Mold replacing device of injection mold

A technology for injection molds and molds, which is applied in the field of mold changing devices for injection molds. It can solve the problems of low mold loading efficiency, easy installation errors, and long labor time, and achieves the effects of convenient operation, less error, and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

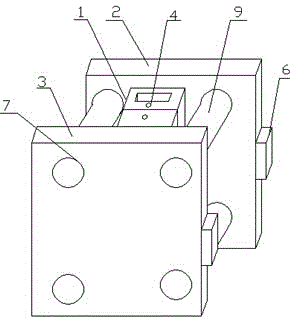

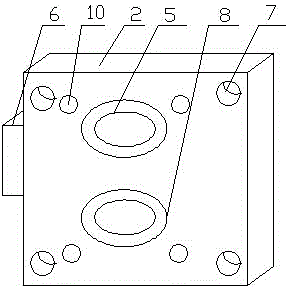

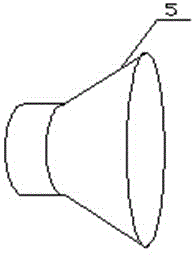

[0011] The invention provides a mold changing device for an injection mold, comprising a mold 1, a front mold backing plate 2, a rear mold backing plate 3, a suspension ring 4, a vacuum sucker 5, a vacuum pump 6, a through hole 7, an electromagnetic heating pipeline 8, bolts 9, Mold correction device 10, the top of the mold 1 is provided with a suspension ring 4, the front mold backing plate 2 and the rear mold backing plate 3 are provided with a vacuum chuck 5, a through hole 7, an electromagnetic heating pipeline 8, an infrared sensor 9 and Die correction device 10, a vacuum pump 6 is installed on one side of the front mold backing plate 2 and the back mold backing plate 3, the back of the mold 1 is connected with the vacuum chuck 5, the vacuum chuck 5 is connected with the vacuum pump 6, and the vacuum An electromagnetic heating pipeline 8 is arranged on the outside of the suction cup 5 , and the bolt 9 connects the front mold backing plate 2 and the back mold backing plate ...

Embodiment 2

[0013] When disassembling the old mold, the bolt 9 passing through the through hole 7 is disassembled, the front mold backing plate 2 and the back mold backing plate 3 can be separated, the vacuum pump 6 is turned off, and the abrasive tool 1 is connected to the front mold backing plate 2 and the back mold The backing plate 3 is separated, and the old mold 1 can be hoisted by the crane through the suspension ring 4.

[0014] When installing a new mold, the crane hangs the new mold 1 between the front mold backing plate 2 and the rear mold backing plate 3 through the lifting ring 4, starts the electromagnetic heating pipeline 8 to preheat the mold 1 before processing, and the mold corrector 10 Correct the deviation of the mold 1 with an error in the placement position, start the vacuum pump 6, and the vacuum suction cup 5 will work to suck the mold 1 tightly on the surface of the front mold backing plate 2 and the rear mold backing plate 3. After that, the operator puts the bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com