Chopstick grinding device

A grinding and chopsticks technology, applied in grinding/polishing safety devices, grinding/polishing equipment, grinding machines, etc., can solve the problems of low processing efficiency and low dimensional accuracy of chopsticks embryos, and achieve the effect of ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments of the description:

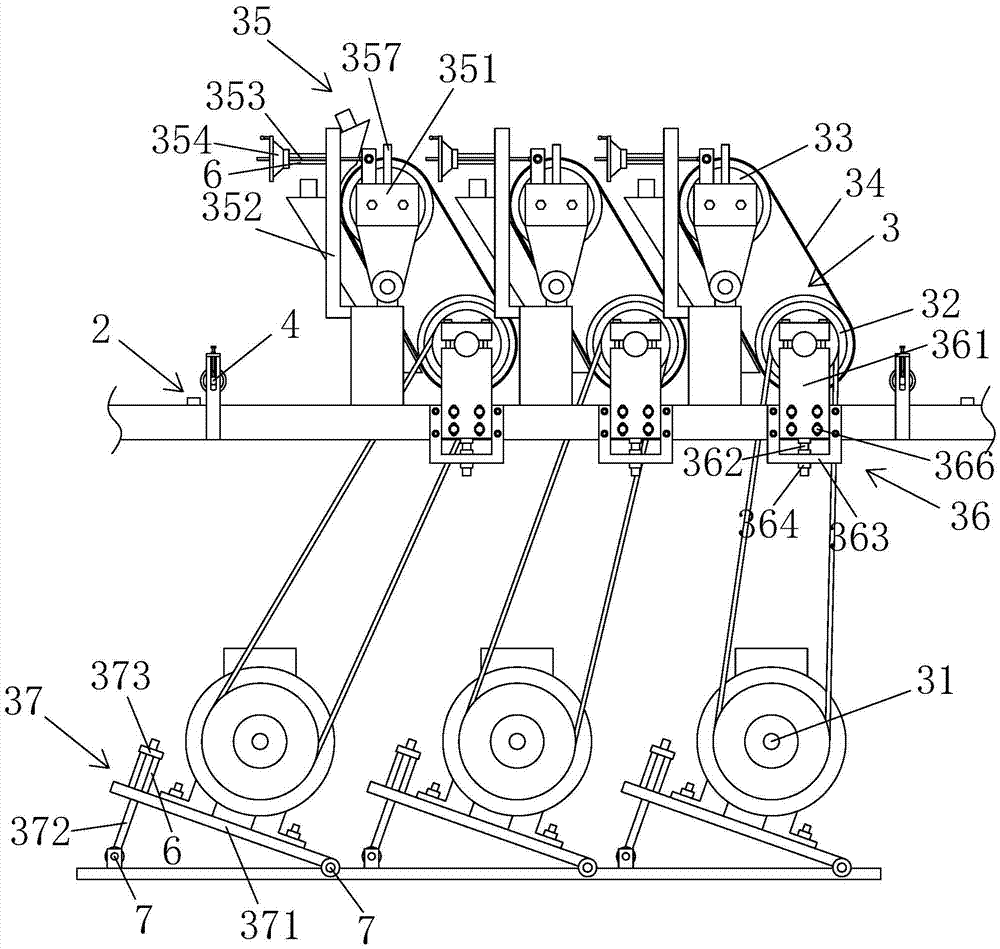

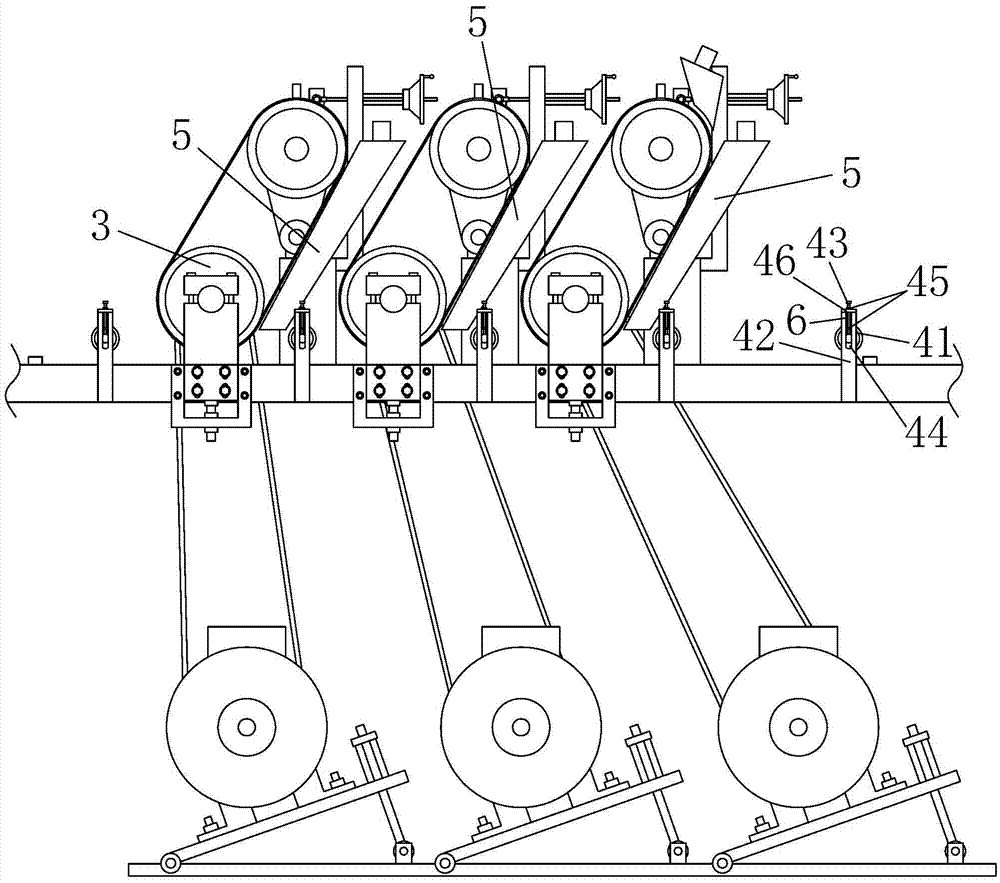

[0022] Such as Figures 1 to 7 Shown is a schematic diagram of an embodiment of a chopsticks grinding device provided by the present invention.

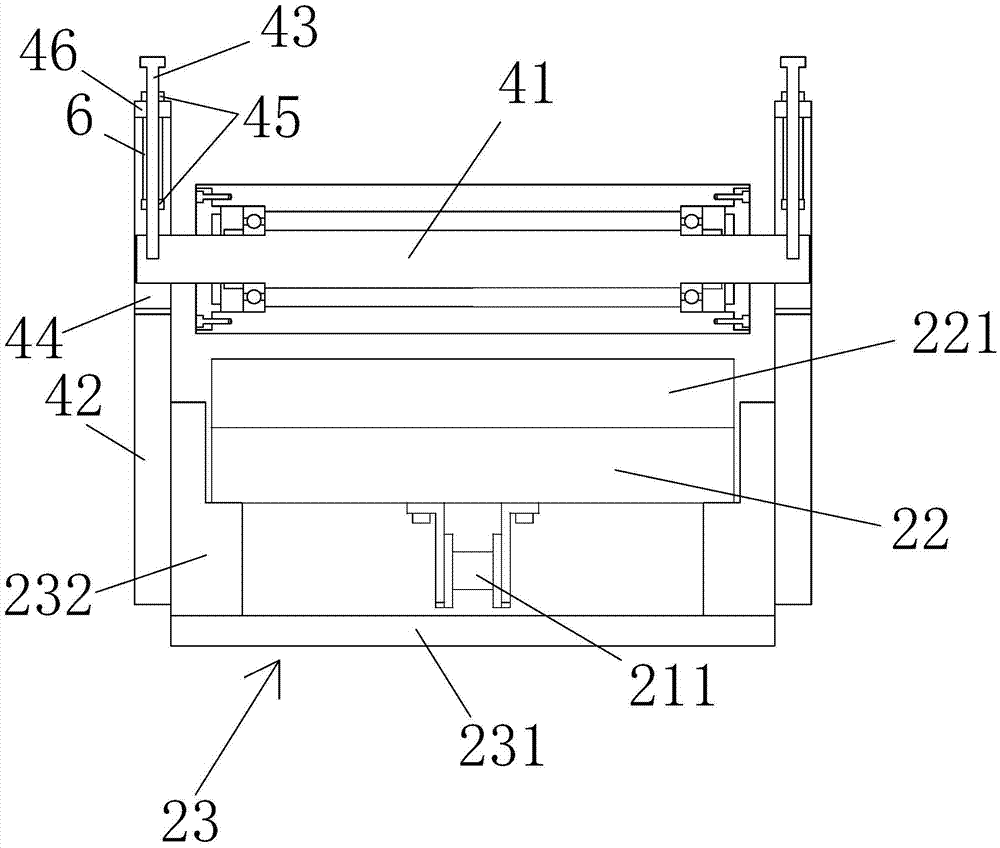

[0023] A chopsticks grinding device comprises a frame 1, a conveying assembly 2 arranged on the frame 1, and more than one grinding assembly 3 arranged above the conveying surface of the conveying assembly 2 and along the conveying direction.

[0024] It also includes more than three chopsticks pressing assemblies 4 arranged at intervals along the conveying direction of the conveying assembly 2 and the interval distance is smaller than the length of the chopsticks; the grinding assembly 3 is arranged between two adjacent chopsticks pressing assemblies 4 .

[0025] The setting of the spacing between the chopsticks pressing assemblies 4 can effectively ensure that each chopst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com