Ceramsite proppant for well producing coalbed methane from coal gangue and preparation method thereof

A technology for coalbed methane wells and coal gangue, which is applied in the field of ceramsite proppant and its preparation, can solve the problems of high production cost of ceramsite proppant, increase the cost of oil and gas exploitation and fracturing construction, etc., and achieves significant economic and environmental benefits, Achieve the effect of resource utilization, reduction of accumulation and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

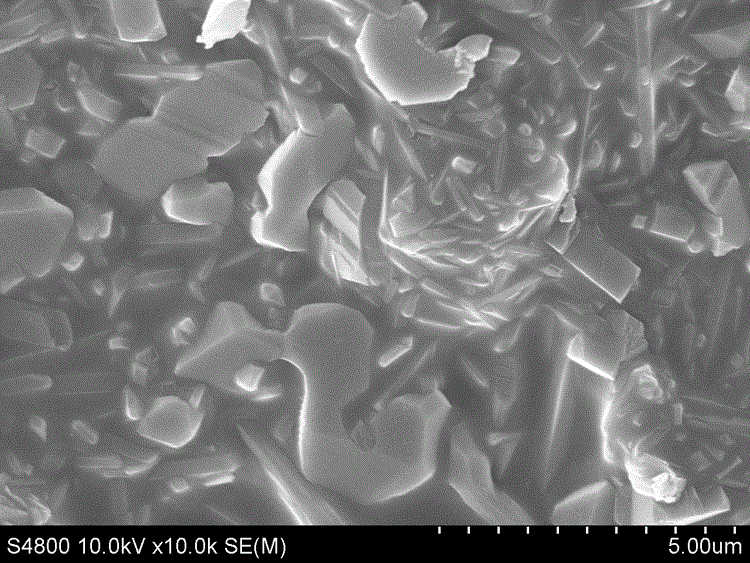

[0029] like figure 1 and Figure 4 Shown, a kind of coal gangue prepares ceramsite proppant for coalbed methane well, it comprises coal gangue and bauxite, is characterized in that:

[0030] The composition of the coal gangue raw material and its weight percentage content are: Al 2 o 3 The content is 23.3%, SiO 2 The content is 65%, K 2 O content is 5%, Fe 2 o 3 The content is 5%, and the content of other unavoidable impurities is 1.7%;

[0031] The composition of the bauxite raw material and its weight percent content are: Al 2 o 3 The content is 64.8%, SiO 2 The content is 20%, Fe 2 o 3 The content is 10%, TiO 2 The content is 5%, and the content of other unavoidable impurities is 0.2%;

[0032] The raw material composition and weight percentage content of the ceramsite proppant are: 90% of coal gangue and 10% of bauxite.

[0033] The composition and weight percentage of each phase in the ceramsite proppant are as follows: the content of the quartz phase is 31....

Embodiment 2

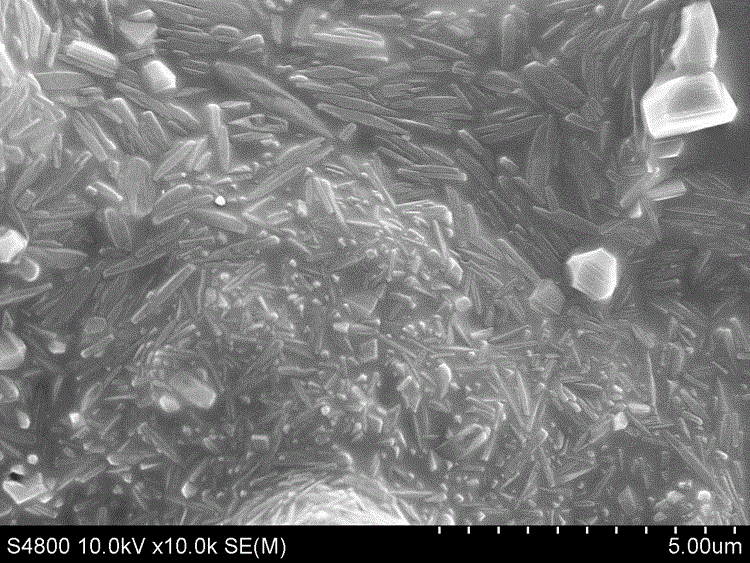

[0042] like figure 2Shown, a kind of coal gangue prepares ceramsite proppant for coalbed methane well, it comprises coal gangue and bauxite, is characterized in that:

[0043] The composition of the coal gangue raw material and its weight percentage content are: Al 2 o 3 The content is 25%, SiO 2 The content is 65%, K 2 O content is 5%, Fe 2 o 3 The content is 4.5%, and the content of other unavoidable impurities is 0.5%;

[0044] The composition of the bauxite raw material and its weight percent content are: Al 2 o 3 The content is 58%, SiO 2 The content is 20%, Fe 2 o 3 The content is 10%, TiO 2 The content is 5%, and the content of other unavoidable impurities is 1%;

[0045] The raw material composition and weight percentage content of the ceramsite proppant are: 87% of coal gangue and 13% of bauxite.

[0046] The weight percentage content of the ceramsite proppant is as follows: the content of quartz is 32.7%, the content of mullite is 42.5%, and the content...

Embodiment 3

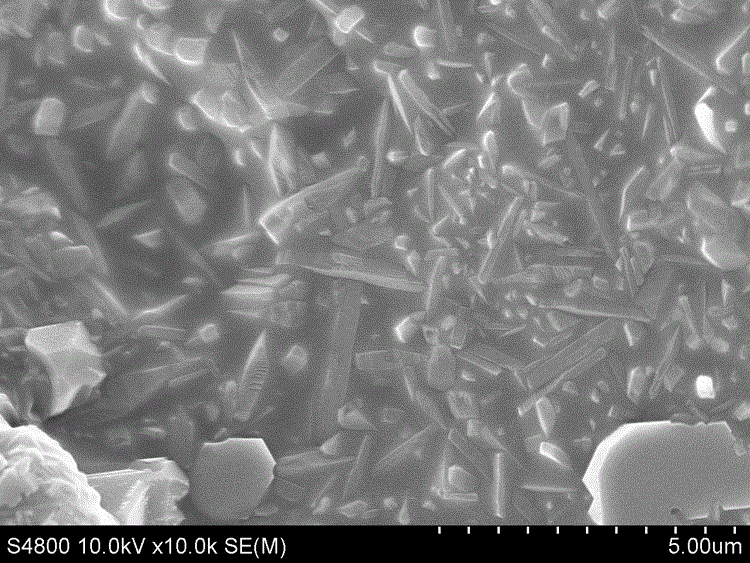

[0055] like image 3 Shown, a kind of coal gangue prepares ceramsite proppant for coalbed methane well, it comprises coal gangue and bauxite, is characterized in that:

[0056] The composition of the coal gangue raw material and its weight percentage content are: Al 2 o 3 The content is 20%, SiO 2 The content is 70%, K 2 O content is 4%, Fe 2 o 3 The content is 1%, and the content of other unavoidable impurities is 1%;

[0057] The composition of the bauxite raw material and its weight percent content are: Al 2 o 3 The content is 58%, SiO 2 The content is 26%, Fe 2 o 3 The content is 10%, TiO 2 The content is 5%, and the content of other unavoidable impurities is 1%;

[0058] The raw material composition and weight percentage content of the ceramsite proppant are: 80% coal gangue and 20% bauxite.

[0059] The weight percentage content of the ceramsite proppant is as follows: the content of quartz is 29.3%, the content of mullite is 49.1%, and the content of amorph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crush indicators | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com