Linear guide device

A technology of linear guide device and guide surface, applied in the direction of linear motion bearings, bearings, bearing components, etc., can solve the problem of difficult to predetermine the precise installation position of guide rails

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

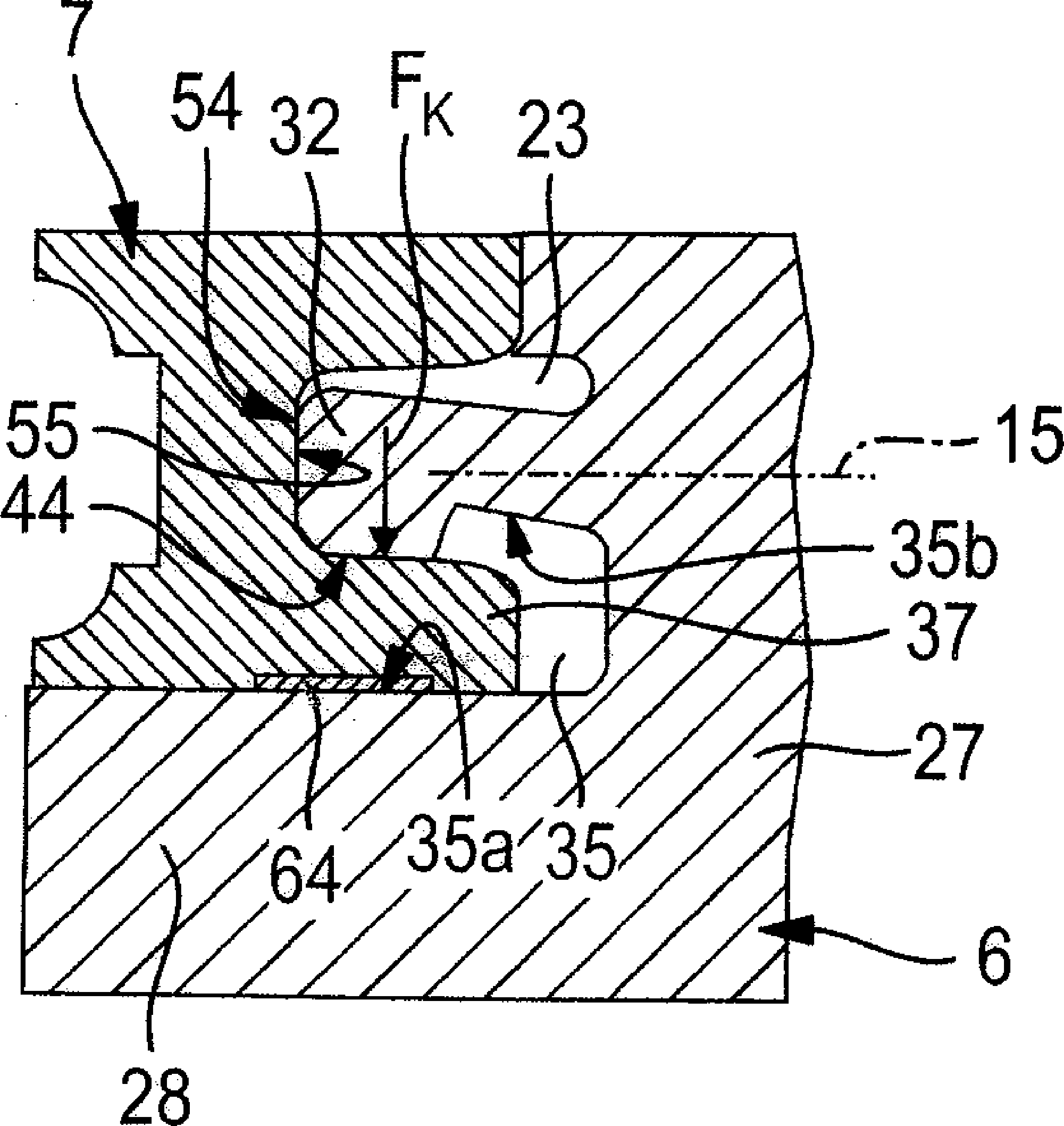

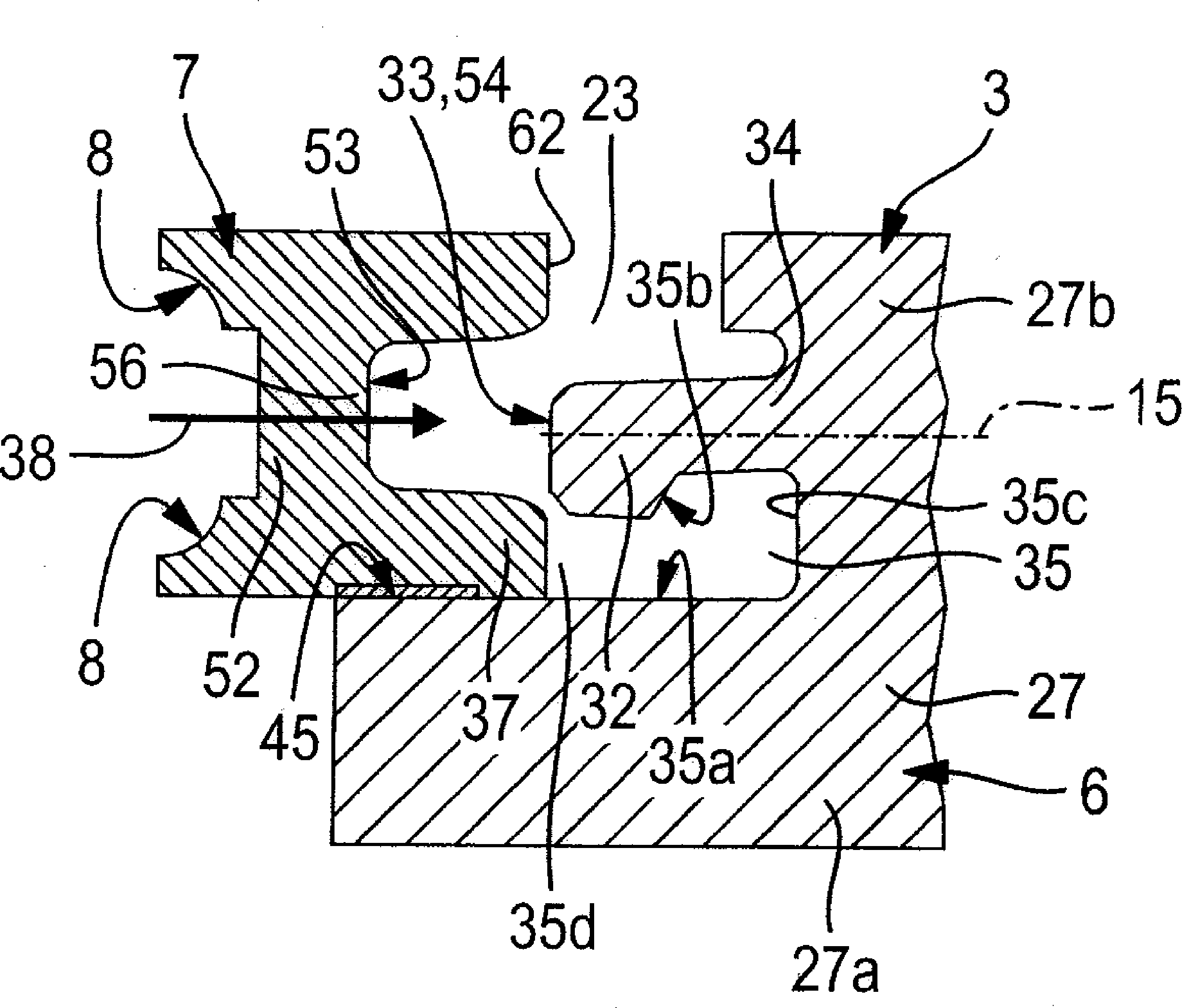

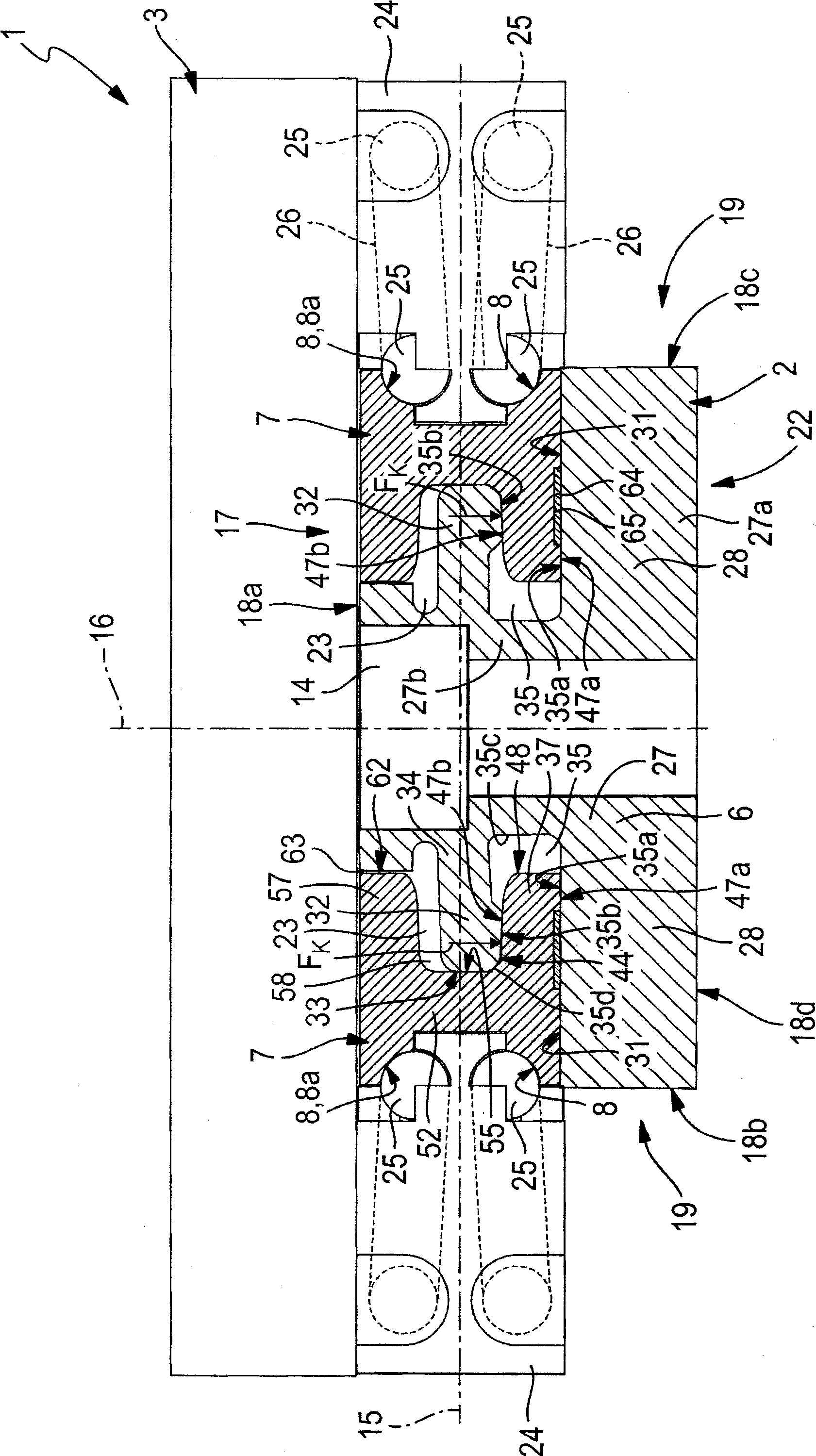

[0027] figure 1 and figure 2 A linear guide is illustrated generally designated with the reference number 1 , comprising a guide unit 2 and a guide element 3 which is designed in the manner of a slide and can therefore also be referred to as a guide slide. The guide unit 2 has a longitudinal shape with a longitudinal axis 4 , wherein a guide element 3 is movably mounted on the guide unit 2 for carrying out a linear movement 5 directed in the same direction as the longitudinal axis 4 .

[0028] Preferably, the guide unit 2 contains a one-piece carrier body 6 made of metal, wherein an aluminum material is particularly recommended as material or raw material. Furthermore, the guide unit 2 contains two guide rails 7 , which are fastened to the carrier body 6 in a non-positive manner in the region of the crimp connection and each have at least one guide surface 8 for linearly guiding the guide element 3 .

[0029] The carrier 6 has a linear extension, likewise each of the two ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com