Technological method for raising toughness and hardening layer depth of heavy truck axle shaft

A technology of hardened layer depth and heavy-duty vehicles, which is applied in the field of heat treatment, can solve the problems of not being able to guarantee the use of half shafts, fracture of shaft diameter fillets, and affecting the quality of the whole vehicle, and achieve the effects of increased deformation, stable performance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

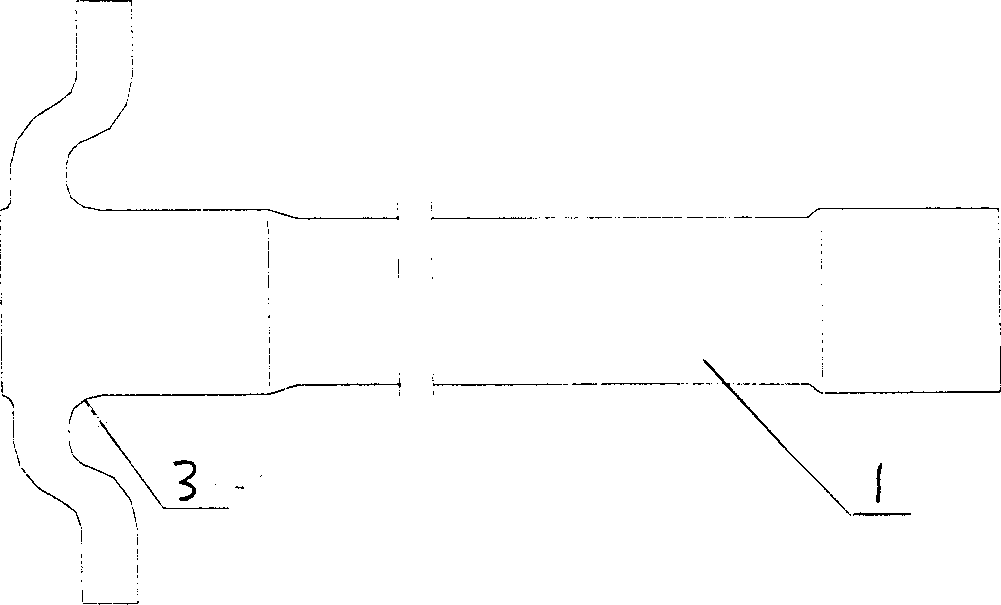

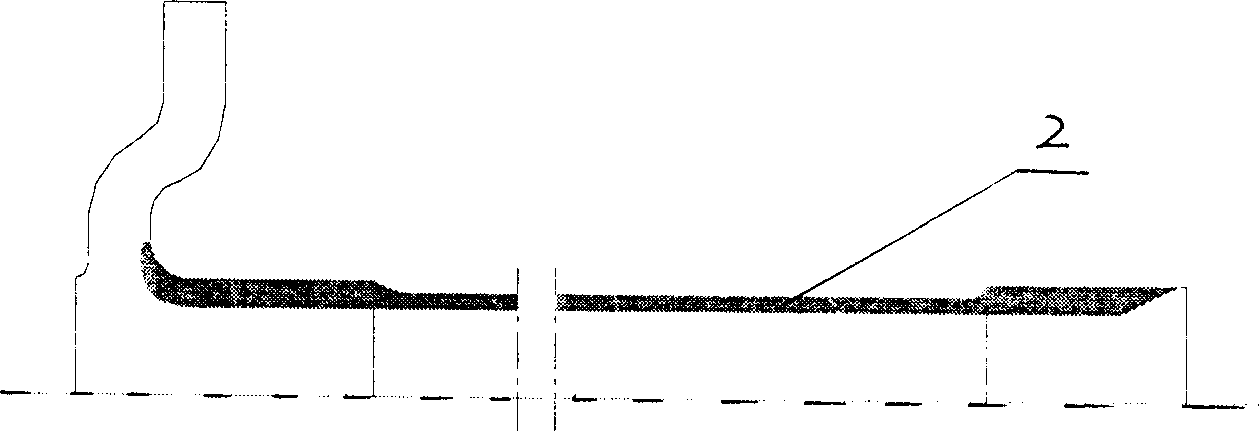

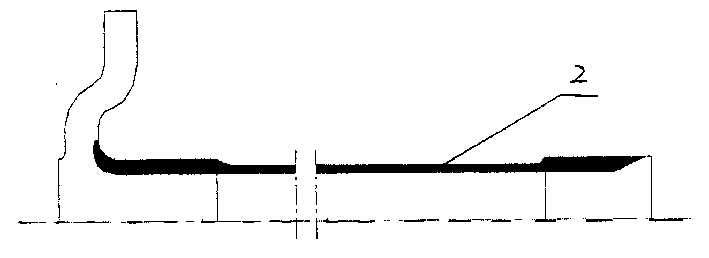

[0016] Embodiment 1: The steps are as follows: firstly, the material is blanked, and the material of the half shaft 1 is 42CrMo; forging is carried out on a flat forging machine; the blank is subjected to quenching and tempering treatment on a heat treatment production line, and its process parameters: quenching temperature is 880 ° C, heating time For 160 minutes, the quenching medium is diesel oil, the tempering temperature is 610°C, the heating time is 180 minutes, and then water cooling; CNC machine tools are used for machining, the diameter of the semi-axis is φ58mm; medium frequency induction quenching, using 2500HZ, 100KW quenching machine tools, its Process parameters: power supply output power is 68KW, frequency is 1700HZ, workpiece moving speed is 2.1mm / s, quenching temperature is 890°C, cooling with 10% Jinyu quenching fluid, and then heating the disk surface statically for 12s, delay spraying water The time is 2s; when the semi-shaft is quenched in the induction coi...

Embodiment 2

[0017] Embodiment 2: The method steps are the same as in Embodiment 1, except that the quenching and tempering process parameters are that the quenching temperature is 850° C., the heating time is 140 minutes, the quenching medium is diesel oil, the tempering temperature is 560° C., and the heating time is 180 minutes. Minutes, then water cooling; medium frequency induction hardening, use 2500HZ, 100KW quenching machine tool, its process parameters: power output power is 66KW, frequency is 1680HZ, workpiece moving speed is 1.9mm / s, quenching temperature is 890°C, using 12% Jinyu The quenching liquid is cooled, and then the plate surface is statically heated for 15s, and the delayed water spraying time is 2s; when the half shaft is quenched in the induction coil, the surface gap between the induction coil and the half shaft rod is 7mm, and the lower plane of the induction coil and the The gap in the vertical direction of the blue plate plane is 5mm. After processing and testing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com