A hand-held glass sealing strip sticking tool

A glass sealing and hand-held technology, which is applied in the field of hand-held glass sealing strip pasting tooling, can solve the problems of high cost, space-occupied sealing strip, easy bending, poor consistency, etc., and achieve the effect of convenient operation, not easy to bend, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

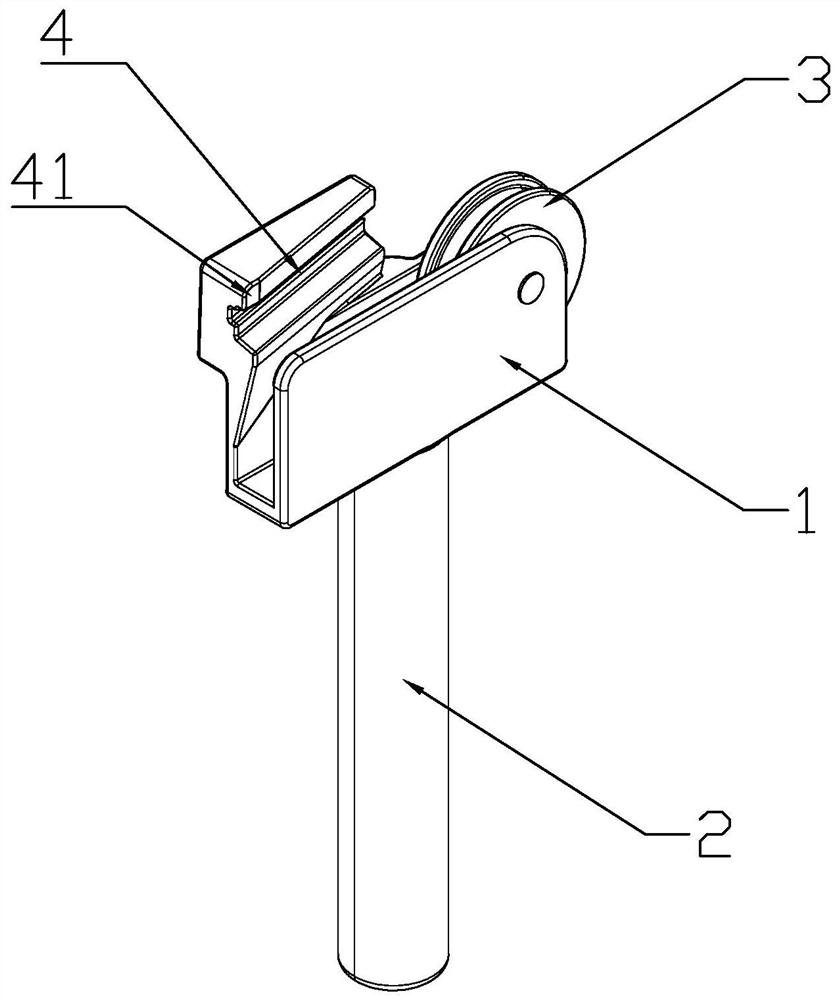

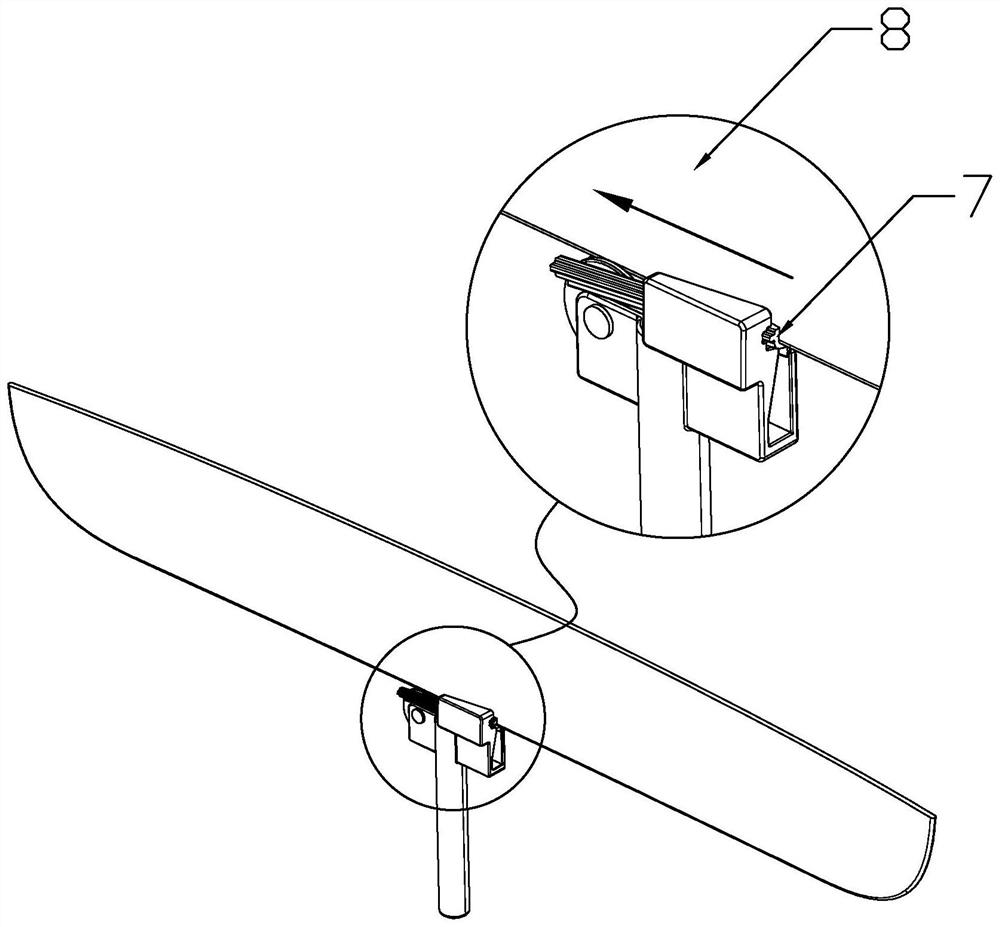

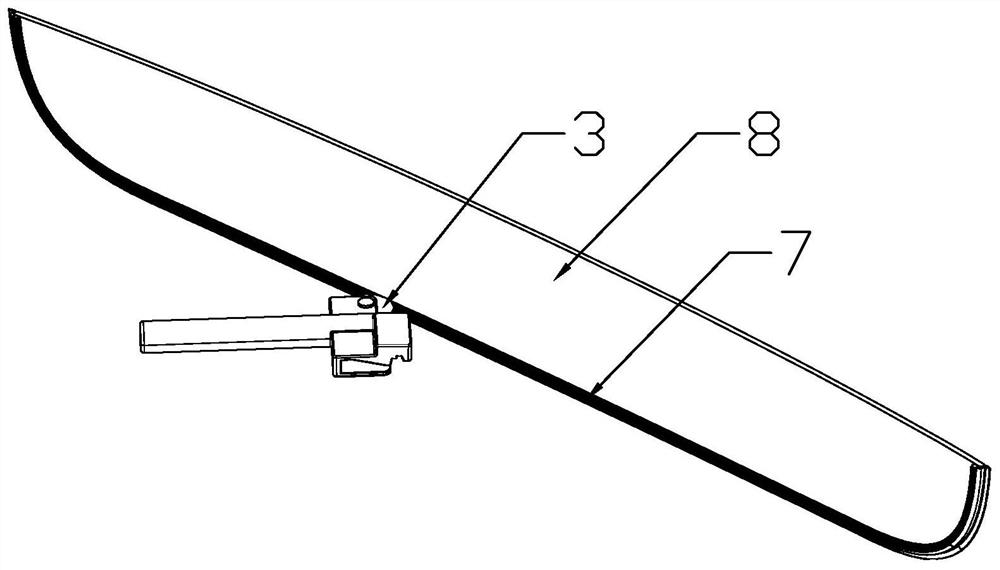

[0033] like figure 1 As shown, a hand-held glass sealing strip sticking tool includes a bracket 1 and a handle 2 , the bracket 1 has a U-shaped groove structure as a whole, and the handle 2 is arranged at the bottom of the bracket 1 . A roller 3 for rolling along the edge of the glass is rotatably connected to the U-shaped groove of the bracket through rivets. The tangential direction of the roller 3 is consistent with the extending direction of the U-shaped groove. A side wall of the bracket 1 extends upward to form a pre-pressing portion, and the pre-pressing portion is provided with an installation groove 4 for accommodating the sealing strip, the opening of the installation groove 4 faces the U-shaped groove, and the cross-sectional shape of the installation groove 4 is adapted to the cross-sectional shape of the sealing strip. An angle is formed between the extending direction of the installation groove 4 and the tangential direction of the roller 3. The installation groo...

Embodiment 2

[0036] like Figure 4 As shown in the figure, a hand-held glass sealing strip sticking tool, its structure is roughly the same as that of Example 1, the difference is that it also includes a sealing strip fixing structure, such as Figure 5 As shown, the sealing strip fixing structure includes air bags 42 disposed on the groove walls on both sides of the installation groove 4 and an inflation and deflation device communicating with the air bags 42 . like Image 6 As shown, the inflating device includes a cylinder 5 that communicates with an airbag 42, a piston 51 is connected in the cylinder 5 through a tension spring 52, the airbag 42 is communicated with a cavity provided with a tension spring in the cylinder 5, and the piston 51 extends to the outside of the cylinder 5 to form a stopper The wind plate 53 is provided with a fan 6 on one side of the wind shield 53 . The fan 6 is connected to the roller 3 through a gear set as a speed increasing device. A cylindrical air gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com