Free forging method for conical inner hole ring type forge piece

A forging method and inner hole technology, applied in the field of free forging, can solve the problems of affecting the service life of parts, cutting off forgings, and increasing the weight of forgings, so as to increase the service life, reduce the weight of forgings, and ensure the smoothness of internal streamlines. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] The free forging method of the tapered inner hole ring class forging of the present invention is specifically implemented according to the following steps:

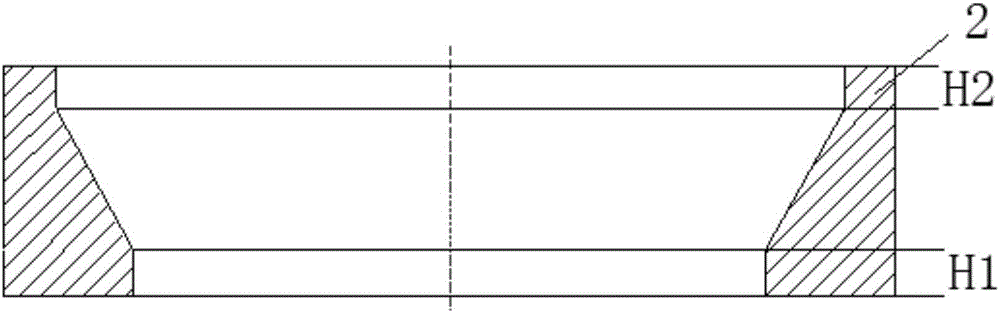

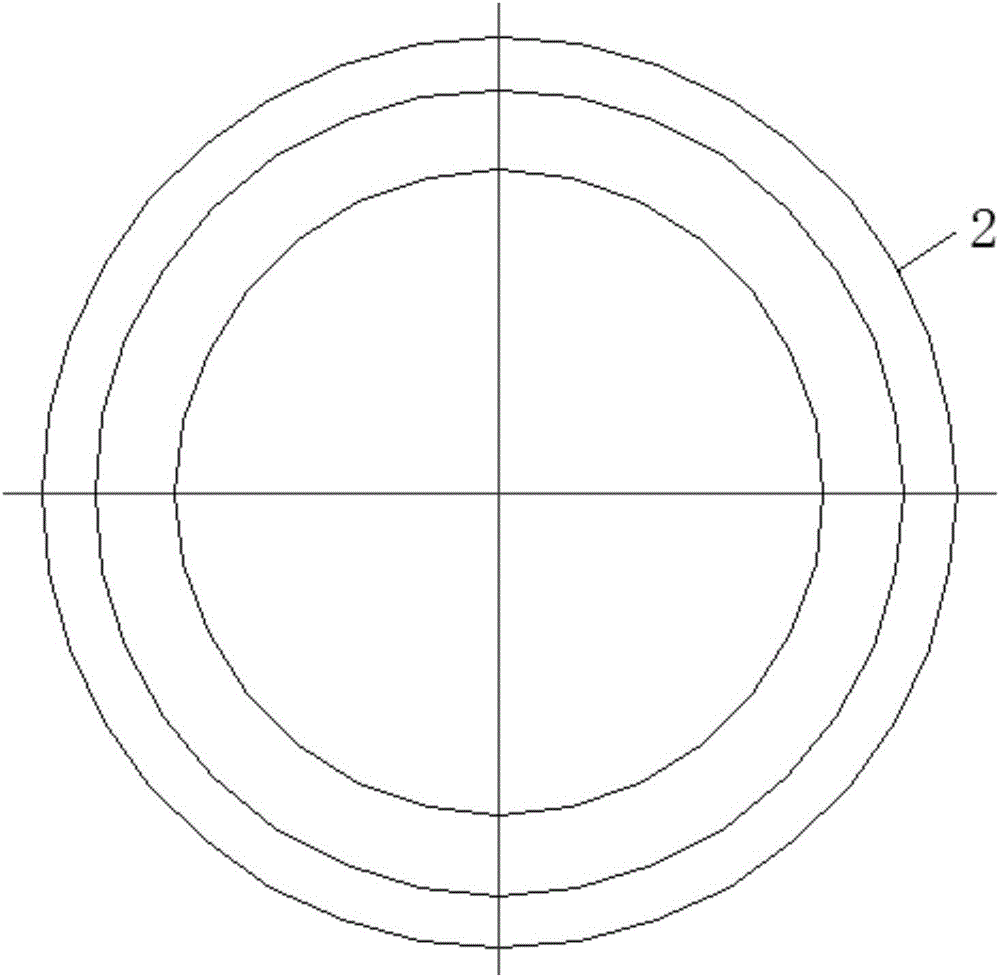

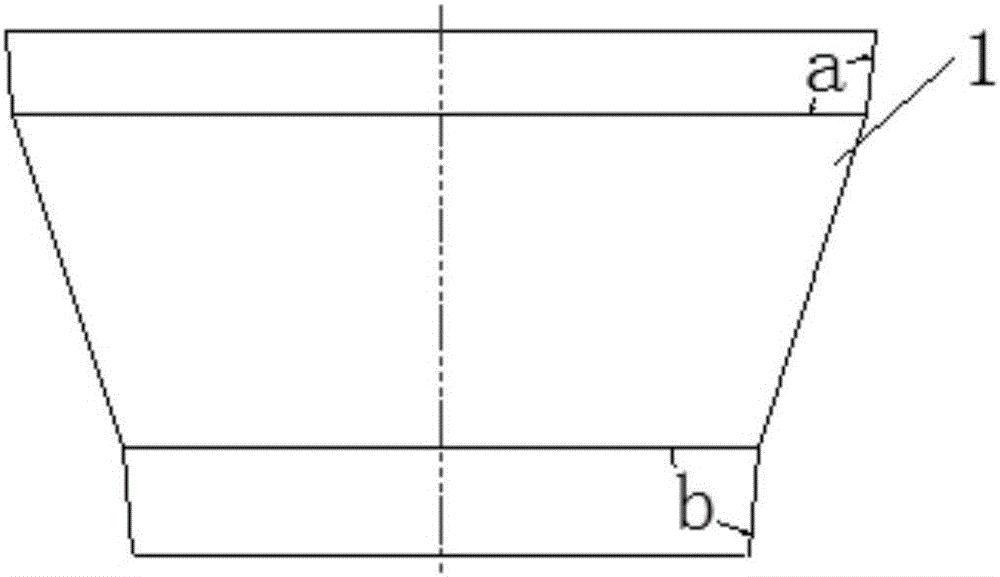

[0041] Preparatory steps, formulate forging process according to different specifications of forgings with conical inner hole rings, according to the forging diagram ( figure 1 and figure 2 ) size to make bulging punch 1, conical horse bar 3 and cylindrical horse bar 4 of corresponding size; the maximum diameter of bulging punch 1 is 1 / 2 of the small end diameter of the tapered inner hole of forging 2, and the 1 The taper at the upper and lower ends is 5° for easy ejection (equivalent to 95° at a and 85° at b), the taper and height of the cone in the middle section should be consistent with the taper and height of the inner hole of the forging 2; The taper of the cone of the horse bar 3 should be 3-5° smaller than the taper of the inner hole of the forging 2, and the length of the second cylinder of the tapered h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com