A kind of free forging method of cone base forging

A technology for conical cylinders and forgings, which is applied in the field of free forging of conical cylinder table forgings, can solve the problems affecting the service life of conical truncated cylinder forgings, increase the weight of conical truncated cylinder forgings, and increase the amount of processing man-hours. Market competitiveness, reduction of processing man-hours, and the effect of simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0045] A kind of free forging method of conical tube base forging, specifically carries out according to the following method:

[0046] Step 1, forging a blank with a through hole, specifically according to the following steps:

[0047] Step 1.1, putting the steel ingot into a calcination furnace, and calcining at a temperature of 1200°C-1220°C for 12-14h;

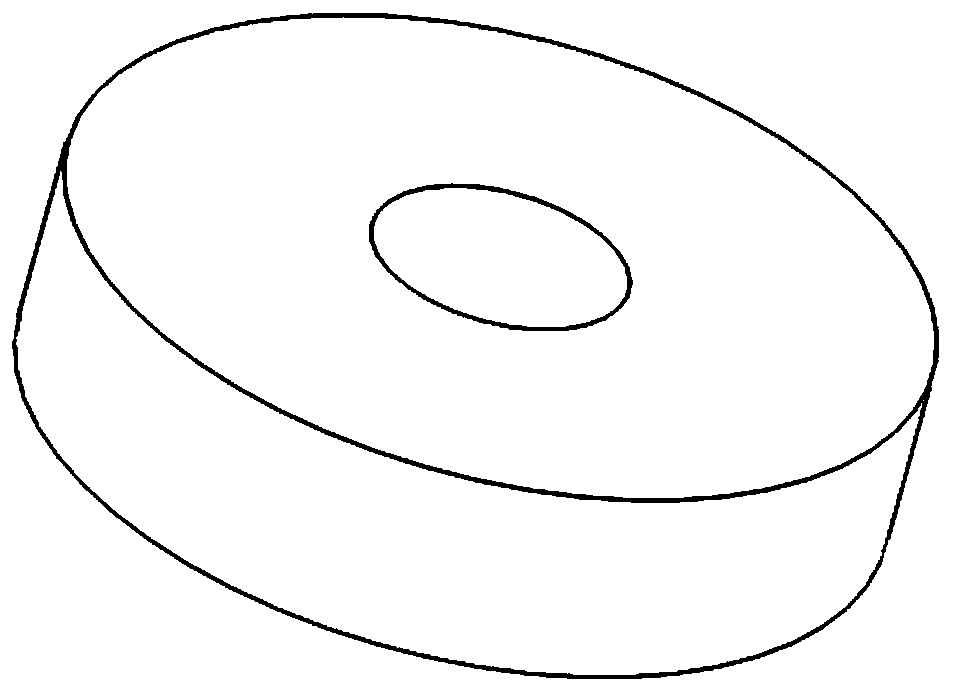

[0048] Step 1.2, after chamfering the steel ingot after calcination, cut off the nozzle and riser, and then round and level off; punch holes on the round and level steel ingot to obtain the following: figure 1 Blank shown with through holes.

