Method for assembling lining plates of multi-cylinder cone crusher

A technology of cone crusher and movable cone liner, which is applied in the direction of assembly machine, metal processing equipment, welding equipment, etc., which can solve the problems of inability to judge liner matching and pre-tightening state, excessive preparation time and actual installation and operation time, lining There are no requirements for board assembly clearance, etc., to achieve the effect of ensuring reusability, saving disassembly time, and reducing safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

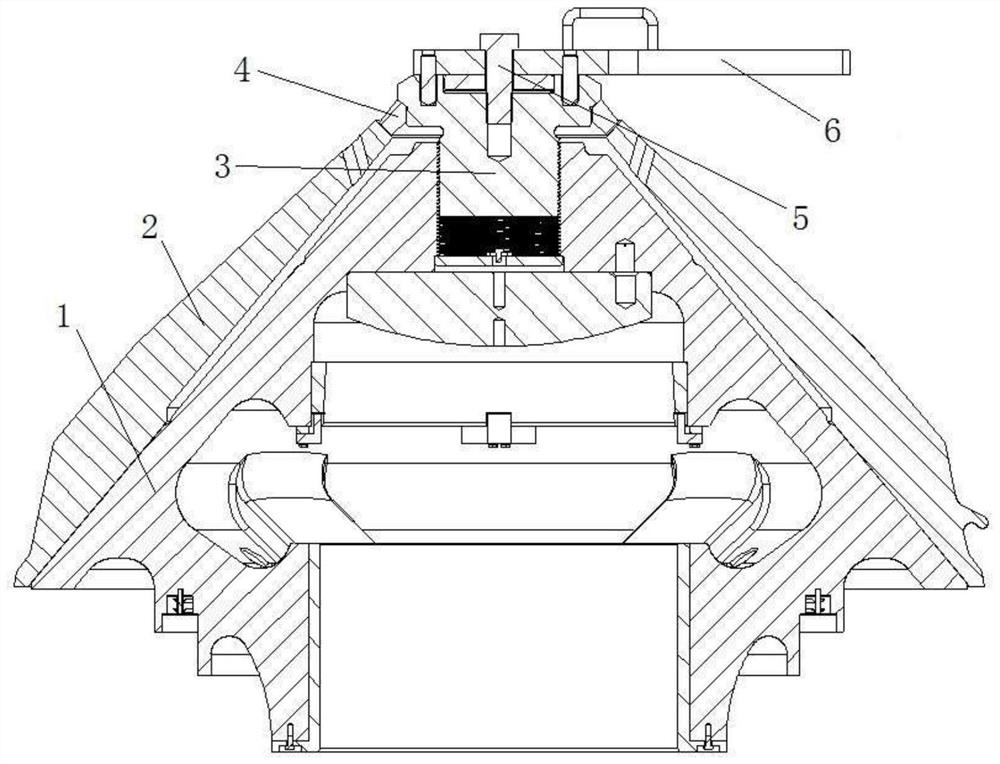

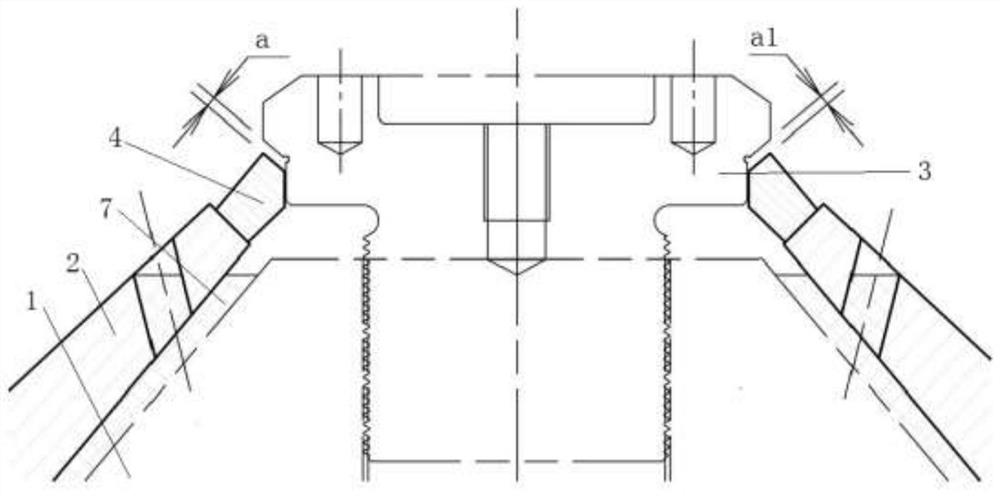

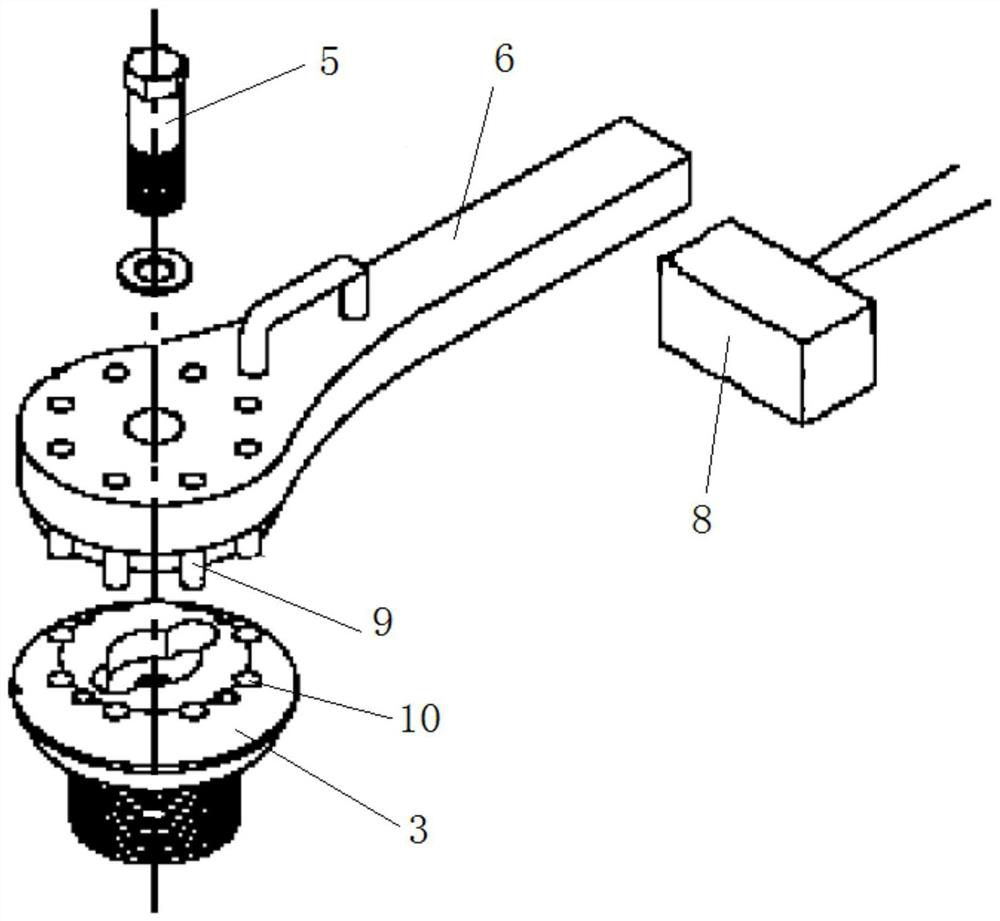

[0071] refer to Figure 1-17 , a multi-cylinder cone crusher liner assembly method, comprising: the installation method of the movable cone liner 2, and the installation method of the fixed cone liner 12. The tools and materials involved in the installation of the moving cone liner include moving cone 1, moving cone liner 2, cutting ring 4, locking bolt 3, locking bolt wrench 6, epoxy resin 7, feeler gauge, tape measure, electric welding machine, 312 Stainless steel welding rod, Loctite LB8150 silver-based anti-seize glue. The tools and materials involved in the installation of the fixed cone liner include fixed cone 11, fixed cone liner 12, adapter ring 13, wedge 16, lag bolt 14, stopper 18, spherical nut 15, nut lock 19, backing plate 17 , Cotter pin 20, epoxy resin 7, feeler gauge, tape measure, electric welding machine, 506 welding rod, Loctite LB8150 silver-based anti-seize glue.

[0072] refer to Figure 1-7 , the installation steps of moving cone liner 2 are as follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com