Tube rolling borer for firework paper tube rolling machine

A technology of reeling machine and reel, which is applied in the directions of fireworks, offensive equipment, weapon types, etc., can solve the problems of affecting the launching effect and the inner cavity of the cylinder is not smooth, so as to achieve the effect of smooth inner wall and ensure the launching effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

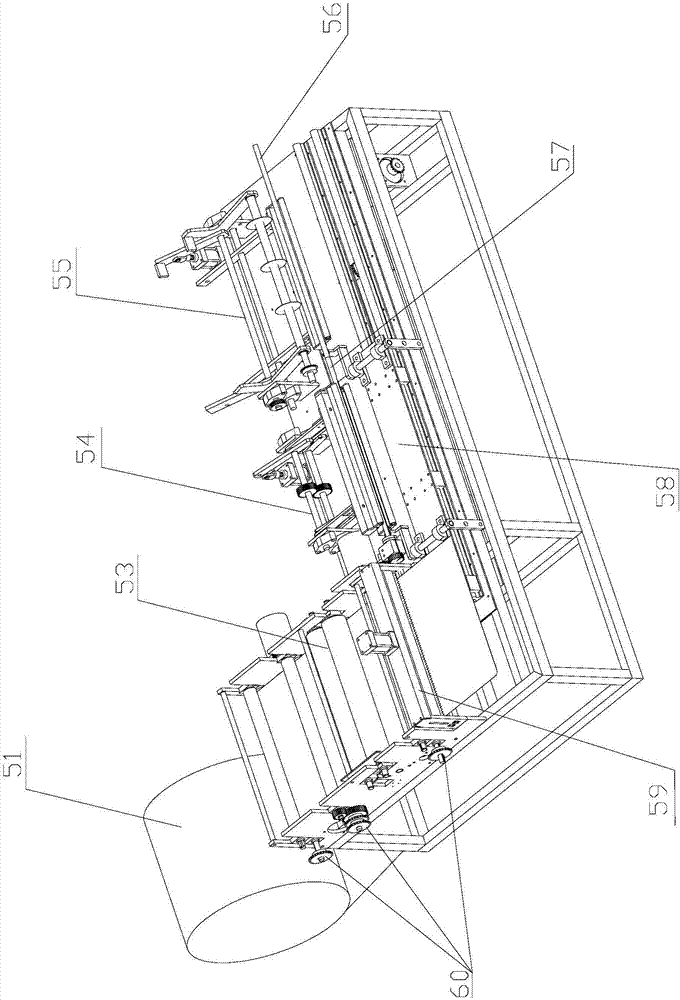

[0014] Embodiment 1: see attached Figure 1-2 , reflecting a specific structure of the present invention, the reel machine of the firework paper tube includes a base paper roll 51, a gluing mechanism 53, and a paper cutting mechanism 59 arranged in sequence along the paper feeding direction, and three groups of paper feed roller groups 60 hold the base paper The paper of the roll 51 is sent to the paper cutting mechanism 59, which also includes a reel mechanism 54 and a bobbin mechanism 55 arranged side by side with the paper cutting mechanism 59, and a rewinding mechanism 58 and the reel mechanism 54 are arranged side by side.