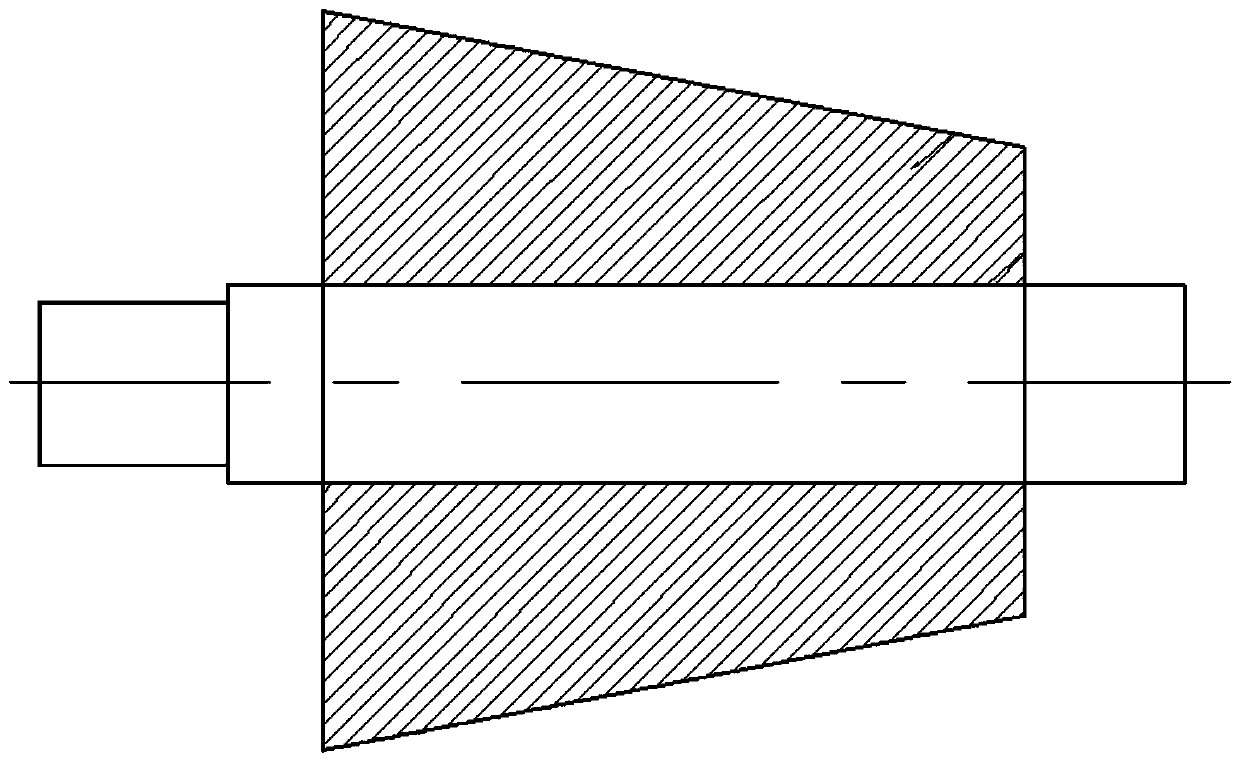

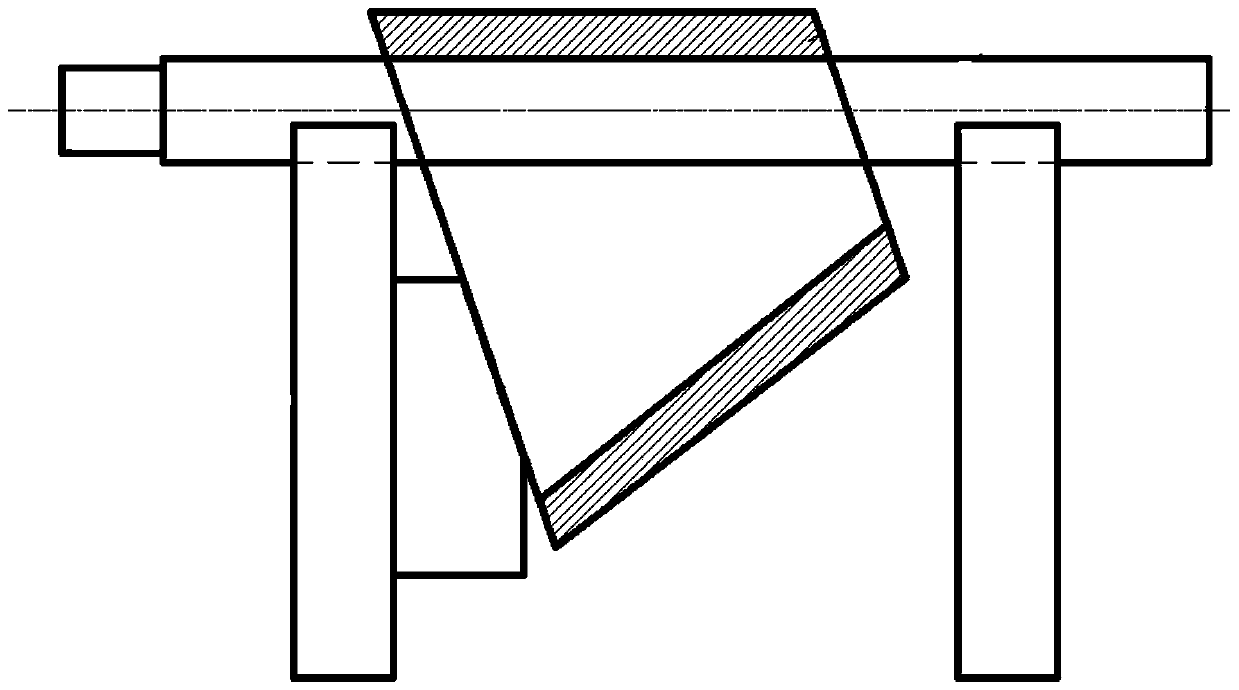

[0049] In step 2, the outer wall of the blank is pulled out into a conical surface while the blank is drawn out, and the following is obtained: figure 2 Shown conical surface blank, specifically carry out according to the following steps:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com