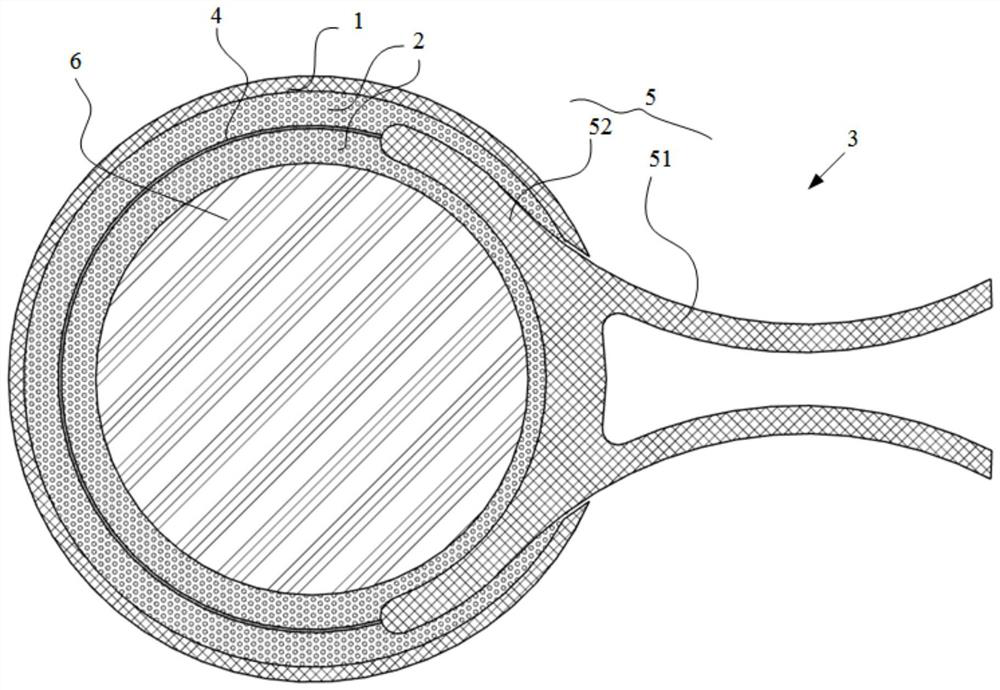

[0046] In the embodiment of the present invention, such as Figure 1-5 As shown, the bionic support buffer structure includes:

[0047] Housing 1, the housing 1 is formed with a receiving chamber with an opening;

[0048] The support buffer assembly 3, the support buffer assembly 3 includes a receiving part and a supporting part, the receiving part is hollow and located in the receiving cavity, the supporting part extends out of the receiving cavity through the opening of the housing, And used to connect external components;

[0049] a buffer body 6, the buffer body 6 is located in the receiving portion; and

[0050] The cooling buffer 2 is provided between the outer wall of the buffer body 6 and the inner wall of the receiving part, and between the inner wall of the housing 1 and the outer wall of the receiving part.

[0051] In a specific implementation process, the part of the support buffer assembly 3 inside the casing 1 is the receiving part, and the part outside the cas...

Embodiment 2

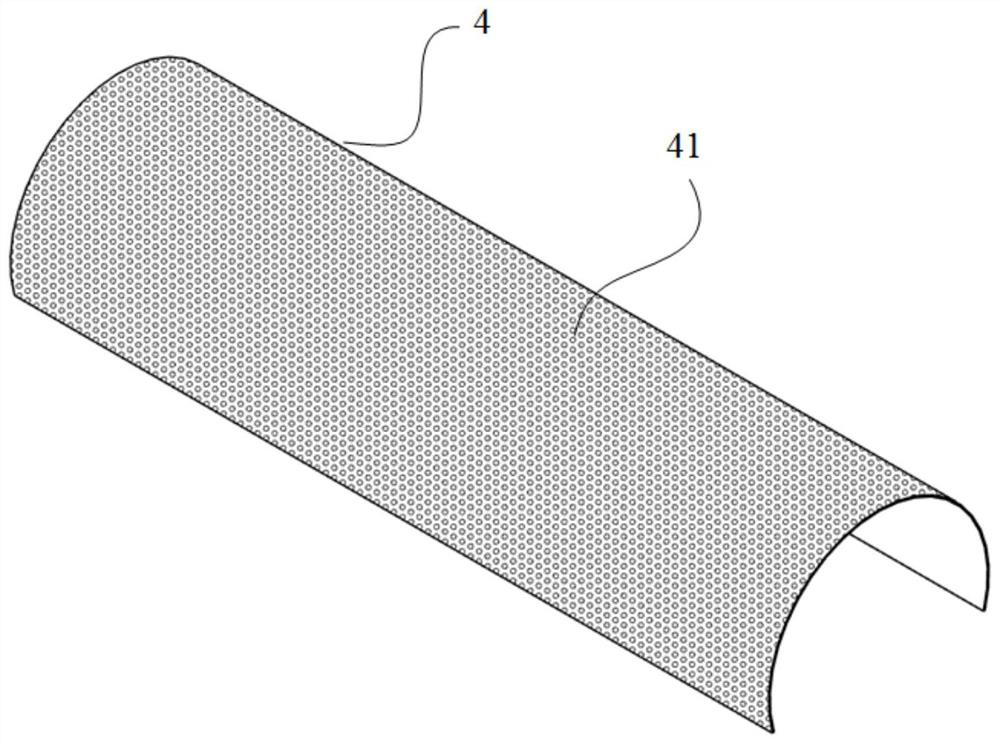

[0066] On the basis of the above embodiments, the housing 1 in this embodiment has a spherical structure, and accordingly, the buffer body 6 is also configured as a spherical structure. The cooling buffer 2 is filled between the buffer body 6 and the housing 1, and the cooling buffer 2 is embedded with a telescopic belt 4, and the telescopic belt 4 wraps half of the outer side of the buffer body 6. Of course, there is also a cooling buffer between the two. piece 2. The other half of the structure of the buffer body 6 is wrapped by one end of the support member 5 , and the cooling buffer member 2 is filled between the two, and the stretchable belt 4 and the support member 5 wrap the entire buffer body 6 . The other end of the support member 5 extends out of the casing 1 to receive and transmit impact energy.

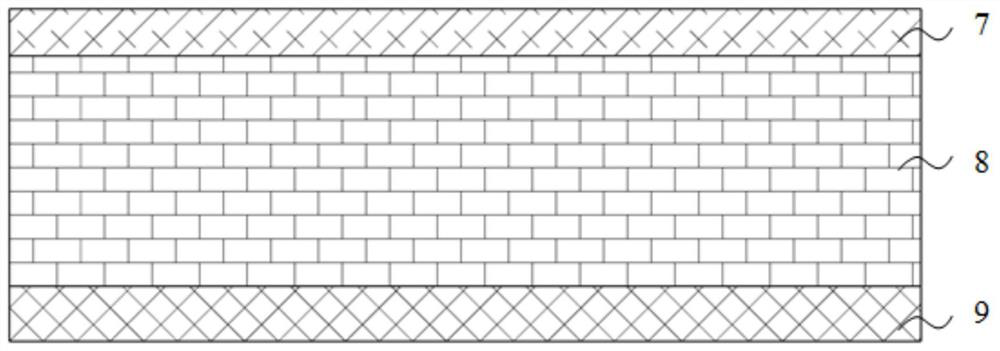

[0067] The present invention also proposes a non-pneumatic tire, such as Figure 6-10 As shown, the non-pneumatic tire includes the bionic support and buffer structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com