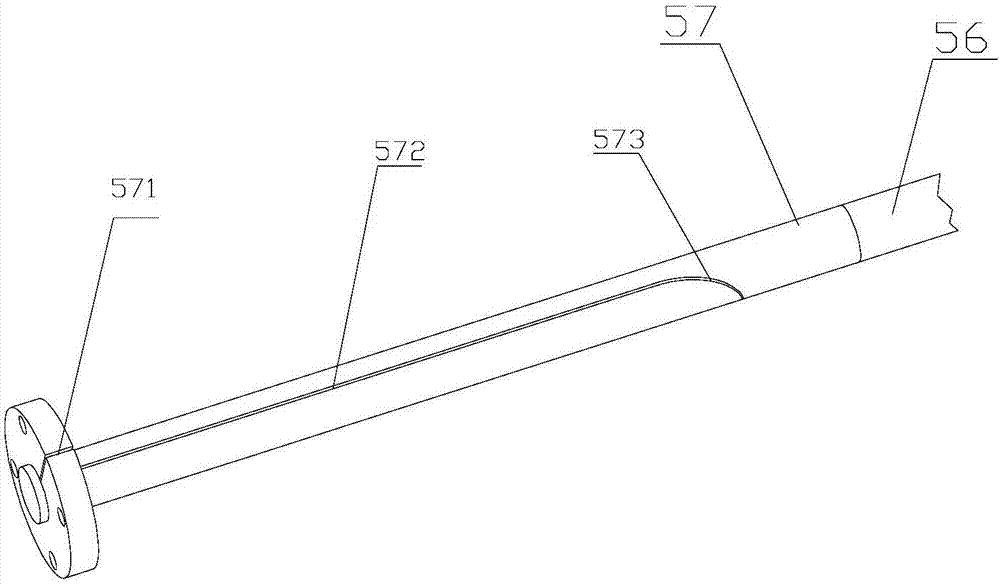

[0015] The reel drill 57 of the reel mechanism 54 is provided with a paper insertion gap, and the paper insertion gap is composed of a straight section 572 and a guide arc section 573: the straight section 572 is distributed along the axial direction of the drill body of the reel drill 57; The arc section 573 is close to the cylinder cutting drill 56 ...

Embodiment 2

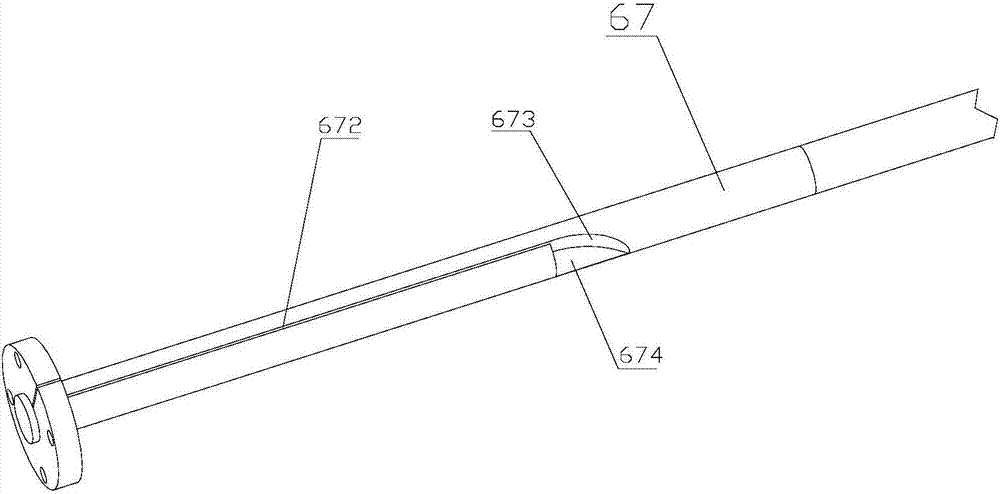

[0018] Example 2: see image 3 , The solid cylinder reel 67 is provided with a paper insertion gap, and the paper insertion gap is composed of a straight line segment 672 and a guiding arc segment 673 . The difference from Embodiment 1 is that a notch 674 is provided at the end of the guiding arc section 673 . This makes the process of the paper head withdrawing from the gap and evenly pasted and attached to the inner wall of the paper tube smoother.

Embodiment 3

[0019] Embodiment 3: see Figure 4 , The reel brazing 77 is provided with a paper insertion gap, and the paper insertion gap is composed of a straight line segment 772 and a guiding arc segment 773, and a notch 774 is provided at the end of the guiding arc segment 773. The difference from Embodiment 2 is that the reel drill 77 is a hollow cylinder. The purpose of the invention can also be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com