Grating ruler installation device and method

A technology for installing devices and grating rulers, which is applied in the direction of optical devices, measuring devices, instruments, etc., can solve the problems of grating reading head not being able to read the grating ruler, movement path error, signal loss, etc., to reduce errors and movement paths Consistent, smooth paste results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

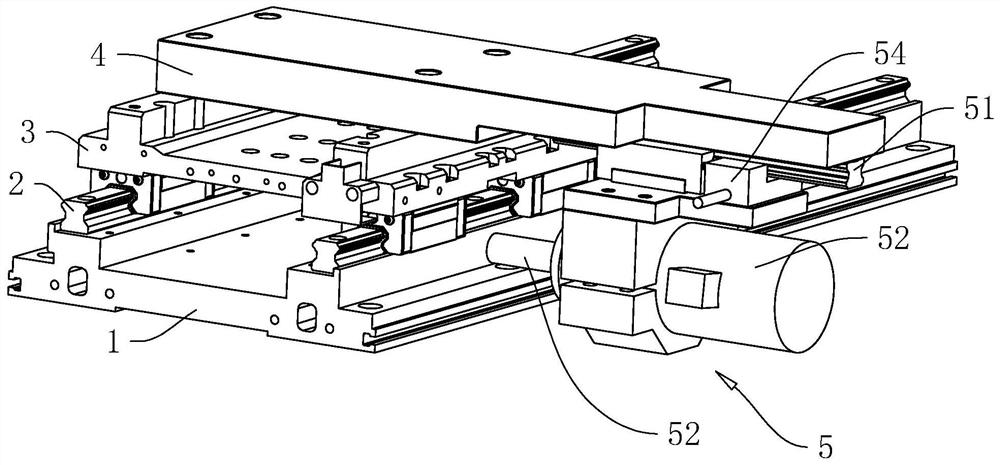

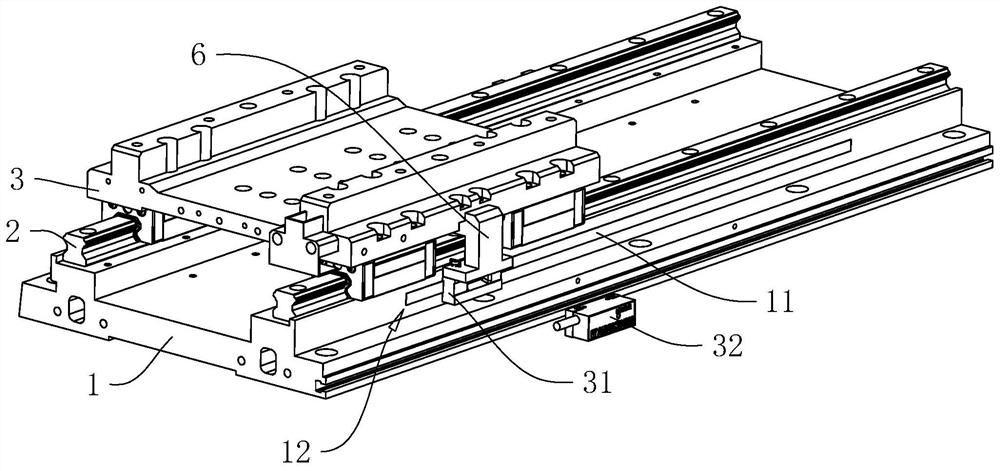

[0045] Embodiment 1, with reference to figure 1 The grating ruler installation device includes a base 1, a guide rail 2, a platform plate 3 and a first connecting frame 4, two guide rails 2 are provided, and the two guide rails 2 are arranged on the base 1 in parallel and at intervals; the platform platform 3 is slidably connected to the base 1 through the guide rail 2. In this embodiment, the object to be detected will be placed on the platform 3 and move along the length extension direction of the guide rail 2 through the platform 3, so as to be detected The purpose of detecting the linear displacement change of the object, in addition, in other embodiments, the guide rail 2 can also be an arc-shaped guide rail, so as to achieve the purpose of changing the angular displacement of the detected object.

