Connecting method of dissimilar gamma '-phase reinforced high-temperature alloy

A high-temperature alloy and connection method technology, which is applied in welding equipment, metal processing equipment, welding/welding/cutting items, etc., can solve the problems of large changes in microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

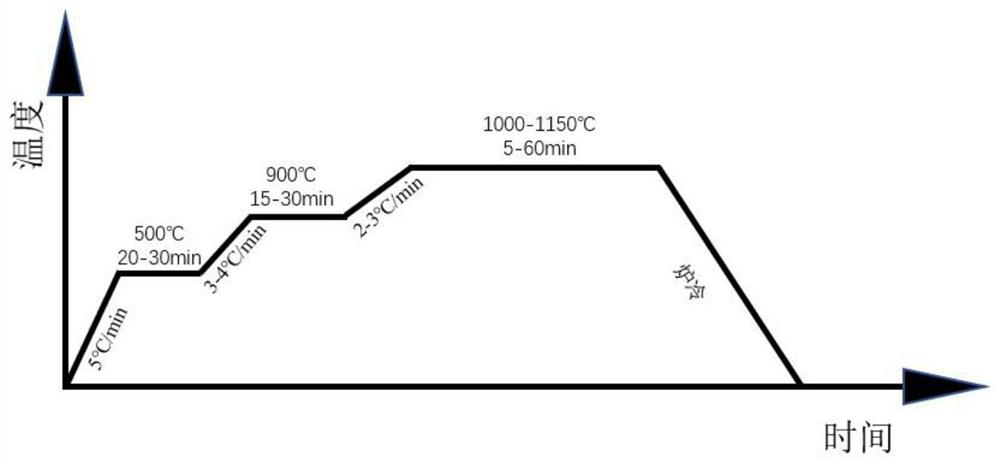

Method used

Image

Examples

Embodiment 1

[0038] Step 1, preprocessing:

[0039] Use a wire cutting machine to cut the Ni 3 Al-based superalloys were cut into 25×10×3mm specimens, and 718Plus alloys were cut into 15×10×3mm specimens.

[0040] Step 2, stress relief annealing:

[0041] The two box furnaces were heated to 850°C and 850°C respectively. After the temperature was stable, the Ni obtained in the first step was 3 The samples of Al-based superalloy and 718Plus alloy were put into preheated corundum crucibles, and the corundum crucibles containing the samples were placed in the constant temperature zones of the two box furnaces, respectively, and kept for 2 hours and 7 hours respectively. After oven cool to room temperature.

[0042] Step 3, solution treatment:

[0043] The box furnace was heated to 1160°C, and after the temperature was stable, the Ni 3 The corundum crucible of the Al-based superalloy sample is placed in the constant temperature zone of the box furnace, and the sample is kept in the box fur...

Embodiment 2

[0054] The difference between this example and Example 1 is that the two base metal alloys are not subjected to the stress relief annealing process. 3 The Al-based superalloy is heated to 1100°C for 7 hours in the box furnace, and the 718Plus alloy is placed in the box furnace, heated to 960°C, and the solution treatment is performed for 3 hours; in step 7, the temperature is raised to 1040° C., holding for 30 minutes to complete the diffusion connection to form a joint, and after the holding is completed, it is cooled to room temperature with the furnace and taken out.

[0055] Others are the same as in Example 1.

