Draught fan and air conditioner with draught fan

A technology for air conditioners and fans, applied in air conditioning systems, machines/engines, household appliances, etc., to achieve the effect of compact overall structure, preventing incomplete vaporization, and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

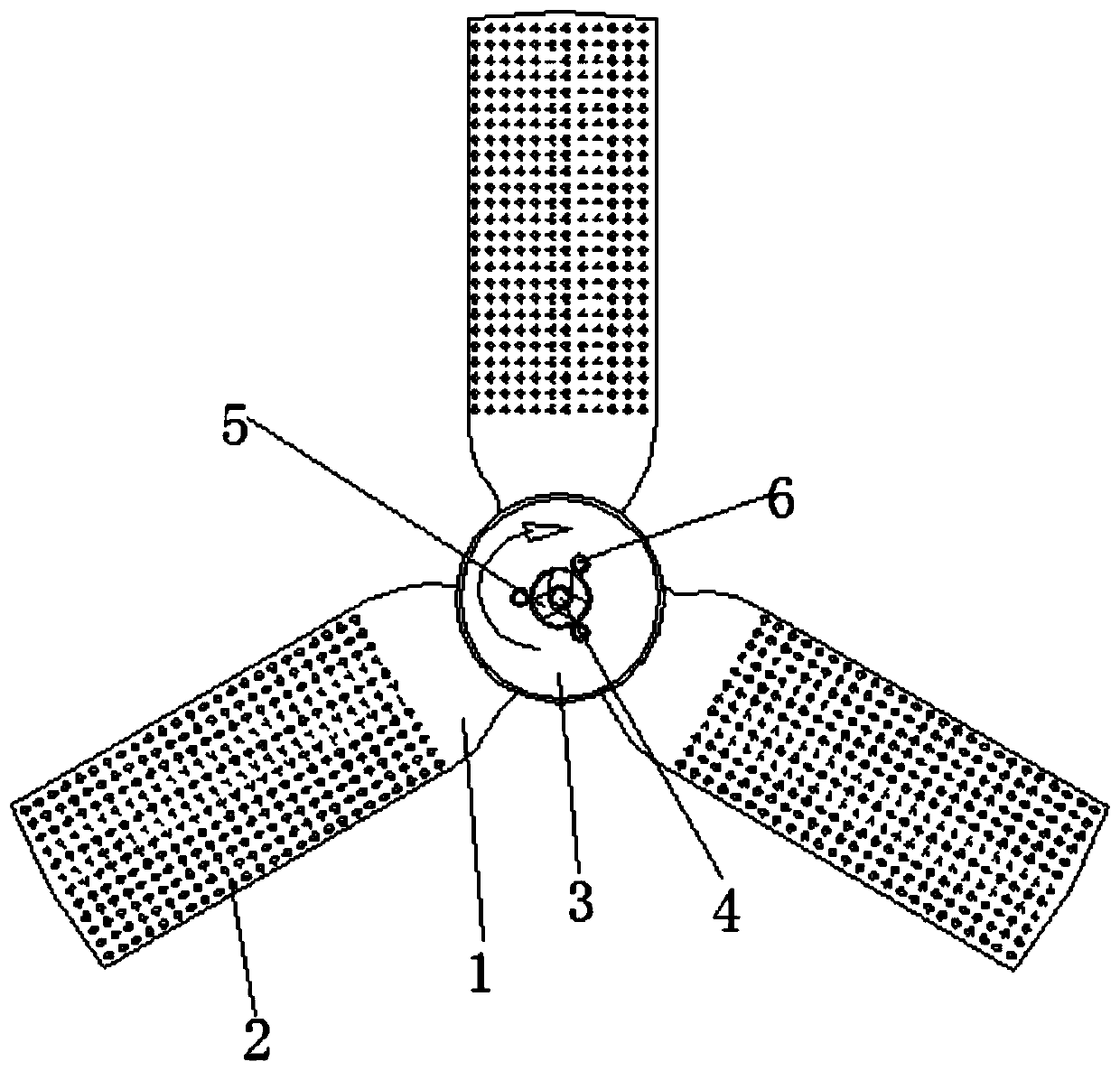

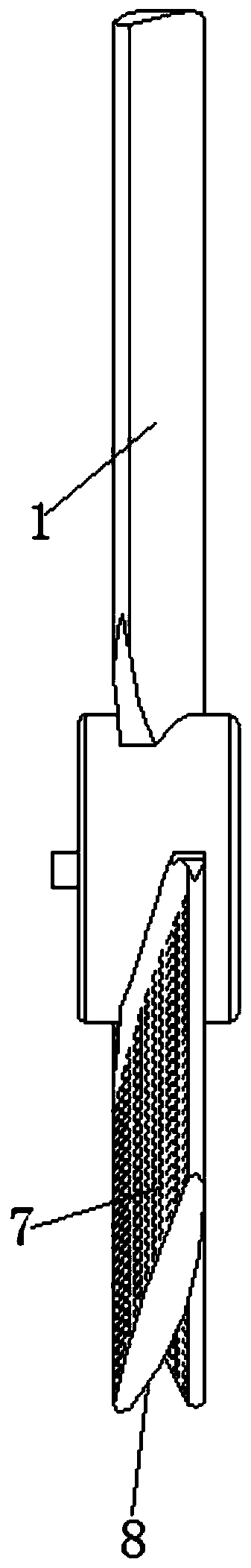

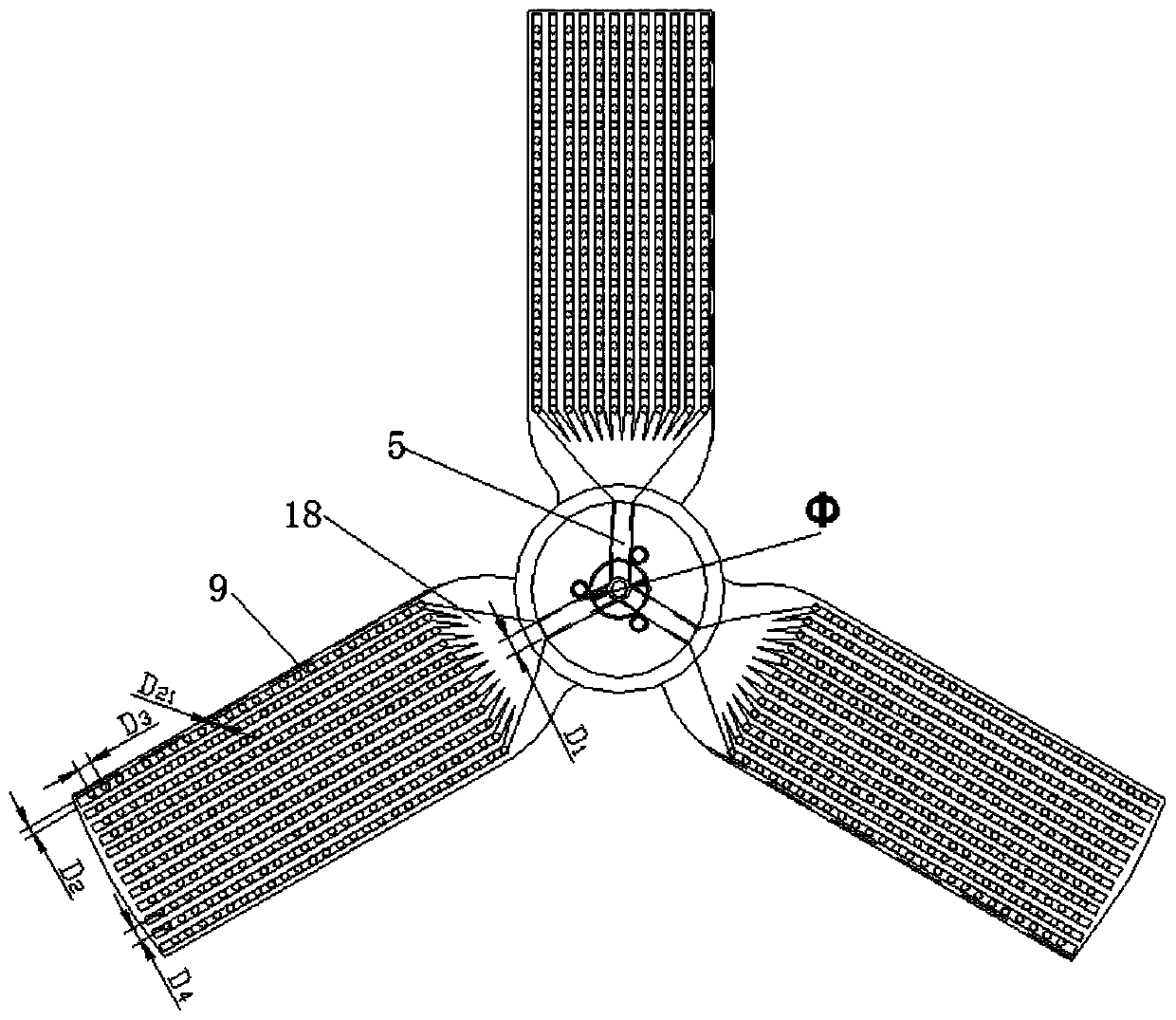

[0049] like figure 1 - image 3 As shown, this embodiment provides a fan, including: a rotating body 3 , blades 1 , microporous channels 9 and air holes 2 .

[0050] Blades 1, at least two, are arranged on the rotating main body 3; the microporous flow channel 9 is arranged inside the blade 1, and during the rotation of the blade 1, the microporous flow channel 9 is connected with the water source; the vent hole 2 is arranged on the blade The suction surface 7 of 1 communicates with the micropore flow channel 9. The suction surface 7 of the blade 1 is the side where the peripheral airflow pressure of the blade 1 is lower than the atmospheric pressure during the rotation process. The vent hole 2 introduces the negative pressure into the micropore flow channel 9 Inside, the vaporization of water in the microporous channel 9 is accelerated, and the vaporized water vapor is sent out by the rotating blade 1 .

[0051] By setting the microporous flow channel 9 connected to the wat...

Embodiment 2

[0068] like Image 6 - Figure 10 As shown, the difference between this embodiment and embodiment 1 is:

[0069] The fan in this embodiment is a centrifugal fan. As an alternative embodiment, it is also possible that the fan is a cross-flow fan.

[0070] The rotating main body 3 of the blower fan in this embodiment includes a top plate 11 and a chassis 12, the blade 1 is connected between the top plate 11 and the bottom plate 12, the top plate 11 is an annular structure, and the top plate 11 is provided with an inner cavity 10, and The cavity 10 is in communication with the microporous flow channel 9 on each blade 1 , and also includes a water supply main pipe 4 in communication with the inner cavity 10 . Specifically, the inner cavity 10 in this embodiment is a hollow water separator.

[0071] Specifically, the main water supply pipe 4 in this embodiment is arranged at the center of the top plate 11, and the main water supply pipe 4 communicates with the inner cavity 10 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com