A kind of preparation device and process of ultra-high strength composite material structure

A composite material and ultra-high-strength technology, which is applied in the field of preparation devices for ultra-high-strength composite structural parts, can solve the problems of affecting the quality of connectors, poor quality of connectors, and easy formation of brittle intermetallic compounds, etc., to achieve improved diffusion bonding The process and forming are stable and accurate, and the effect of good insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

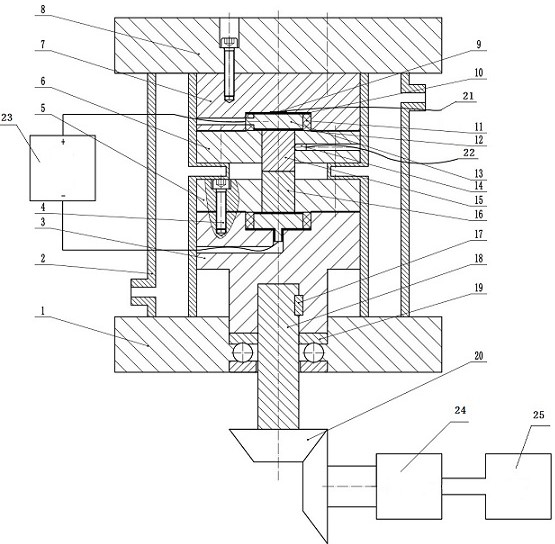

[0028] A preparation device for ultra-high-strength composite structural parts, such as figure 1 As shown, it includes an upper seat 8, an upper backing plate 7, an upper die 6, a copper electrode 13, a high-strength ceramic sleeve 11, a strain gauge 9, a thermocouple 14, an insulating paper 10, a graphite paper 12, a lower backing plate 3, a lower die 5. Base 1, cooling water jacket 2, thrust ball bearing 19, shaft 18, bevel gear 20, reducer 24, motor 25, pulse power supply 23, pressure sensor 21 and temperature sensor 22.

[0029] like figure 1 As shown in the figure, the middle of the base 1 is provided with a through hole, the lower part of the through hole is provided with a thrust ball bearing 19, and the upper part is provided with a lower backing plate 3. In the through hole of the base 1; the middle of the vertical end of the lower backing plate 3 is provided with a shaft hole, and the center of the horizontal end is provided with a copper electrode hole, and one end...

Embodiment 1

[0036] Step 1: The test materials are Mo alloy and Ti6Al4V alloy, and the size of the blank is φ20×50mm; the connecting surface is polished with 150#, 400#, 800#, 1500#, 2000# sandpaper in turn, and then with Al 2 O 3 Powder polished to obtain a near-mirror plane.

[0037] Step 2: Install the upper seat 8, the upper backing plate 7 and the upper die 6 on the upper die surface of the movable beam of the press, and at the same time install the lower die, the lower backing plate and the lower seat on the working table of the press;

[0038] Step 3: Fill the parts of the material Mo alloy and Ti6Al4V alloy in contact with the upper mold and the lower mold with insulating dye, and place the material in the upper mold and the lower mold respectively; cover the cooling water jacket, and then connect the water pipe to the cooling water jacket respectively. The inlet and outlet pipes are connected;

[0039] Use a thermocouple to measure the temperature. After the temperature is stab...

Embodiment 2

[0045] Step 1: The test materials are 60Si2Mn steel and WCu10 tungsten-copper alloy, and the blank size is φ15×50mm; the connecting surface is polished and polished with 150#, 400#, 800#, 1500#, 2000# sandpaper in turn, and then Pickling was carried out, and finally it was placed in an alcohol solution for ultrasonic cleaning, and dried to obtain a near-mirror plane.

[0046] Step 2: Install the upper seat 8, the upper backing plate 7 and the upper die 6 on the upper die surface of the movable beam of the press, and at the same time install the lower die, the lower backing plate and the lower seat on the working table of the press;

[0047] Step 3: Fill the parts of material 60Si2Mn steel and WCu10 tungsten copper alloy in contact with the upper and lower molds with insulating dye, and place the materials in the upper and lower molds respectively; put on a cooling water jacket, and then connect the water pipes to the cooling The inlet pipe of the water jacket is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com