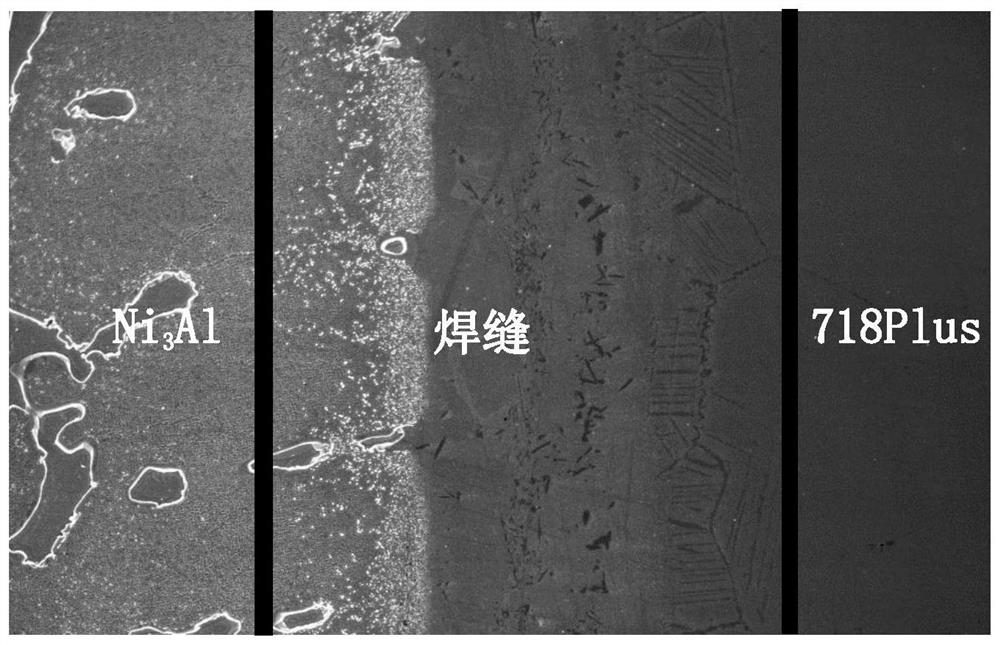

[0056] Get ATI 718Plus alloy with Ni 3 Al-based superalloy TLP connector. The highest tensile strength is 410MPa, and the microhardness value is 578HV. The obtained TLP diffusion joint has very low tensile strength and poor mechanical properties. The elements in the joint area have obvious enrichment in a certain area, and have obvious defects such as pores and...

Embodiment 3

[0058] The difference between this example and Example 1 is that in step 3, the Ni 3 The Al-based superalloy is heated to a temperature of 1180 °C in a box furnace for 5 hours of solution treatment, and the 718Plus alloy is placed in a box furnace, heated to 900 °C, and subjected to a solution treatment for 4 hours; the temperature rises in step 7 At 1040° C., the temperature was maintained for 45 minutes to complete the diffusion connection to form a joint, and after the temperature preservation was completed, it was cooled to room temperature with the furnace and taken out.

[0059] Others are the same as in Example 1.

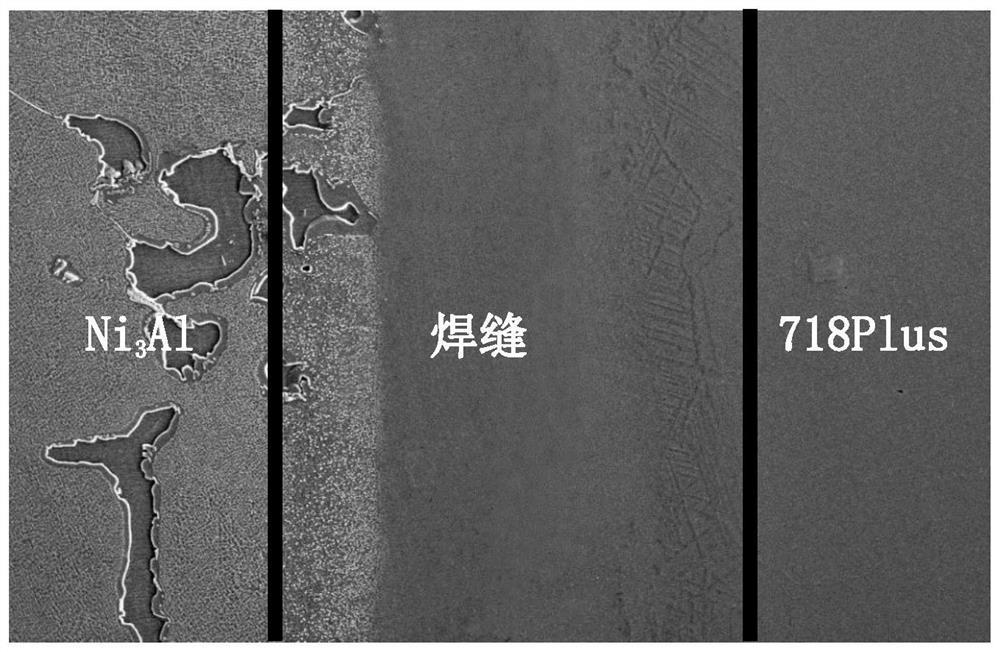

[0060] Get ATI 718Plus alloy with Ni 3 Al-based superalloy TLP connection joint, the microstructure of the welded joint is as follows image 3 shown. The highest tensile strength is 541MPa, and the microhardness value is 512HV. Compared with Example 2, the joint structure and mechanical properties of the obtained TLP diffusion connection joint have been g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com