Magnetic flow liquid variable controllnig valve with two liquid flow resistance channels

A magneto-rheological fluid and control valve technology, applied in fluid pressure actuation devices, fluid pressure actuation system components, servo motors, etc. Problems such as flow resistance channels, etc., to achieve the effect of being suitable for mass production, increasing the shear area, and uniform radial size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

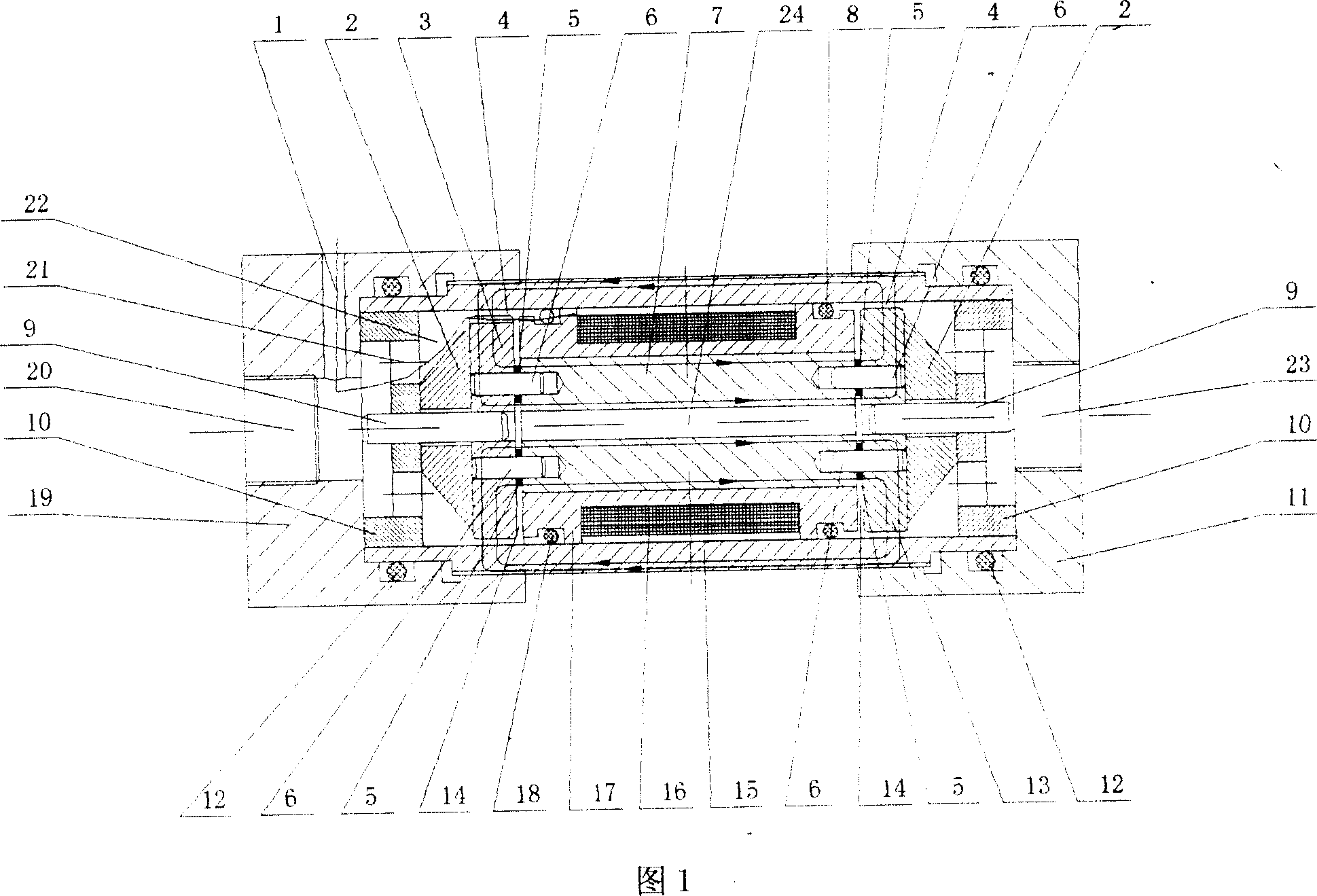

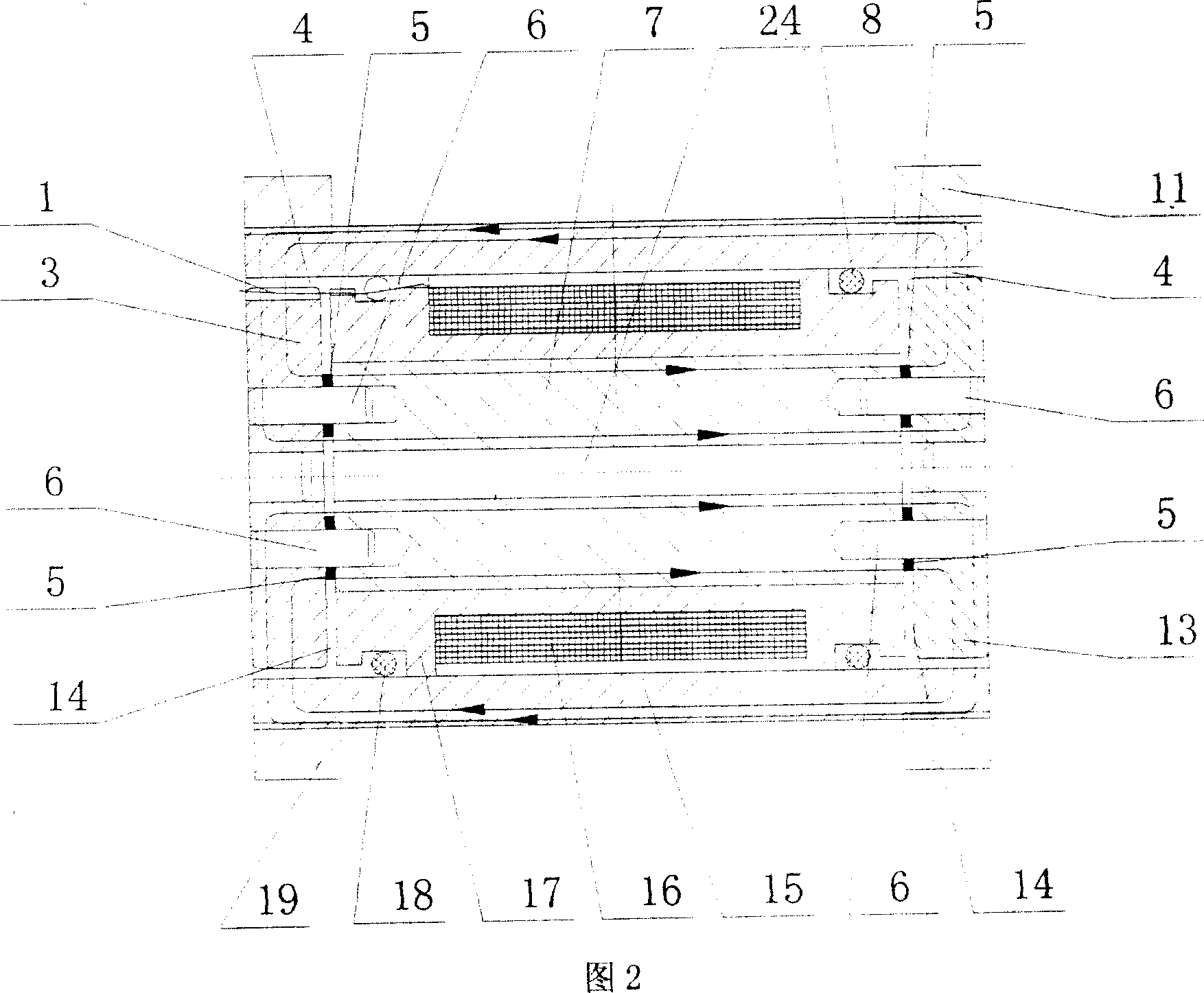