[0046] refer to figure 1 and figure 2 , because when the guide rail 2 is straight or arc-shaped, the installation method of the grating ruler 11 is the same, so the follow-...

Embodiment 2

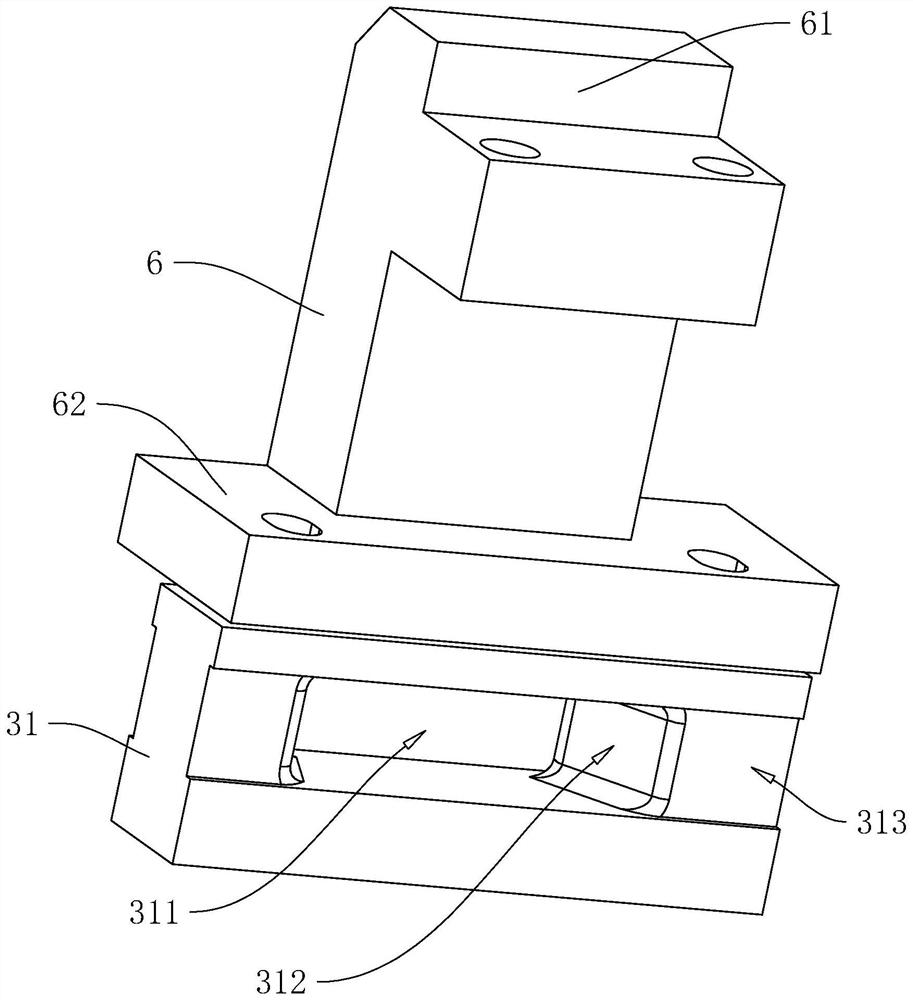

[0055] Embodiment 2, with reference to Figure 4 and Figure 5 The difference from Embodiment 1 is that the two second connecting ends 62 are provided with first connecting holes 621, and the ruler block 31 is provided with a second connecting hole 314 coaxially communicating with the first connecting holes 621, And the first connecting hole 621 and the second connecting hole 314 are provided with a connecting piece 7 that fixes the ruler block 31 and the second connecting frame 6. Specifically, the connecting piece 7 includes two connecting plates 71, a support bar 72, a push The rod 73 and the blocking block 74, the connecting plate 71 is in the shape of a tile, and the connecting plate 71 is passed through the inner circle of the second connecting hole 314. In this embodiment, the first connecting hole 621 is close to the second connecting hole 314 The inner wall of one end is provided with a chute 316 with a T-shaped cross section, and the end of the connecting plate 71 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com