Micro loudspeaker

A technology of micro-speaker and shell, applied in the field of electro-acoustics, can solve the problems of uneven coating, inability to fix, affecting the performance of micro-speakers, etc., and achieve the effect of ensuring the normal flow direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

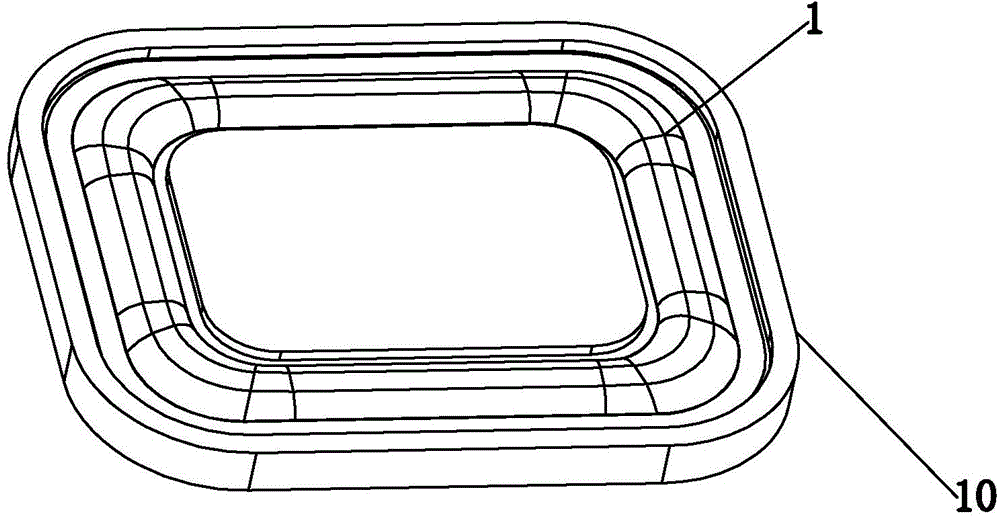

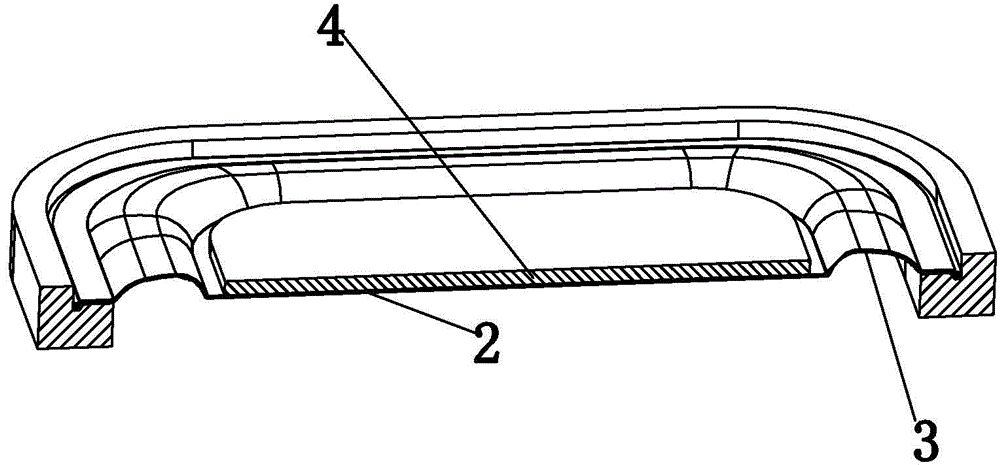

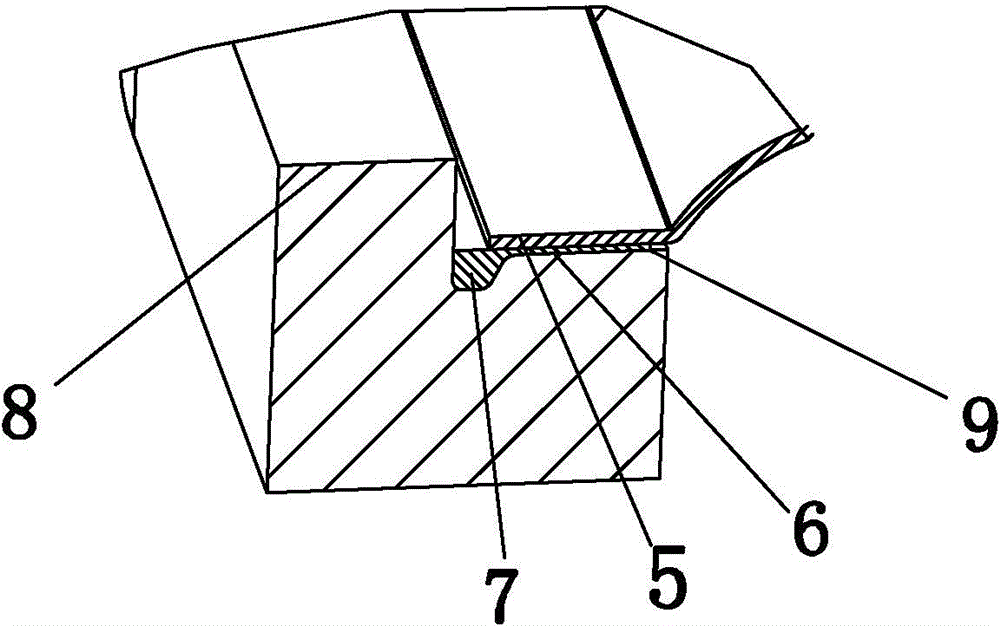

[0016] see Figure 1-Figure 3 As shown, the microspeaker of the present invention includes a diaphragm 1 and a housing 10, and the diaphragm 1 includes a spherical top 2 and a ring portion 3; A joint part 5 is provided; the joint part 5 of the diaphragm 1 and the shell 10 are bonded and fixed through the adhesive layer 6; the diaphragm joint part 5 is combined with the bonding surface of the upper surface of the shell 10; Glue overflow groove 7; the outer edge of the diaphragm joint 5 partially covers the glue overflow groove 7.

[0017] Through the above technical solution, the glue overflow groove 7 is provided on the outer edge of the bonding surface of the micro-speaker diaphragm 1 and the housing 10, which provides a space for the overflow glue generated during the fixing process of the diaphragm 1, and compared with the prior art, it can avoid The uneven application of glue will lift up the periphery of the diaphragm 1, and it can prevent the overflowing glue from flowi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com