Flexible packaging bag and support unit

A technology of flexible packaging bags and support units, applied in the field of packaging liquid products, support units of flexible packaging bags

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

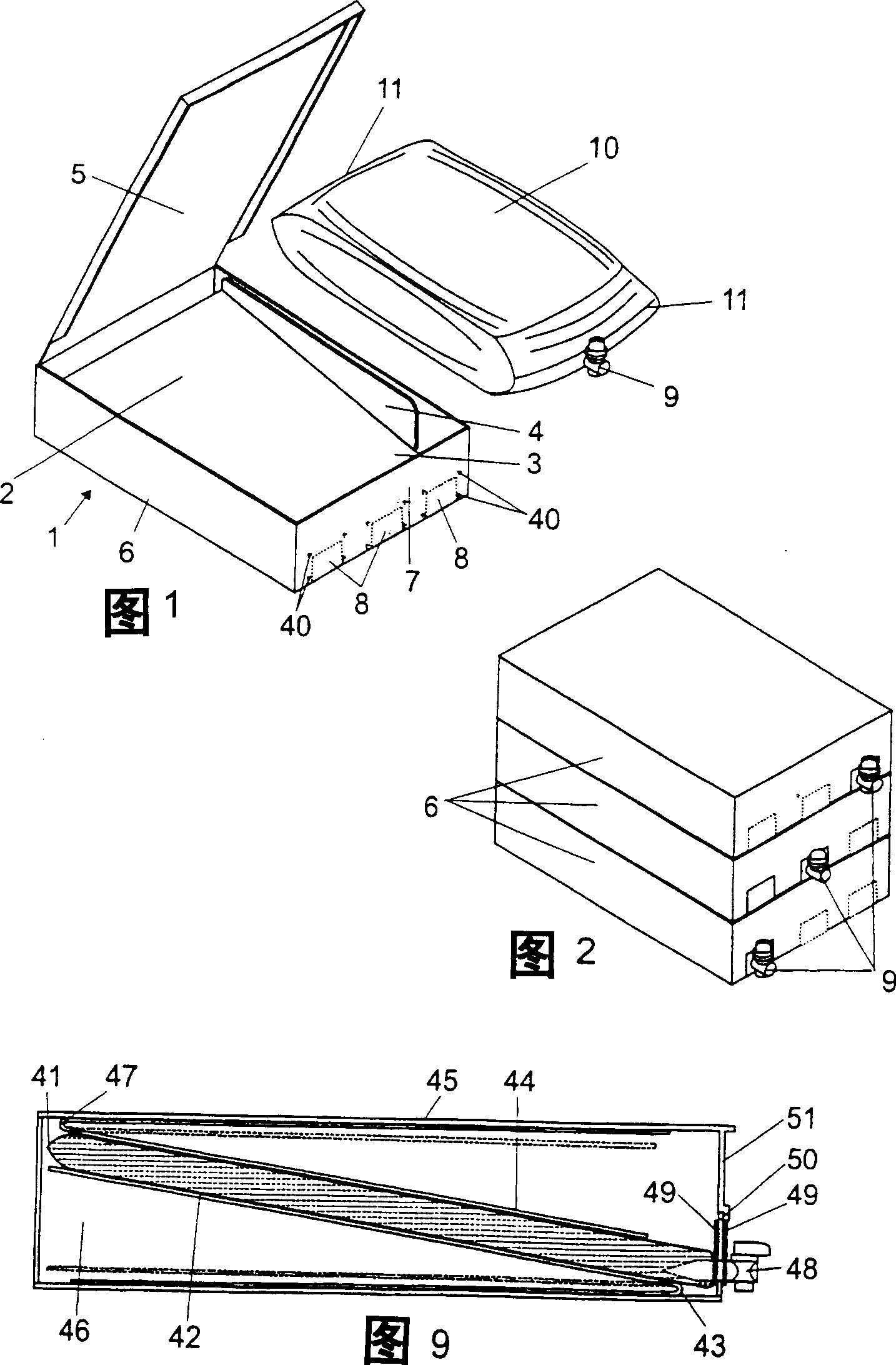

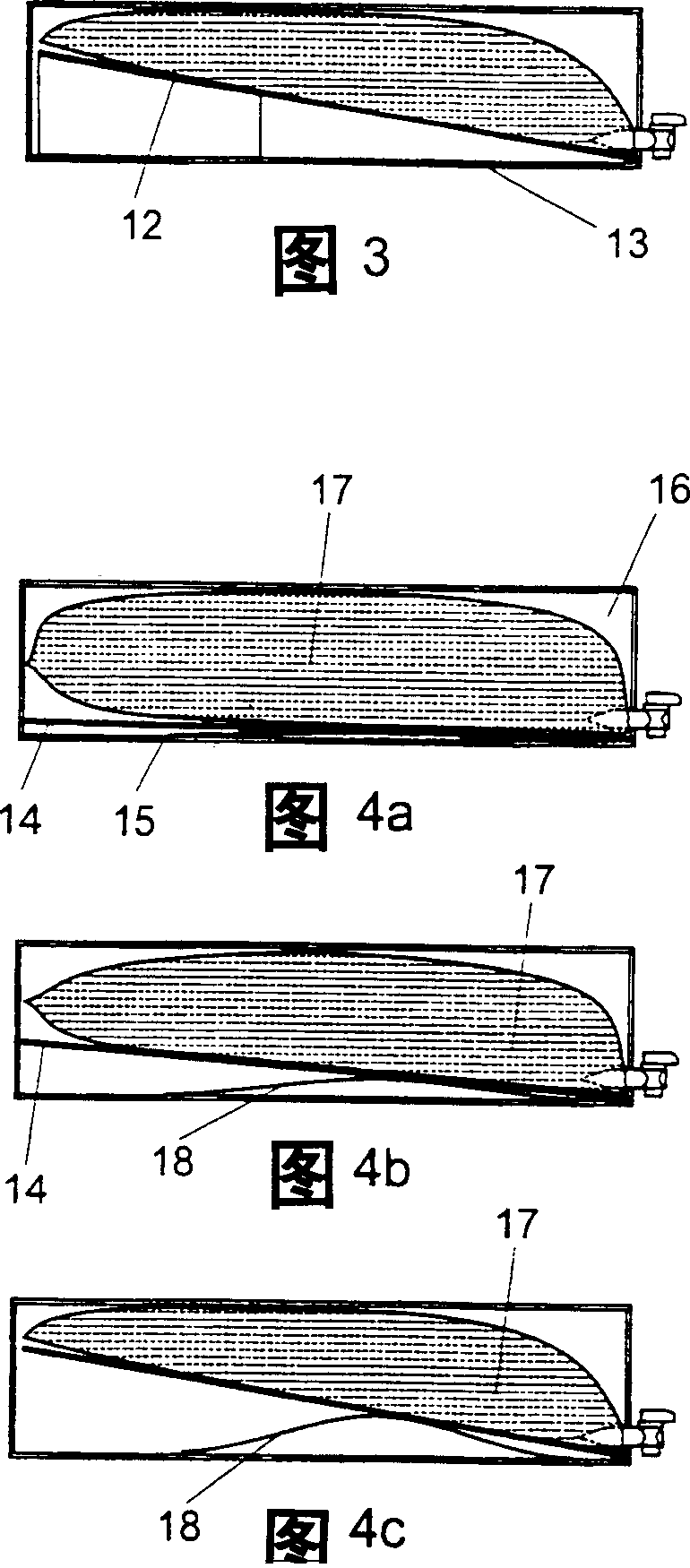

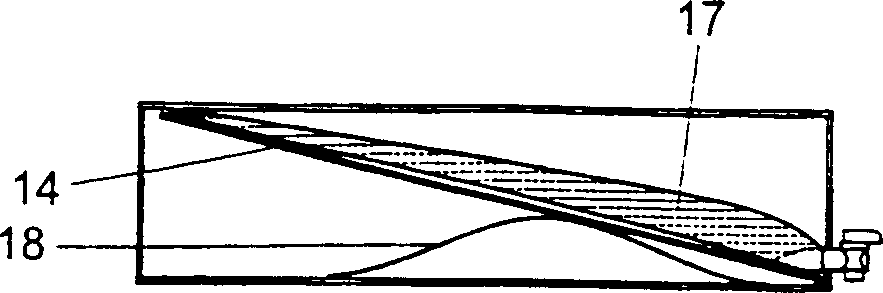

[0030] In the embodiment shown in FIG. 1 of the present invention, a supporting unit, indicated by the symbol 1), includes a supporting plate 2, which is inclined upward and backward from the front edge 3 at least under unstressed conditions. The supporting plate has two opposite side walls 4. In order to adapt to the condition that the supporting plate is inclined relative to the side 5 of the packaging box 6, the height of the side walls 4 is reduced from the front end to the rear end, and the packaging box 6 is cleverly accommodated The support plate. The packaging box 6 has a front side wall 7, and the front side wall 7 has three equidistant and removable areas 8 for accommodating the discharge unit 9, and the discharge unit 9 is connected to the plastic packaging bag 10 by a valve. On the plan view, the size of the plastic bag is such that it can be completely contained in the box when it is full. The plastic bag 10 is preferably in such a style that it is formed between a pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com