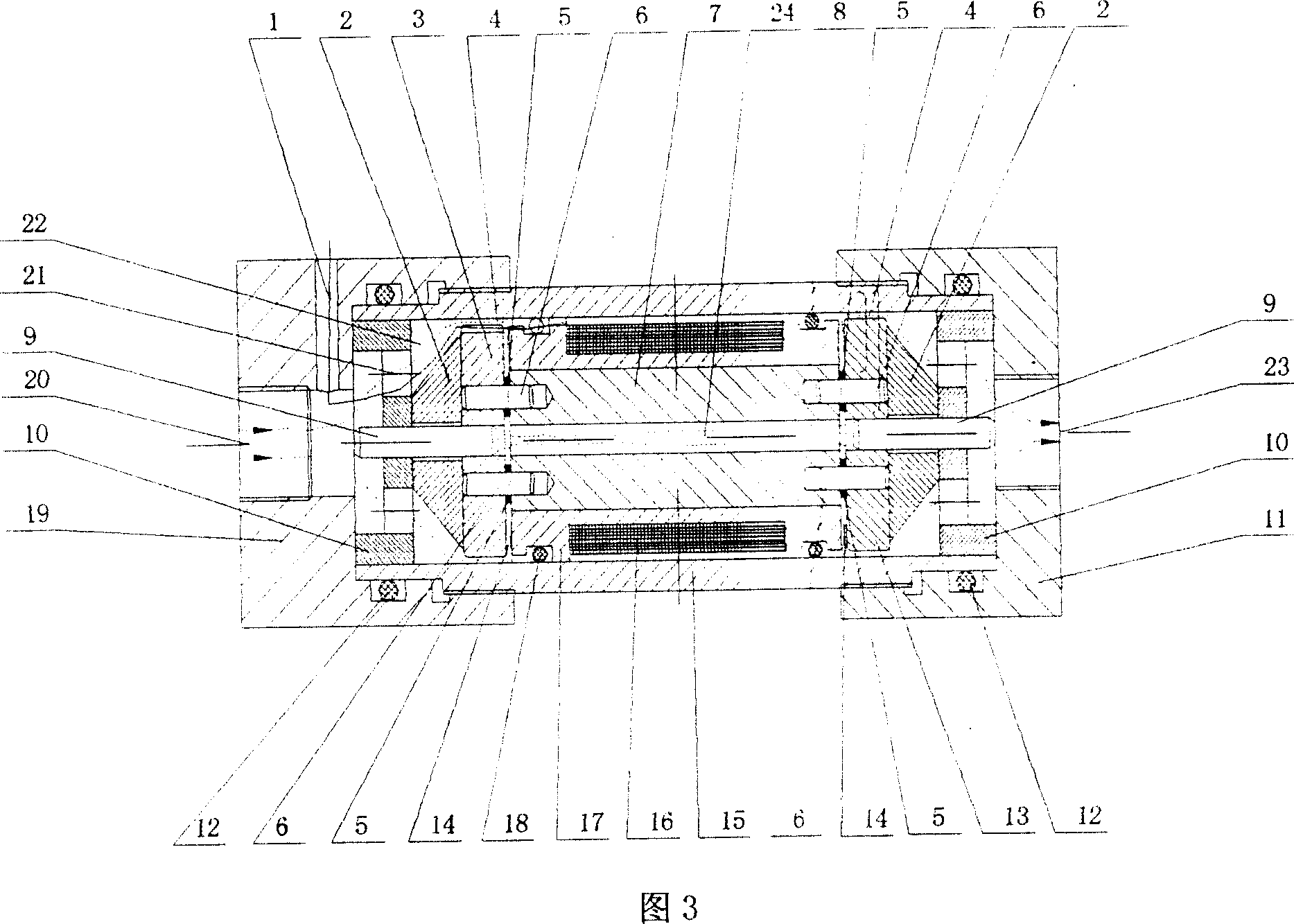

[0029] Below in conjunction with accompanying drawing, structure of the present invention will be further described:

[0030] In the drawings: 1 is the lead wire, 2 is the guide block, 3 is the magnetic disc at the end of the lead wire, 4 is the annular liquid flow resistance channel, 5 is the non-magnetic gasket, 6 is the connecting pin, 7 is the valve core, 8 is a sealing ring, 9 is a positioning pin, 10 is a positioning block, 11 is a valve end cover, 12 is a sealing ring between the end cover and the cylinder, 13 is a magnetic disc, and 14 is a disc-shaped liquid flow resistance channel , 15 is the cylinder, 16 is the excitation coil, 17 is the non-magnetic wire rack, 18 is the sealing ring on the lead wire side of the wire rack, 19 is the valve end cover on the lead wire side, 20 is the liquid inlet hole, 21 is the diversion hole , 22 magnetorheological fluid, 23 is the liquid outlet, 24 is the center hole of the valve core

[0031] With reference to accompanying drawing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com