A four-layer thin-wall mesh part with solid structure and its superplastic forming/diffusion bonding method

A technology of diffusion connection and solid structure, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of low structural rigidity, poor integrity of combined parts, weak strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Implementation examples such as Figure 1-7 As shown, for the superplastic forming / diffusion connection of a four-layer thin-walled mesh part with a solid structure made of TA15 titanium alloy, the specific steps are as follows:

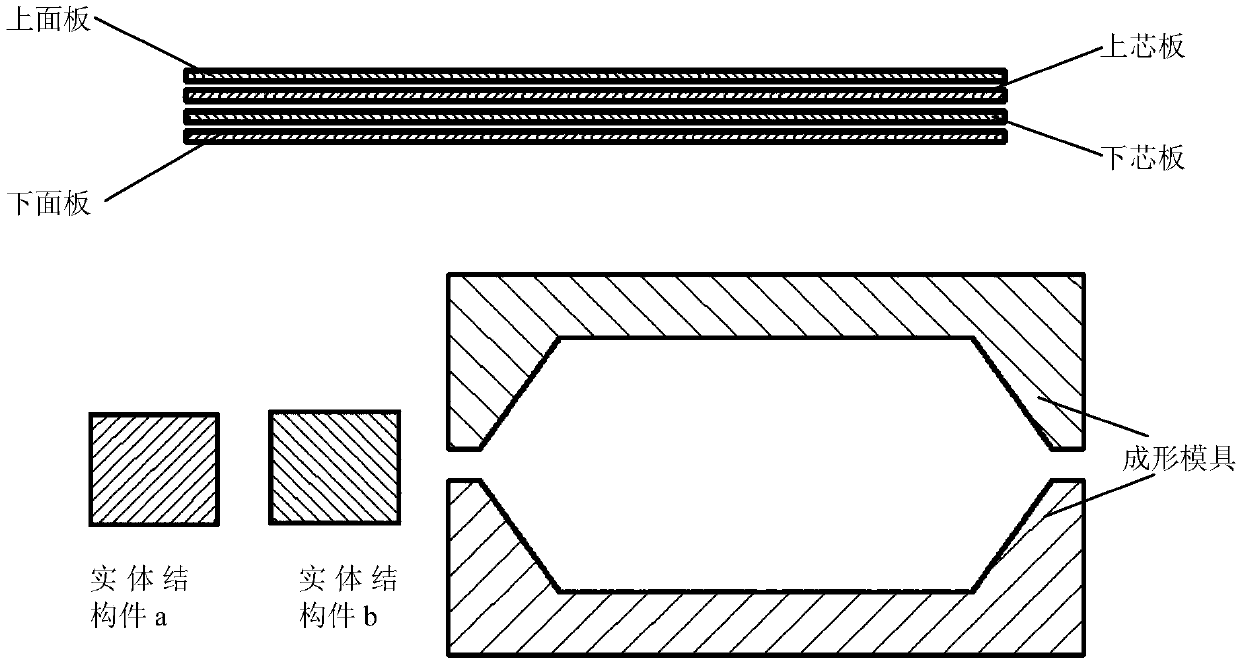

[0028] (1) Preparation of raw materials and forming female mold: such as figure 1 As shown, the raw materials include an upper panel and a lower panel with a thickness of 1 mm, an upper core plate and a lower core plate with a thickness of 1 mm, and a solid structural part a and a solid structural part b. The cavity of the forming female mold is the grid part to be formed Shape; raw material is TA15 titanium alloy;

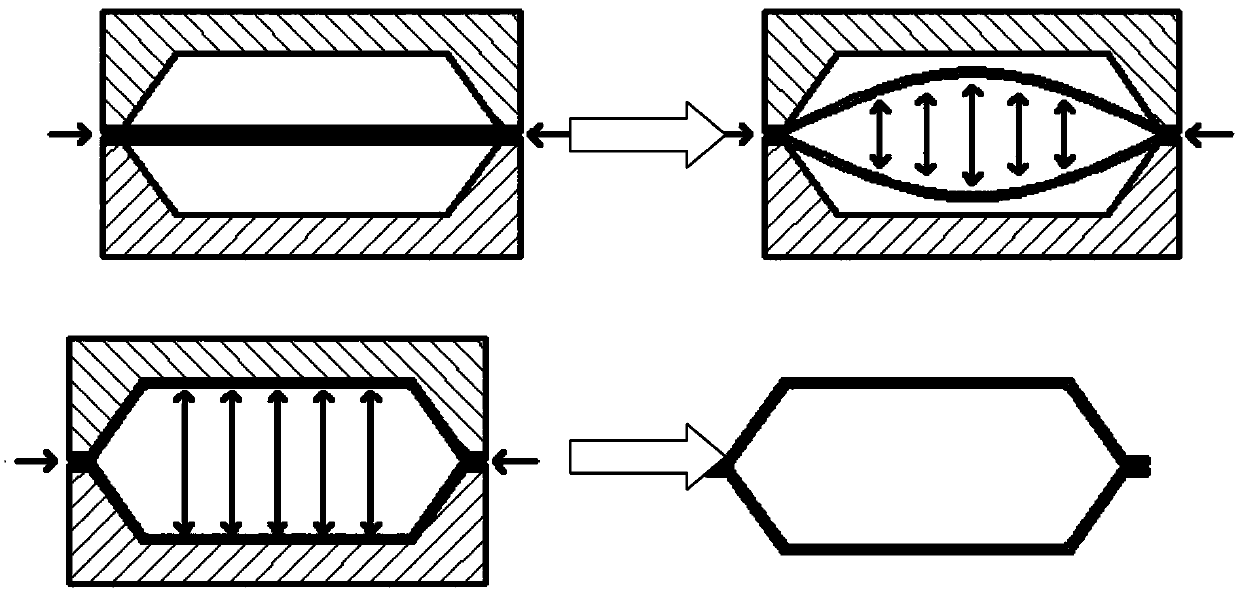

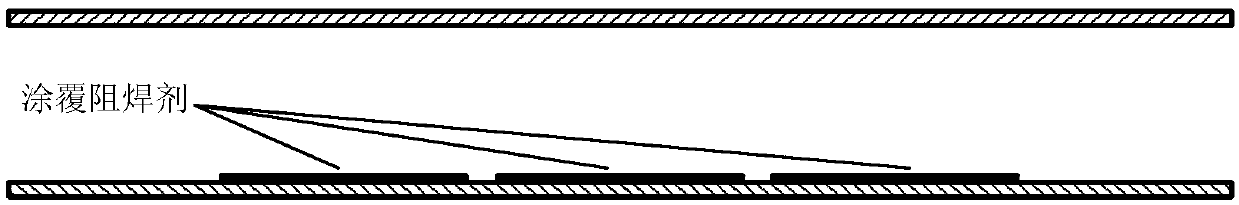

[0029] (2) Forming of two-layer panels: such as figure 2 As shown, the two-layer panels are placed in the forming female mold, and the two-layer panels are placed up and down; then the two-layer panels and the forming female mold are heated to the superplastic forming temperature (about 900°C) of the raw material TA15 titanium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com