Hand-held type working machine

A working machine, hand-held technology, applied in the direction of machine/engine, mechanical equipment, engine components, etc., to achieve the effect of simple structure, reduced vibration transmission, and reduced vibration transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

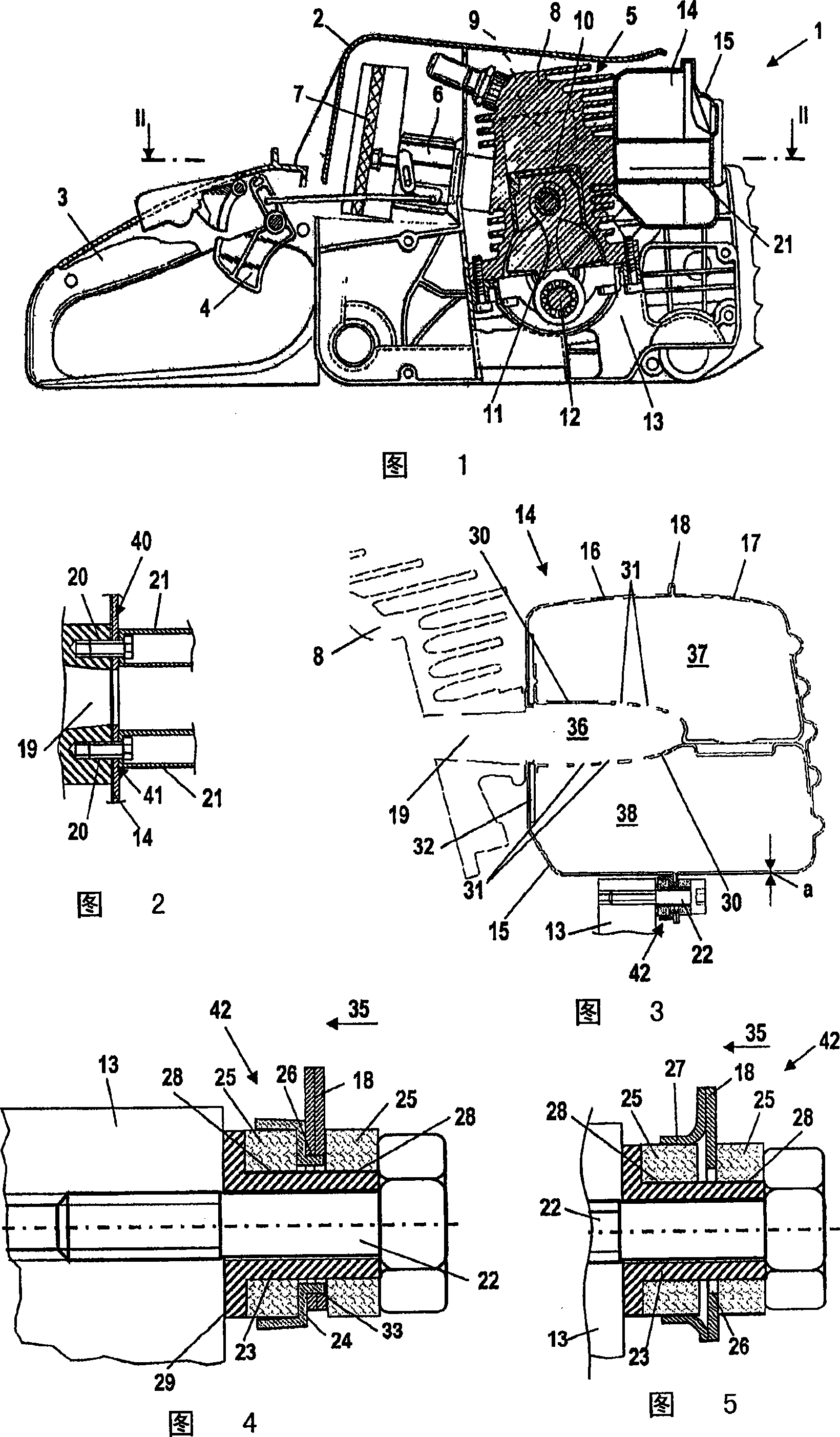

[0020] The work machine shown in FIG. 1 is a power saw 1 . The power saw 1 has a housing 2 on which a rear handle 3 is fastened. The rear handle 3 has a gas lever 4 for operating an internal combustion engine 5 arranged in the housing 2 . The internal combustion engine 5 is a single-cylinder two-stroke engine and contains an air filter 7 which is connected to the internal combustion engine 5 via a carburetor 6 . The intake duct formed in the carburetor 6 opens into the crankcase 13 of the internal combustion engine 5 . The internal combustion engine 5 has a cylinder 8 in which a combustion chamber 9 is formed. A piston 10 is accommodated in the cylinder 8 so as to move back and forth. The piston 10 drives a crankshaft 12 , which is rotatably accommodated in a crankcase 13 , via a connecting rod 11 . The crankshaft 12 drives a tool, not shown in FIG. 1 , ie a saw chain, in rotation. An exhaust muffler 14 with a housing 15 is arranged on the internal combustion engine 5 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com