Forming method and forming device for doubling plate structural members

A molding device and molding method technology, applied in the field of parts processing, can solve the problems that the superplastic forming/diffusion bonding process cannot be realized, the temperature difference between superplastic forming and diffusion bonding is large, and the cost is high, so as to achieve shortened processing cycle, low cost, The effect of reducing the cost of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

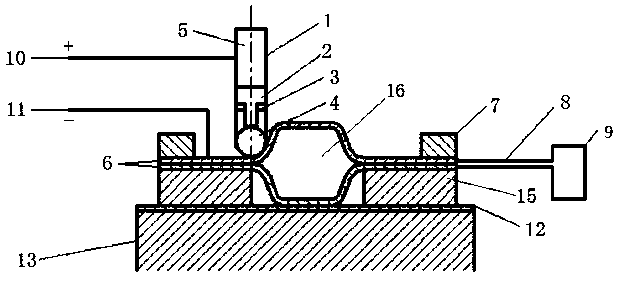

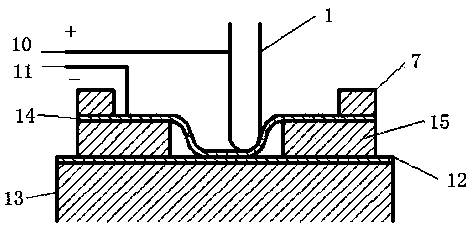

[0037] Such as Figures 1 to 2 Shown, a kind of forming method of double-layer plate structure, comprises the following steps:

[0038] X1, the material board is cut into multiple pieces by the shearing machine, two pads 15 are placed on the processing platform 13, there is a distance between the two pads 15, the cut material board is placed on the pads 15, and The edge end of the material plate is fixed on the spacer 15 by the fixing fixture 7, and the middle part of the material plate covers the distance between the two spacers 15;

[0039] X2, the material plate is connected to the negative pole of the power supply through the negative electrode lead 11, the processing tool head 1 is connected to the positive pole of the power supply through the positive electrode lead 10, the processing tool head 1 is in contact with the material plate, and the processing tool head 1, the material plate and the power supply form a closed circuit;

[0040] X3. The current in the circuit ge...

Embodiment 2

[0050] Such as Figures 1 to 2 Shown, a kind of forming method of double-layer plate structure, comprises the following steps:

[0051] X1, the material board is cut into multiple pieces by the shearing machine, two pads 15 are placed on the processing platform 13, there is a distance between the two pads 15, the cut material board is placed on the pads 15, and The edge end of the material plate is fixed on the spacer 15 by the fixing fixture 7, and the middle part of the material plate covers the distance between the two spacers 15;

[0052] X2, the material plate is connected to the negative pole of the power supply through the negative electrode lead 11, the processing tool head 1 is connected to the positive pole of the power supply through the positive electrode lead 10, the processing tool head 1 is in contact with the material plate, and the processing tool head 1, the material plate and the power supply form a closed circuit;

[0053] X3. The current in the circuit ge...

Embodiment 3

[0065] Such as Figures 1 to 2 Shown, a kind of forming method of double-layer plate structure, comprises the following steps:

[0066] X1, the material board is cut into multiple pieces by the shearing machine, two pads 15 are placed on the processing platform 13, there is a distance between the two pads 15, the cut material board is placed on the pads 15, and The edge end of the material plate is fixed on the spacer 15 by the fixing fixture 7, and the middle part of the material plate covers the distance between the two spacers 15;

[0067] X2, the material plate is connected to the negative pole of the power supply through the negative electrode lead 11, the processing tool head 1 is connected to the positive pole of the power supply through the positive electrode lead 10, the processing tool head 1 is in contact with the material plate, and the processing tool head 1, the material plate and the power supply form a closed circuit;

[0068] X3. The current in the circuit ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com