Waste gas bypass valve of turbocharger

A wastegate valve, turbocharger technology, applied in the direction of machines/engines, internal combustion piston engines, mechanical equipment, etc., can solve problems such as easy vibration, reduced engine performance, dynamic fluctuation of exhaust gas pressure, etc., to achieve control accuracy and Increased accuracy, increased exhaust flow area, and nearly linear flow control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

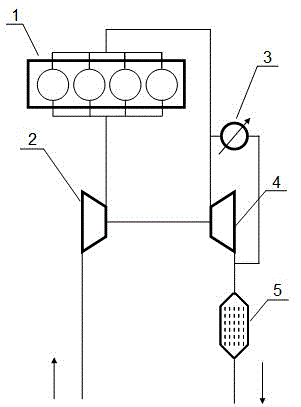

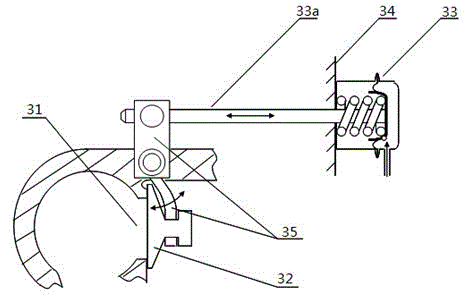

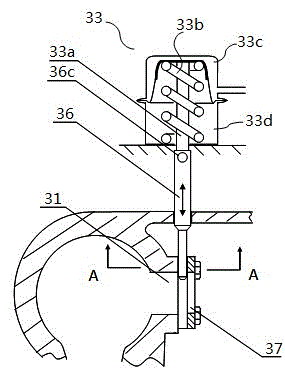

[0027] image 3 The wastegate valve of the turbocharger shown, the wastegate valve has a bypass channel 31 that connects the inlet and outlet of the turbine, and opens the opening of the bypass channel Or the closed spool 36, and the driver 33 that controls the movement of the spool.

[0028] see Figure 5 , the valve core 36 includes a valve stem portion 36a and a valve plate portion 36b connected to the valve stem portion. In this embodiment, the valve plate portion 36b is in the shape of a rectangular plate surface. Of course, the valve plate portion can also be polygonal or circular. It is only necessary to ensure that the valve plate part 36b can completely block the opening after the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com